I direct this to Watrob---and any one with knowledge of drum to disc brake conversion in Queensland. I am talking about a complete rebuilt FJ40 ute / fixed camper that is constantly fully loaded, for long road travel, and medium bush use.

This has been finished six years ago and never been out of the shed. (Read that as working 12/7 weeks).

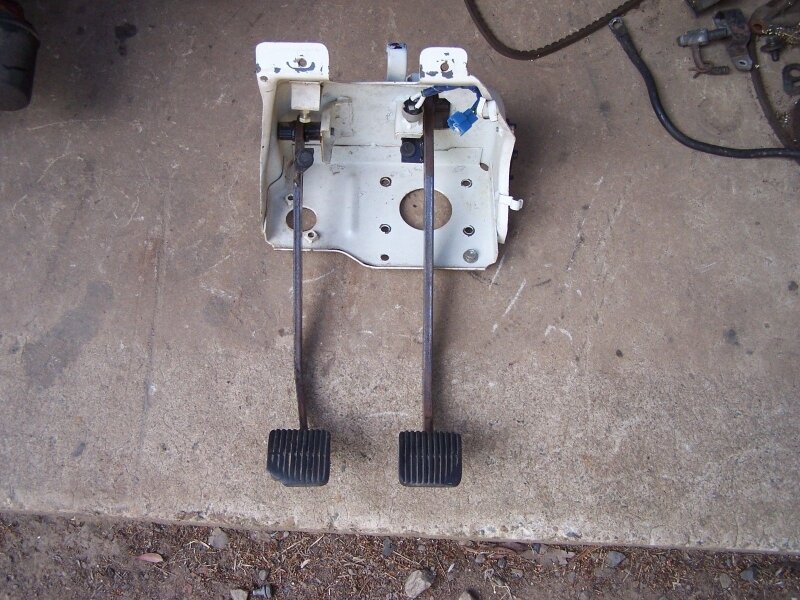

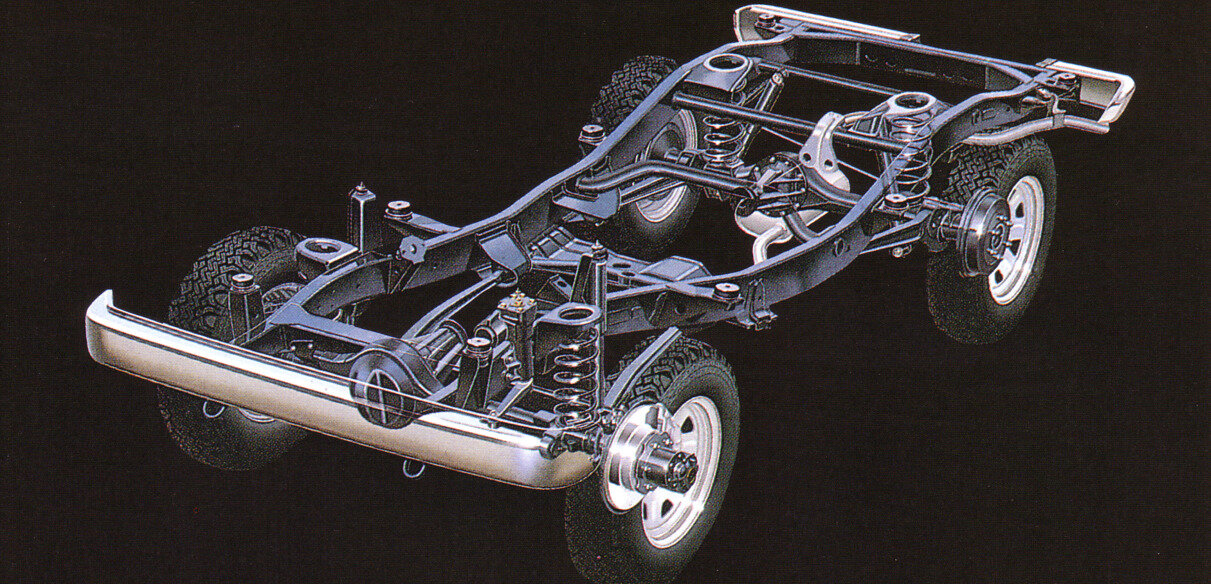

1) I have done the research on using 60 front hubs, OR manufacturing my own caliper brackets. Rear caliper mounts would be same as watrob has done. Hopper stoppers make similar, that is easy for me to make.

2) Seeking answers to certification, registration acceptance, and any/all difficulties encountered before I begin. This ute is not currently registered. Should I register it as a standard braking system, then make changes later.

3) Information on re-sleeving / undersizing rear calipers from standard front calipers to allow proportioning.

4) Does any one have knowledge of a certification engineer in Hervey Bay / Wide Bay area.

5) I have read the Queensland Transport, vehicle standards instruction, re. Land cruiser conversions, but that only deals with rear conversion on 80&100 series, where rear drum failure was prevalent in mining situations. The department has given authority to Hopper stoppers in this regard only.

6) I am sure I am not the first to need this information. So some one out there has been there and done it.

7) The change over is not so difficult. It is more of a question of remaining legal and insurable in this modern age.

I am not looking at spending a lot of money on this. All assistance welcomed. Chick

This has been finished six years ago and never been out of the shed. (Read that as working 12/7 weeks).

1) I have done the research on using 60 front hubs, OR manufacturing my own caliper brackets. Rear caliper mounts would be same as watrob has done. Hopper stoppers make similar, that is easy for me to make.

2) Seeking answers to certification, registration acceptance, and any/all difficulties encountered before I begin. This ute is not currently registered. Should I register it as a standard braking system, then make changes later.

3) Information on re-sleeving / undersizing rear calipers from standard front calipers to allow proportioning.

4) Does any one have knowledge of a certification engineer in Hervey Bay / Wide Bay area.

5) I have read the Queensland Transport, vehicle standards instruction, re. Land cruiser conversions, but that only deals with rear conversion on 80&100 series, where rear drum failure was prevalent in mining situations. The department has given authority to Hopper stoppers in this regard only.

6) I am sure I am not the first to need this information. So some one out there has been there and done it.

7) The change over is not so difficult. It is more of a question of remaining legal and insurable in this modern age.

I am not looking at spending a lot of money on this. All assistance welcomed. Chick