- Joined

- Feb 2, 2013

- Messages

- 16,240

For the boat which of course has no repair manual and having just been told by real marine engineers the boat had to travel a week to find that pretty much everything pretend marine engineers in the Isle of Man fitted or repaired umpteen times in the past 2 years is loose .

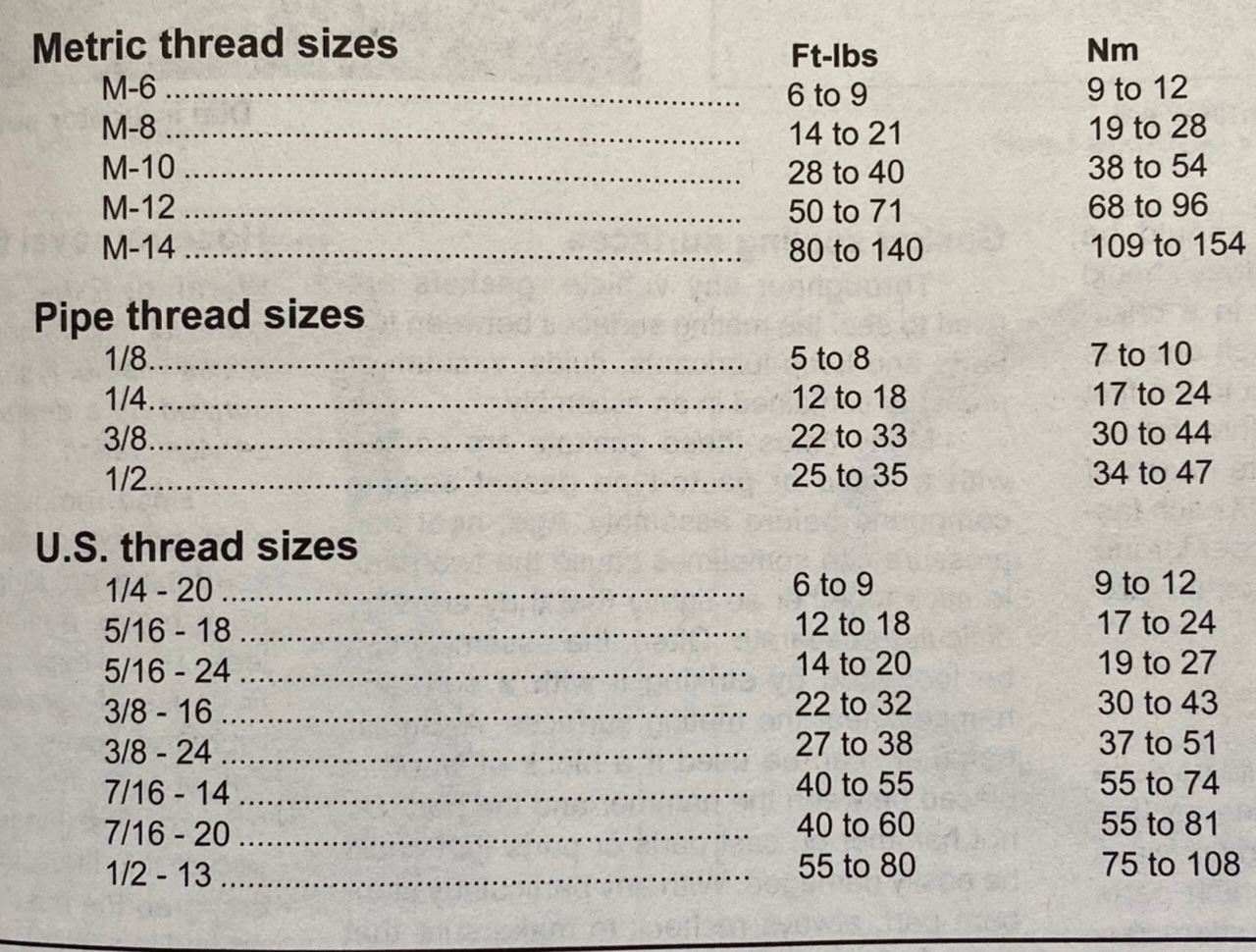

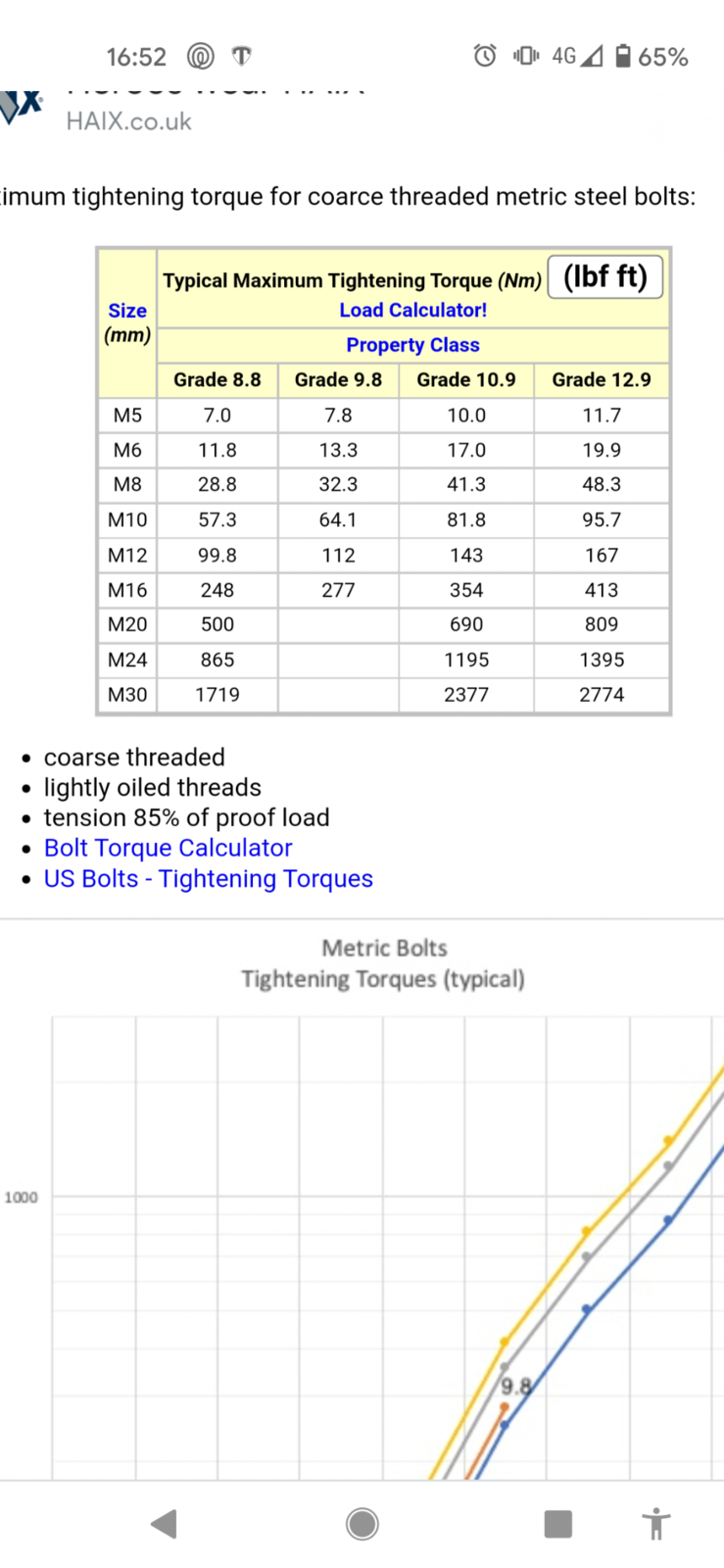

I'm thinking maybe there should be a torque wrench aboard permanently set to "tight" but what setting when it might be used on anything from M6 to M14 ?

Tell a fisherman to make sure its tight pretty much ensures he will snap the bolt so i hope to save both him and me some headaches .

Your thoughts please .

I'm thinking maybe there should be a torque wrench aboard permanently set to "tight" but what setting when it might be used on anything from M6 to M14 ?

Tell a fisherman to make sure its tight pretty much ensures he will snap the bolt so i hope to save both him and me some headaches .

Your thoughts please .