Finiterex

Well-Known Member

- Joined

- Jun 16, 2019

- Messages

- 373

- Country Flag

Haha me too!Looking forward to seeing the finished truck

Haha me too!Looking forward to seeing the finished truck

Anyone had any experience with LineX - https://linex.com/specialty-automotive

Wish I could afford the stuff but too pricey for me! Raptor will have to do.Yes. Every part of my 80 is covered with Line X. Just the other day I side swiped a pine tree branch..there should have been a massive scratch down the side...the branch came of worse. Haven´t quite worked out how to clean Line X..power wash is the way but it leaves zebra stripes if you miss bits. Definitely a dirt magnet.

Cheers @AndycruiserguyLomas... For the life of me I can't find a cruiser video... Have you got a link?Look on you tube, I've done loads of Cruiser calipers but did see a clip somewhere how to do it easily. When you see it becomes easy.

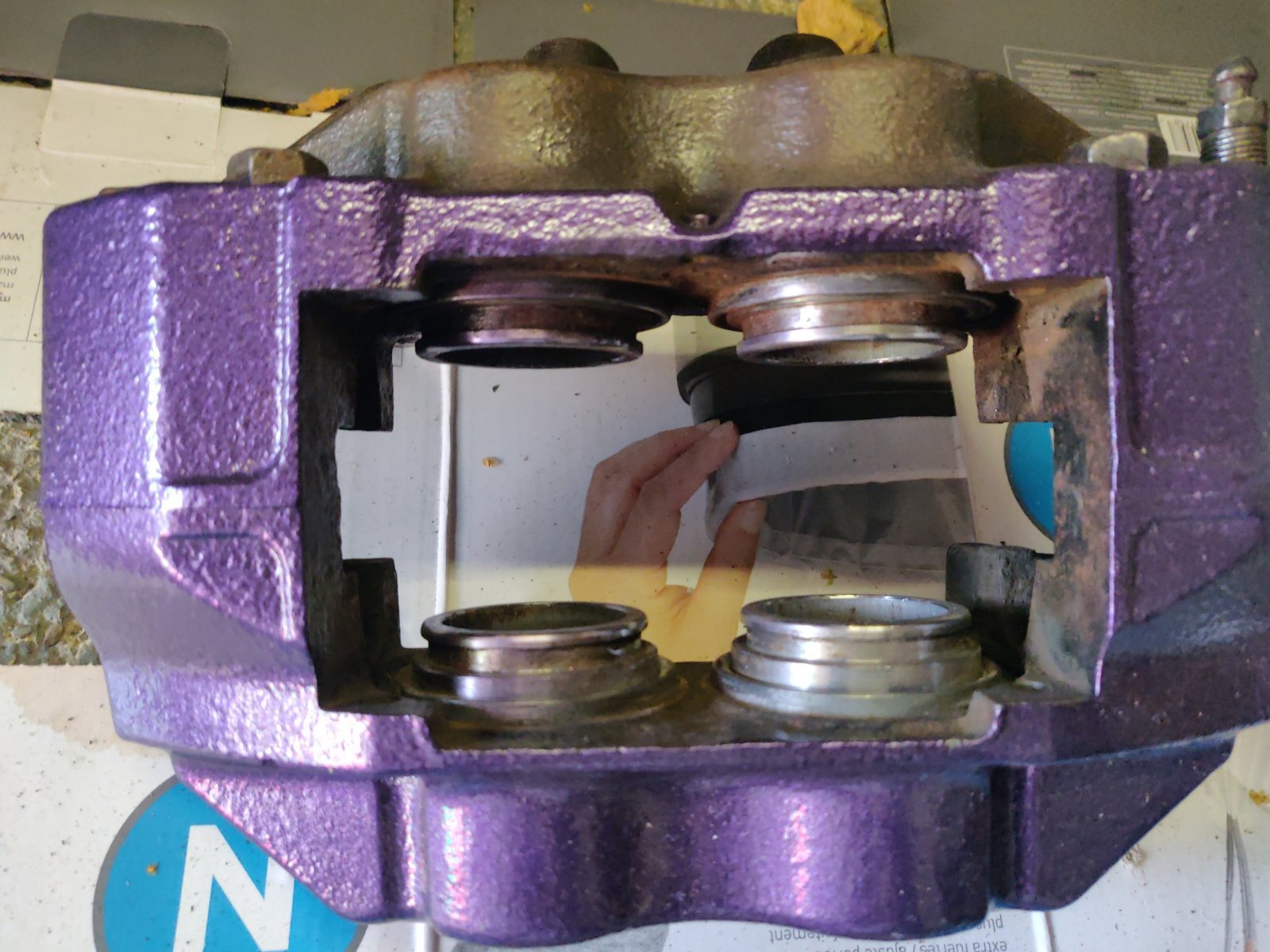

Hey Andy... My pistons aren't out... They look like this..I don't as I can't remember where I saw it. From memory I think you put the top of the boot just over the bottom of the piston, then just put the bottom of the boot in place on the caliper. Push the piston into place, the top of the boot slides up the piston and snaps into place as the piston gets to the bottom of its travel. I did the pistons on my 80 calipers the other week and fitting them was a minutes job each piston.

Hey Andy... My pistons aren't out... They look like this..

Do they need to be out to fit the.rubber dust seals?

View attachment 158030

Tbh mate I really don't know. The old discs seamed evenly worn. The brake system is not in a state where I can plumb the calipers in at the minute so if you could advise me on how to do the job I'd be greatly appreciative (I've never stripped calipers down).Ah, good luck with that then. I've never tried putting them on in that position, every time after a piston out refurb. I assume you have checked the calipers for correct operation and that all pistons move equally when the pedal is pressed? Just one thing to bear in mind, if you want to remove the pistons with pedal power ( as I do) the pistons can be pressed out to just below their limit with the disc inbetween with the pads removed. This makes a lot easier job on the bench.

Indeed mate. We figured tank attaches to body... Body to that bit of chassis. Only other thing on it is the brake balance valve. As josh is gonna make new bumper anyway he figured easier to just run two new legs socketed from the rest of chassis... New bumper will act as cross member.Yikes , but then i suppose it only supports the body for load carrying and its main constant load is the fuel tank . I've always said a good weld is stronger than the steel its on .

Sounds much the same as mine mate!chassis back end is a know weakness.

I was alarmed when recovering a rally buggy to the finish line of this years Morocco Desert Challenge, the side I thought was better cracked and bent. Rusted through from the inside. The other side was held together by rust proofing and paint!