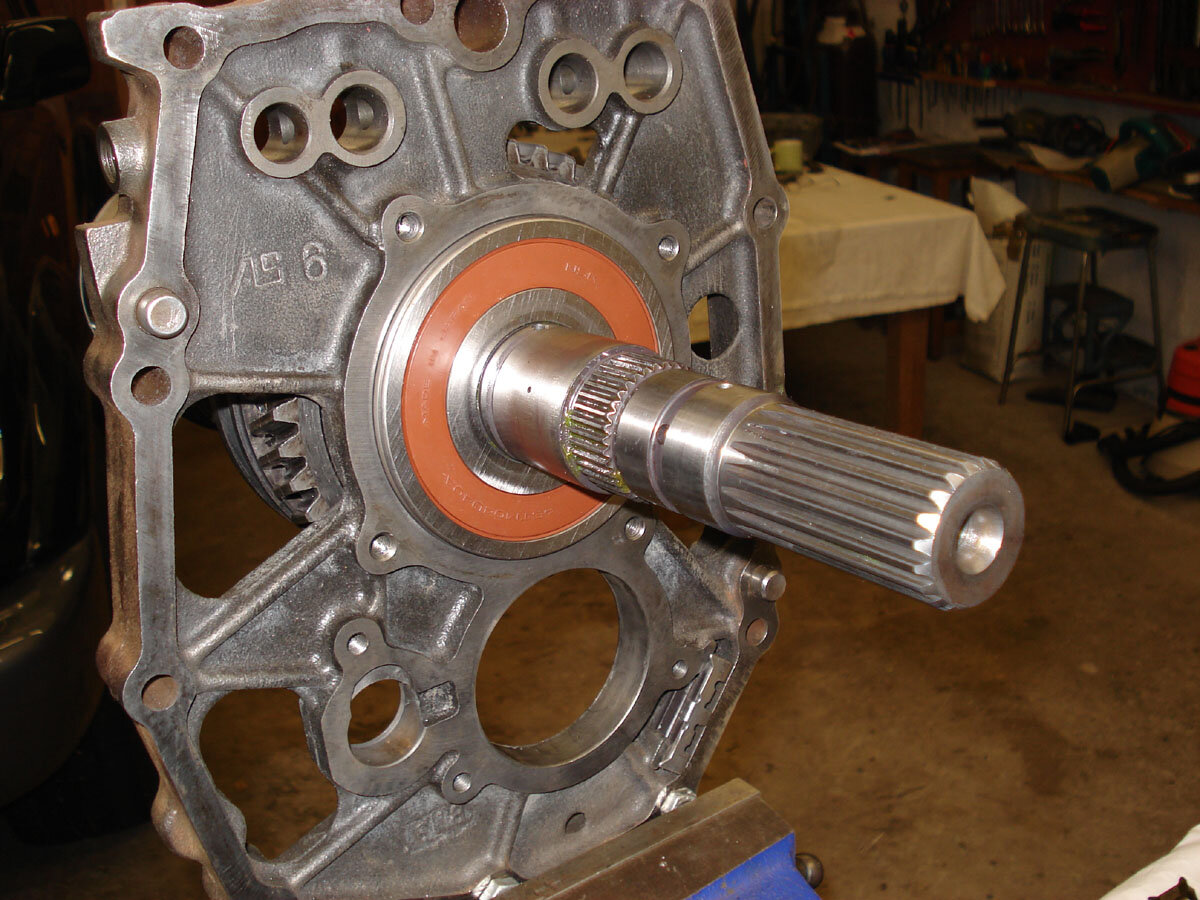

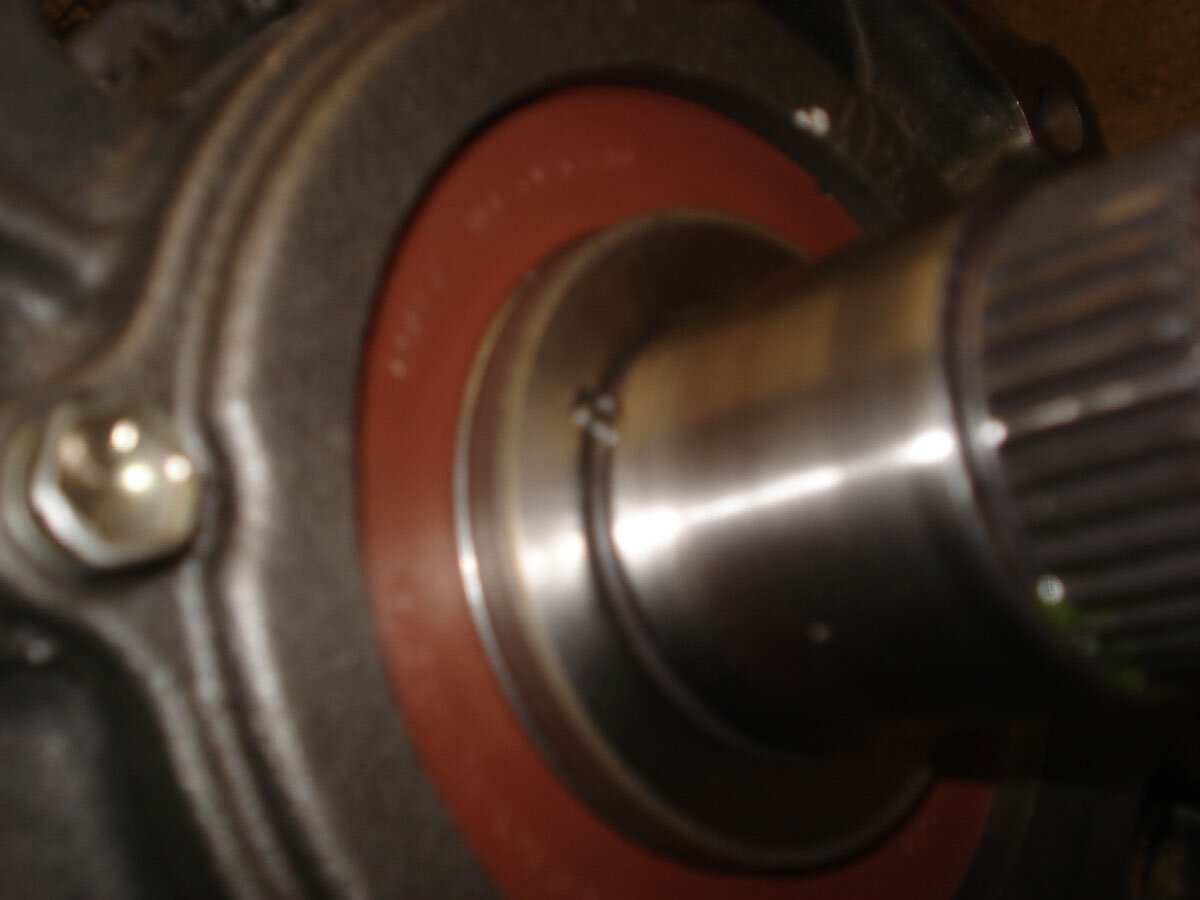

Time for a separate thread for this I think, Frank's rebuild of Ian's old box, starting soon and will be documented here. To recap, the box in question was rebuilt a few times by a 'specialist' but it had some issues. Frank took the box to bits and found "Most of the syncro rings are chewed and have been spinning past their three sprung locators. Also the output shaft thrust bearing is broken into 3 pieces. Some of the syncro hubs have been put on the wrong way round" ... and other problems, not good for a specialist rebuild!

