mjmcgowan

New Member

- Joined

- Dec 7, 2010

- Messages

- 33

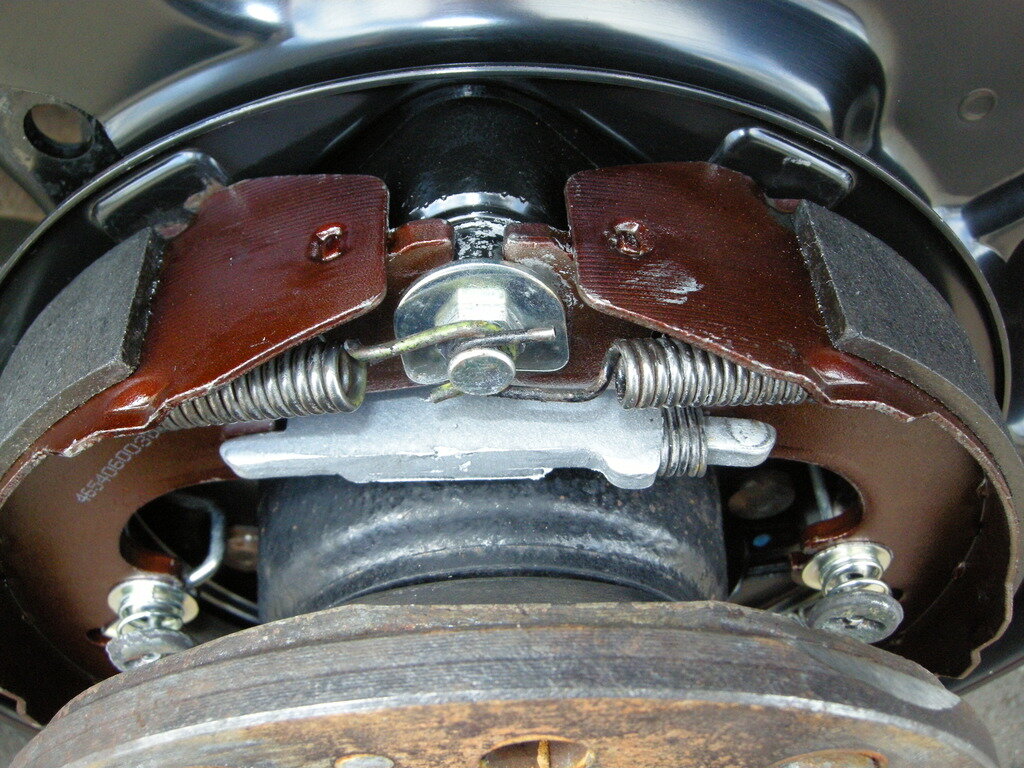

My handbrake has not been working for a while and no one has been able to get it working for any length of time below is the repairs we have carried out:

Australia - replaced pads, springs, clips and handbrake cable (aftermarket milner) the cable was slightly too long so we used some spacers, seemed to work for 9 months.

Colombia - Handbrake ceased and was missing shoe holding pins - fixed and worked for 3 months

South Africa - Replaced pins and hand brake cable (aftermarket milner) worked for a couple of weeks, toyota said was the cable being too long, had it shortened, but was too short, replaced with Toyota cable still too long... about two inches.... handbrake did not work since,

Turkey - Replaced pads and replaced pad return springs both sides, looks like the pads are not balanced and the right hand side is not to taught i.e the bell crank spring is not pulling on the main cable and the crank maybe a little ceased...

We are returning to the UK and need to have it fixed properly prior to an MOT,

Can anyone recommend which parts we should look at replacing... how to balance the pads correctly and has anyone else found either Milner or Toyota cable are too long from the outset?

Thanks for your help

Australia - replaced pads, springs, clips and handbrake cable (aftermarket milner) the cable was slightly too long so we used some spacers, seemed to work for 9 months.

Colombia - Handbrake ceased and was missing shoe holding pins - fixed and worked for 3 months

South Africa - Replaced pins and hand brake cable (aftermarket milner) worked for a couple of weeks, toyota said was the cable being too long, had it shortened, but was too short, replaced with Toyota cable still too long... about two inches.... handbrake did not work since,

Turkey - Replaced pads and replaced pad return springs both sides, looks like the pads are not balanced and the right hand side is not to taught i.e the bell crank spring is not pulling on the main cable and the crank maybe a little ceased...

We are returning to the UK and need to have it fixed properly prior to an MOT,

Can anyone recommend which parts we should look at replacing... how to balance the pads correctly and has anyone else found either Milner or Toyota cable are too long from the outset?

Thanks for your help

Last edited: