I have a problem on my ’95 80 where the front wheel camber angle on the RHS is noticeably positive camber compared with the LHS wheel. It’s a left hooker so the RHS is the nearside/kerbside, but that’s of no consequence. I have had everything on the front axle overhauled with new parts by my local friendly 4x4 service (thanks GTC at Popesti-Leordeni, ILFOV, Str. Sf. Nicolae Nr. 4C) but still have the problem.

Their only suggestion was a bent axle casing. This may not be too surprising as 6 years ago some idiot did hit me full on that hub at about 80 kph totally destroying his Dacia Logan, but there was no visible damage to the cruiser or my old girl’s axle. Anyway, conclusion is the casing’s bent and with no scrapyard/breaker with TLC’s (you lucky guys in the UK where there’s loads of them … hi Karl…) it was a case of do something with my axle or not at all.

… hi Karl…) it was a case of do something with my axle or not at all.

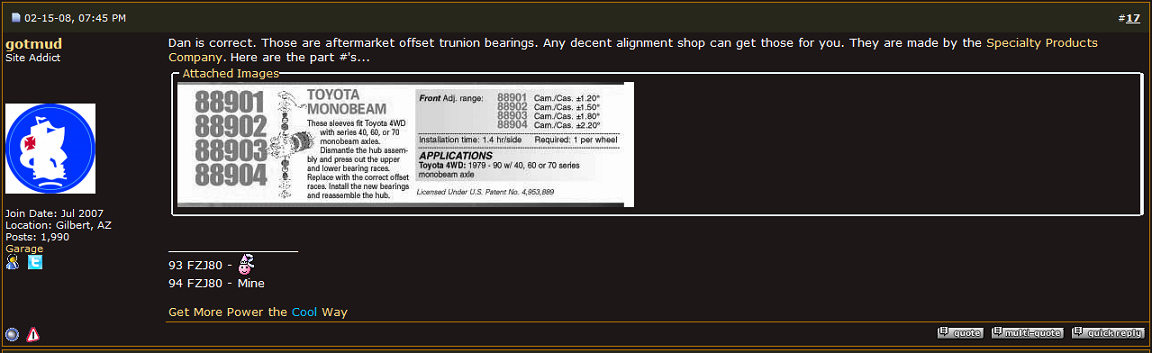

Anyway after months of searching, I came across this old 2007 thread on IH8MUD

[attachment=0:1frlesvj]Offset trunion bearings 2.png[/attachment:1frlesvj]

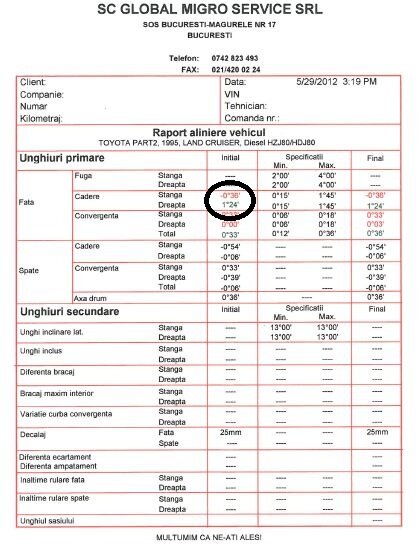

A chance at last I thought to solve my problem, offset camber/caster bearings, what a good idea!. They offer a range of angle adjustments that can be achieved, so I found an alignment workshop and had the old girl measured up.

LHS Camber -0.36 degrees (negative camber)

RHS Camber +1.45 degrees (positive camber)

If nothing else it proved I wasn’t going squint in my old age, secondly it showed that the RHS camber was way off, compared with the LHS. Surprisingly, the print-out also confirmed that the factory tolerance was within range on the RHS but out of range on the LHS! TLC’s are supposed to have rakes of positive camber… can that be right? Comments may be helpful.

Anyway I decided to try to adjust the alignment with these new-found offset camber/caster bearings and bring the RHS camber as close to the camber angle on the LHS as I could. That meant 2.2 degrees to the RHS to bring it close to the LHS camber angle.

I tell you, such a positive camber looks really weird on a cruiser and I’ve never noticed any other truck looking like a Hillman Imp on steroids. It drives OK but that tyre always scrubs on the outside, needing regular rotation to keep them even. All annoying stuff.

So, I contacted Jeff Hargash at Speciality Products Company 4045 Speciality Place, Longmont, Colorado 80504 USA (tel: 8005256505) and he’s a great guy, very attentive and helpful. I gave him my angles and he confirmed that the 2.2 degree set that I wanted to order would do the trick. I made an internet banking transfer for the $51.18 + $25.95 shipping and waited for the bearings to arrive.

10 days for delivery from the USA to Romania was pretty good I thought, so I very excitedly took them to my Service for fitting (Sadly I don't have any facilities or spare time for DIY ).

).

Bugger damn, the bearings don’t fit. They’re too small, they’re for a 70 not an 80 axle. If only I'd read the post on IH8MUD more closely.

They’re too small, they’re for a 70 not an 80 axle. If only I'd read the post on IH8MUD more closely.

So, another e-mail to Jeff with the bad news. Kindly, he’s contacted their R&D and they’re going to measure up an 80 axle that they have in the workshop and try to make me a pair of 2.2 degree sleeves (as he calls them).

If anyone is interested in these offset bearings, drop Jeff an e-mail.

I’ll post on this thread if I ever get bearings made up that fit, otherwise I’ll have to make do with my old girl having bandy front wheels for ever.

Their only suggestion was a bent axle casing. This may not be too surprising as 6 years ago some idiot did hit me full on that hub at about 80 kph totally destroying his Dacia Logan, but there was no visible damage to the cruiser or my old girl’s axle. Anyway, conclusion is the casing’s bent and with no scrapyard/breaker with TLC’s (you lucky guys in the UK where there’s loads of them

Anyway after months of searching, I came across this old 2007 thread on IH8MUD

[attachment=0:1frlesvj]Offset trunion bearings 2.png[/attachment:1frlesvj]

A chance at last I thought to solve my problem, offset camber/caster bearings, what a good idea!. They offer a range of angle adjustments that can be achieved, so I found an alignment workshop and had the old girl measured up.

LHS Camber -0.36 degrees (negative camber)

RHS Camber +1.45 degrees (positive camber)

If nothing else it proved I wasn’t going squint in my old age, secondly it showed that the RHS camber was way off, compared with the LHS. Surprisingly, the print-out also confirmed that the factory tolerance was within range on the RHS but out of range on the LHS! TLC’s are supposed to have rakes of positive camber… can that be right? Comments may be helpful.

Anyway I decided to try to adjust the alignment with these new-found offset camber/caster bearings and bring the RHS camber as close to the camber angle on the LHS as I could. That meant 2.2 degrees to the RHS to bring it close to the LHS camber angle.

I tell you, such a positive camber looks really weird on a cruiser and I’ve never noticed any other truck looking like a Hillman Imp on steroids. It drives OK but that tyre always scrubs on the outside, needing regular rotation to keep them even. All annoying stuff.

So, I contacted Jeff Hargash at Speciality Products Company 4045 Speciality Place, Longmont, Colorado 80504 USA (tel: 8005256505) and he’s a great guy, very attentive and helpful. I gave him my angles and he confirmed that the 2.2 degree set that I wanted to order would do the trick. I made an internet banking transfer for the $51.18 + $25.95 shipping and waited for the bearings to arrive.

10 days for delivery from the USA to Romania was pretty good I thought, so I very excitedly took them to my Service for fitting (Sadly I don't have any facilities or spare time for DIY

).

).Bugger damn, the bearings don’t fit.

So, another e-mail to Jeff with the bad news. Kindly, he’s contacted their R&D and they’re going to measure up an 80 axle that they have in the workshop and try to make me a pair of 2.2 degree sleeves (as he calls them).

If anyone is interested in these offset bearings, drop Jeff an e-mail.

I’ll post on this thread if I ever get bearings made up that fit, otherwise I’ll have to make do with my old girl having bandy front wheels for ever.

There's no play in anything on this axle (except the diff

There's no play in anything on this axle (except the diff