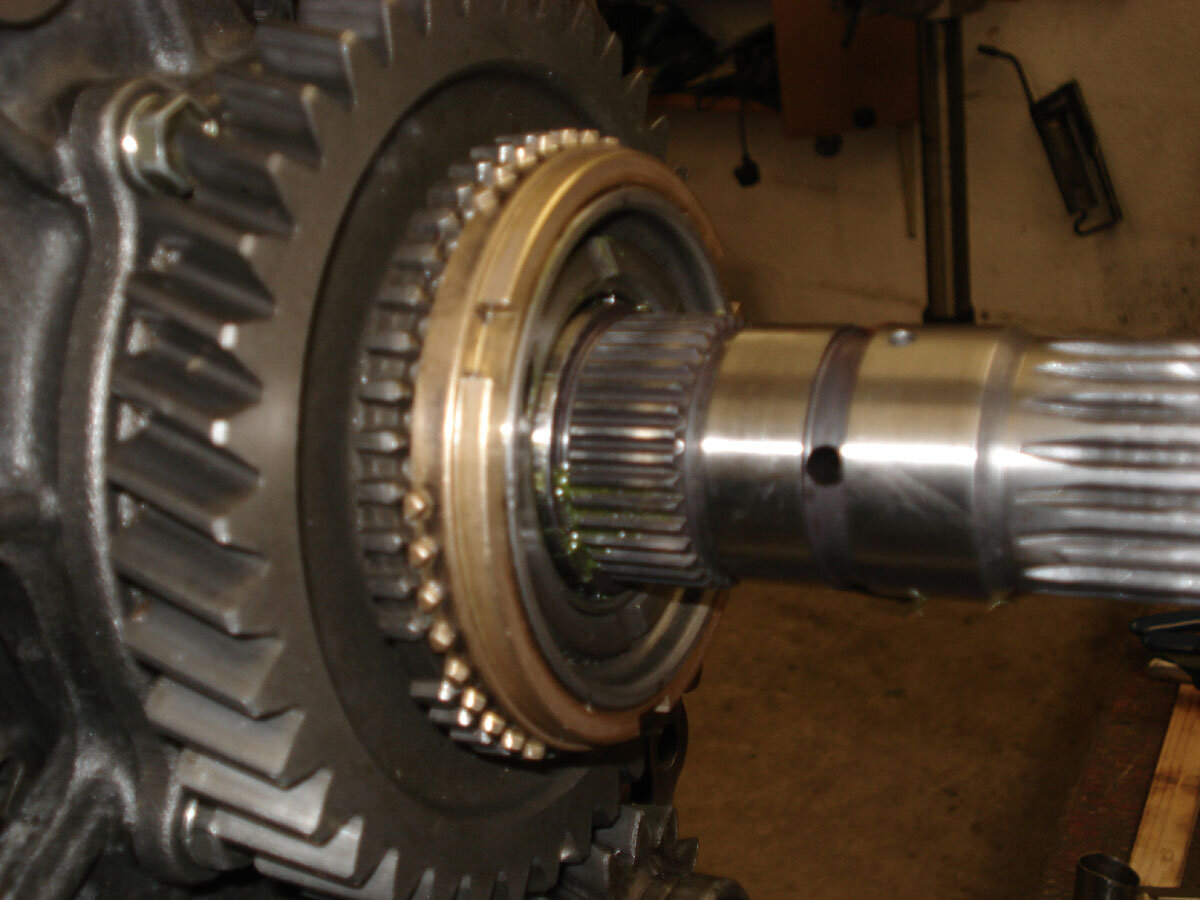

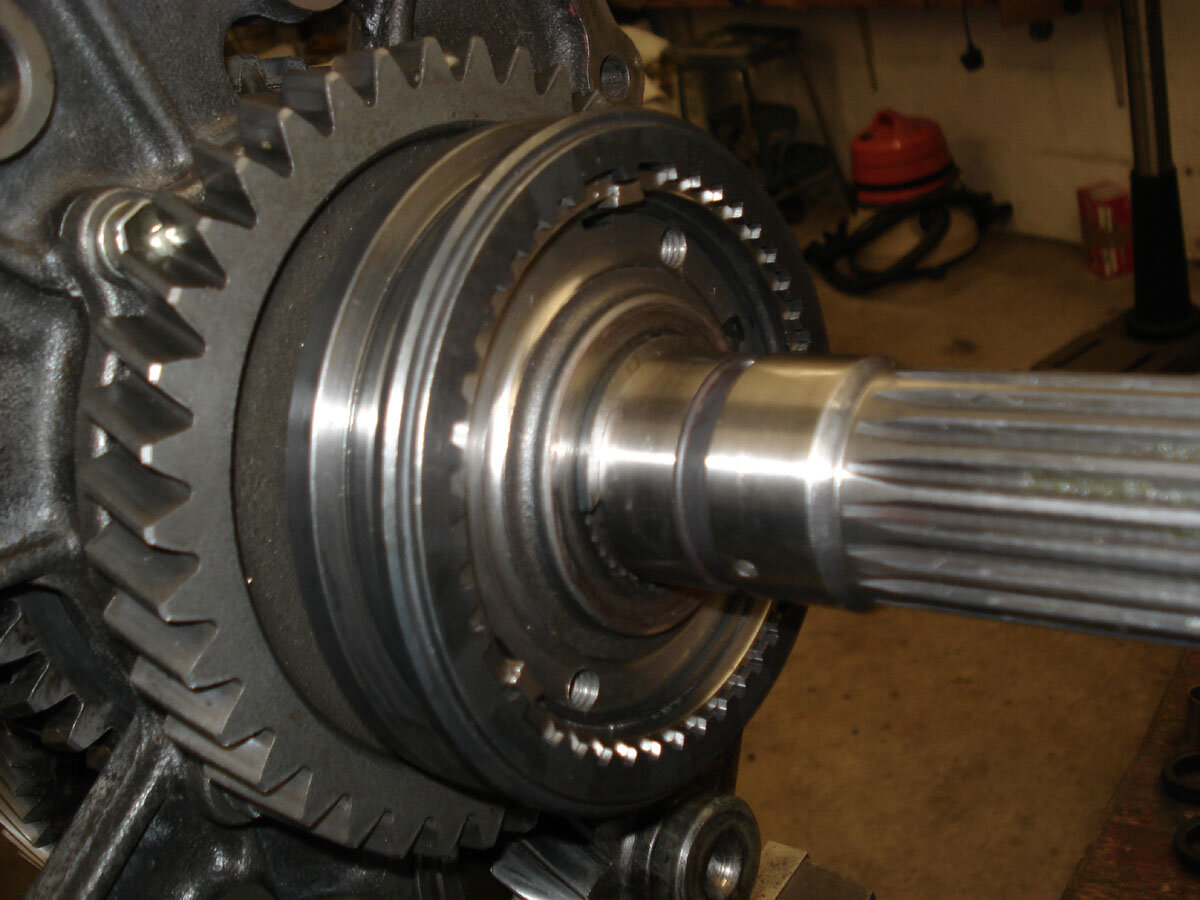

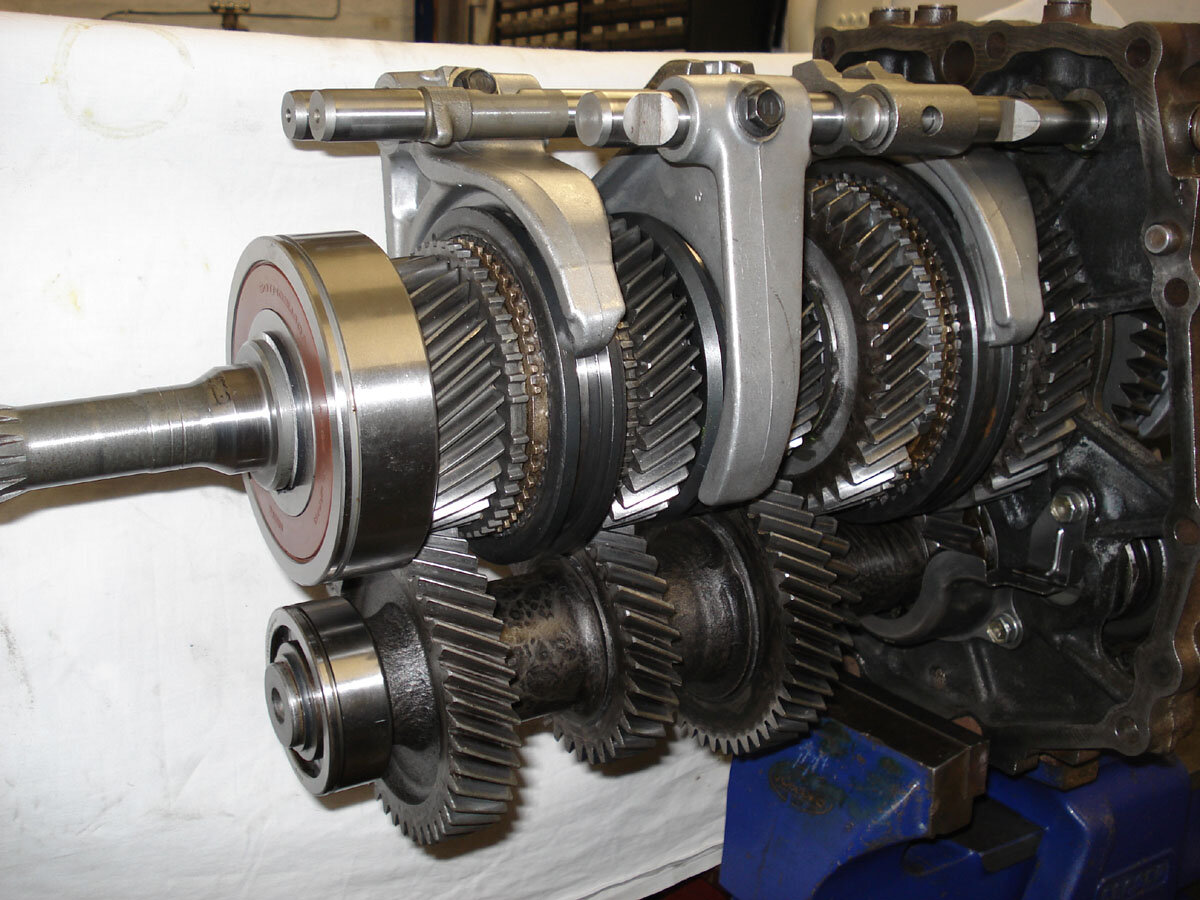

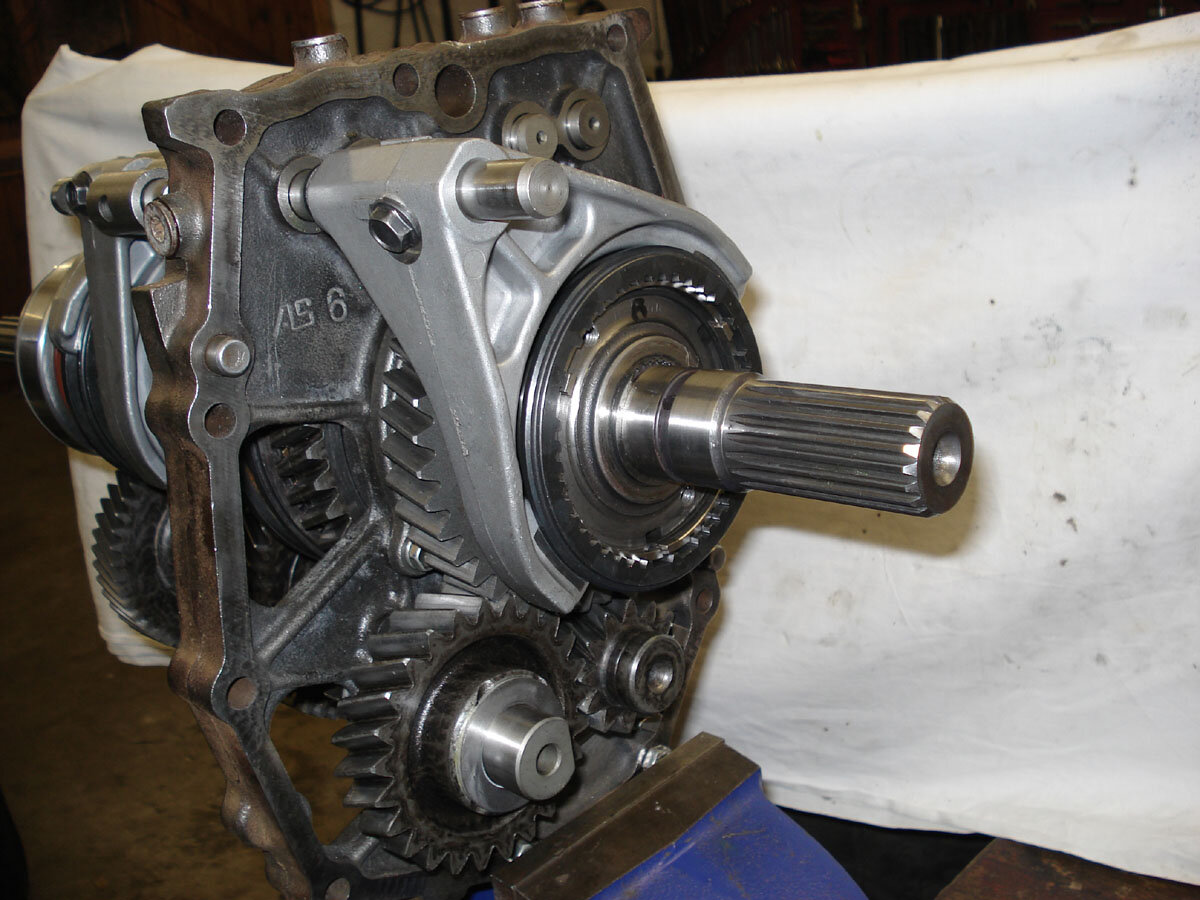

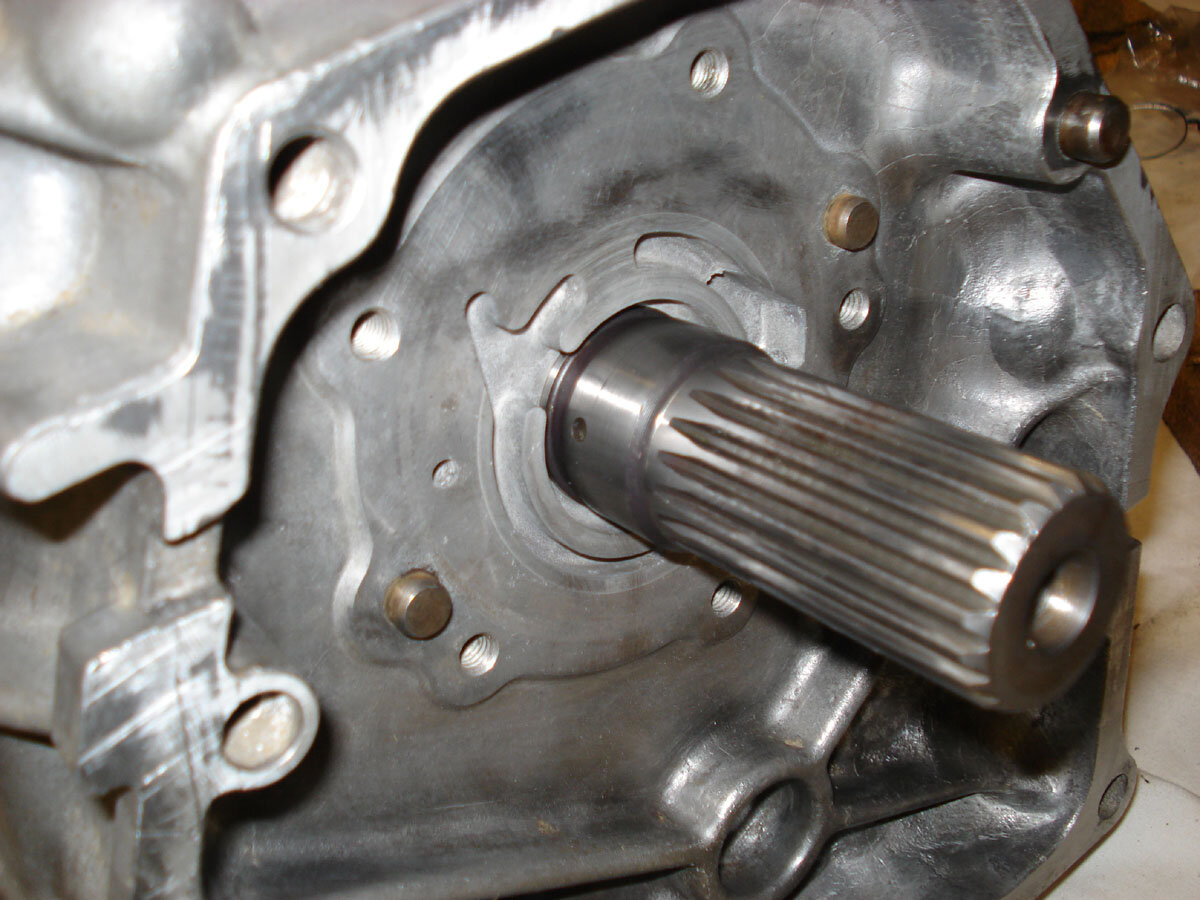

The box in bits showing some of the damaged components:

the 1st & 2nd gear synchros are also so worn as to be useless, not sure if they are just old or another casualty of the poor rebuild.

The box in bits showing some of the damaged components:

the 1st & 2nd gear synchros are also so worn as to be useless, not sure if they are just old or another casualty of the poor rebuild.

Last edited:

.

.