nathanrobo

Well-Known Member

- Joined

- Apr 6, 2010

- Messages

- 655

I've looked through a number of threads on the AHC suspension, but I still have a number of unanswered questions. I thought it would be good to have a step by step guide, for those who keep their trucks on standard system. Contributions would be really appreciated, particularly on TIS, on the sensors and settings for the Torsion Bars. This should provide answers to folk whose spheres need an overhaul, whose trucks may be leaning to one side or where the system is doing odd things.

I'm about to set up my own after stripping out the Torsion Bars, Control Arms (rear) with it's linkage, removing spheres and draining AHC. There's no hurry as I need to get a few miles on the truck to run the rebuilt engine in and MOT it (been off the road for nearly two years). But I thought some Techstream screenshots, pictures of the torsion bars, sphere's etc and an overview of the correct pressure settings / body heights would be helpful to anyone doing this for the first time.

I need help for the post because, although I have some experience of spheres (remember "stitch in time" thread) and after the recent strip down and reassembly. I know there are others with far greater depth of knowledge on this subject.

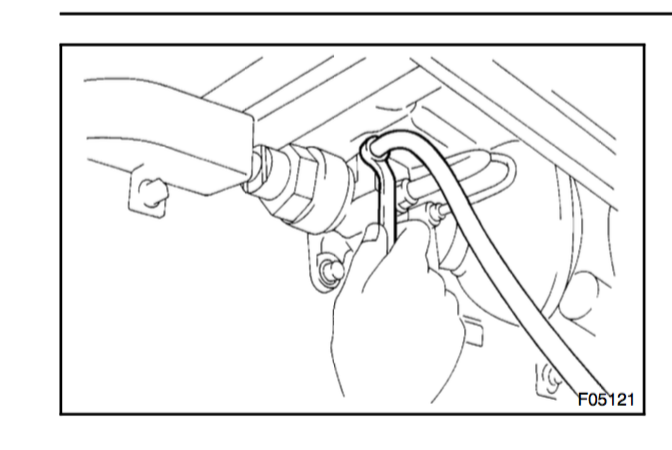

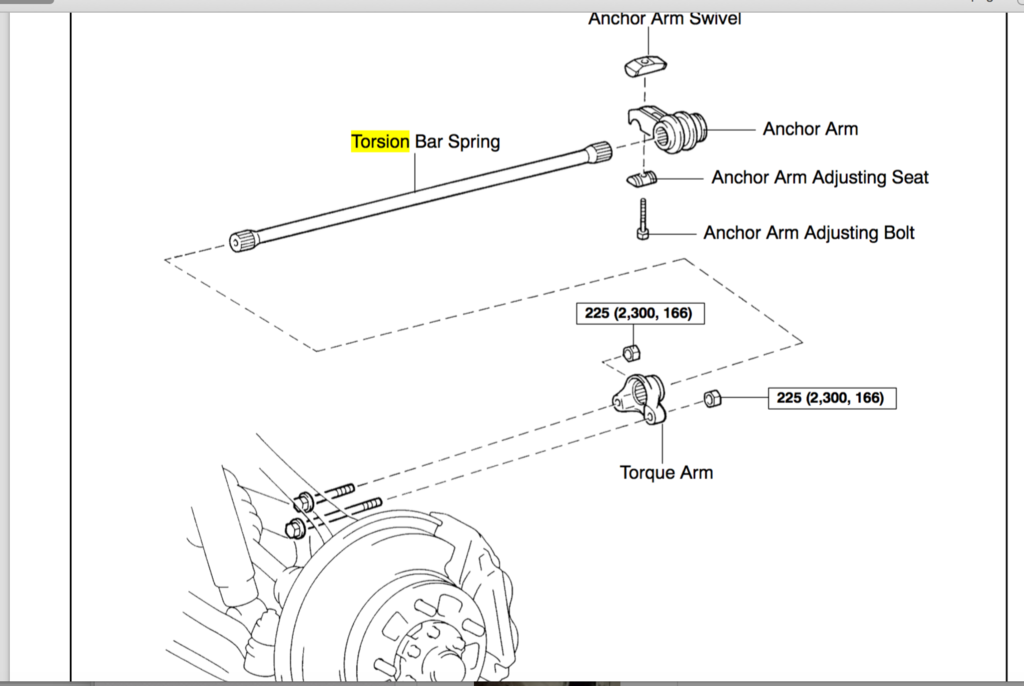

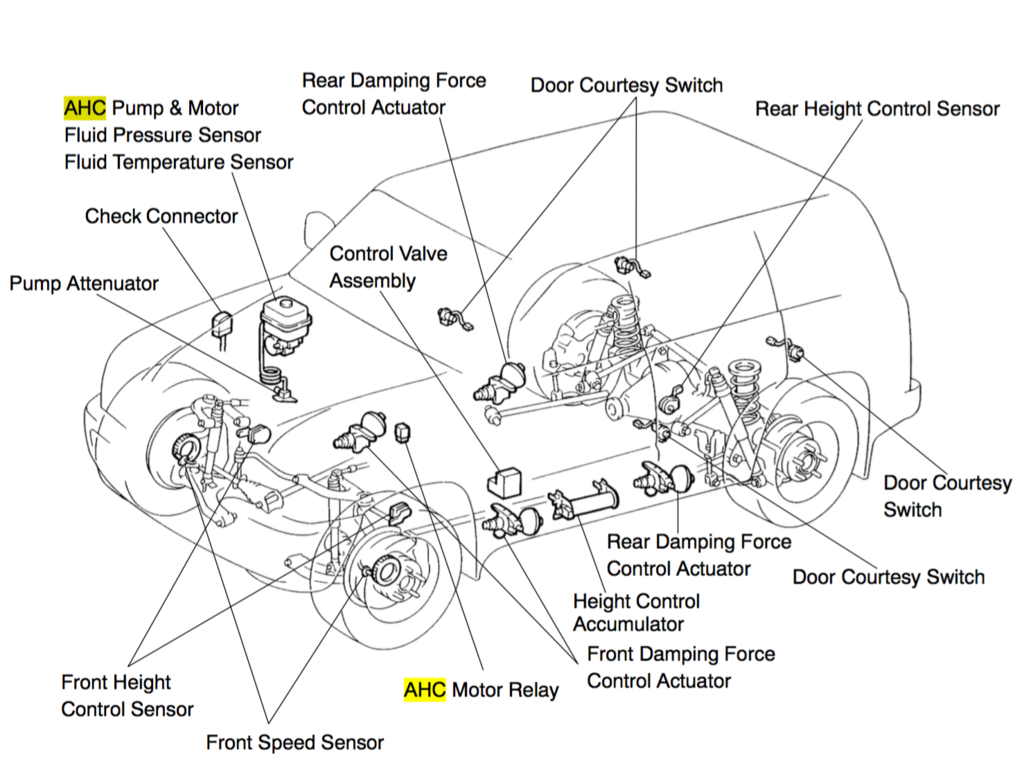

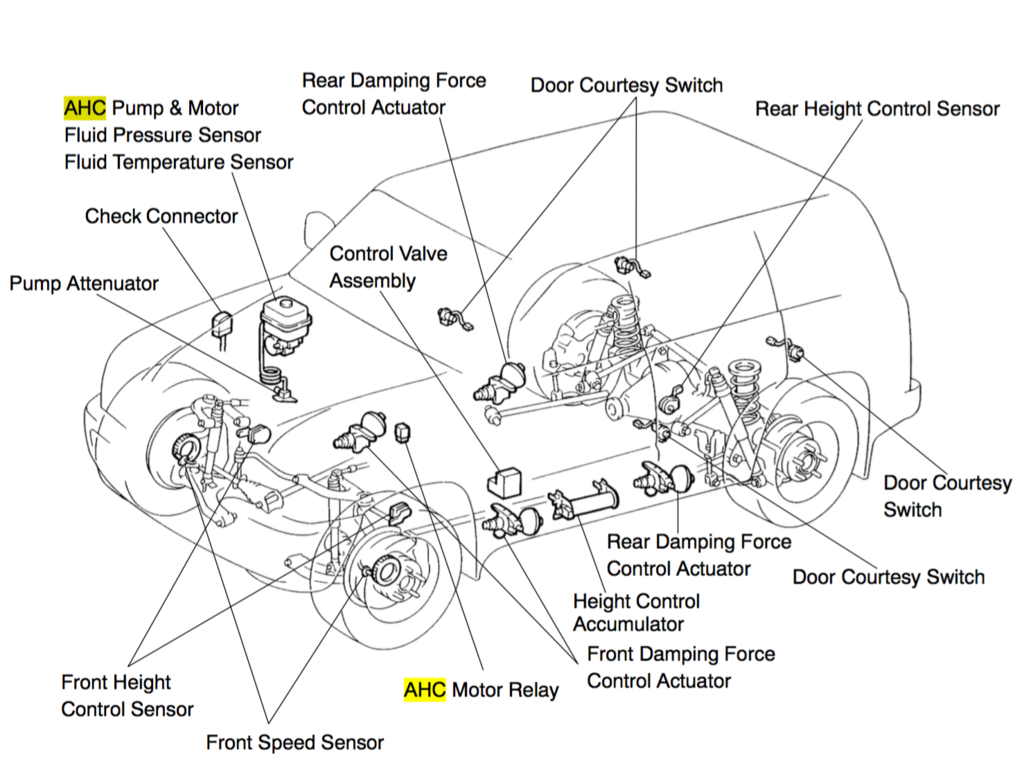

Overview of AHC hydraulic components

View attachment 110951

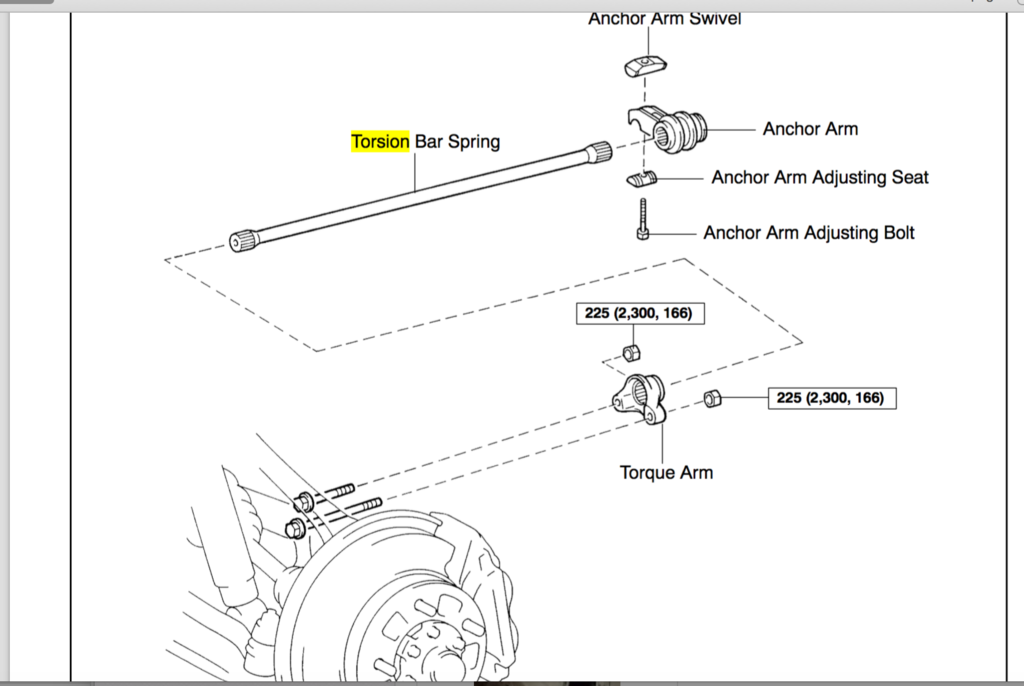

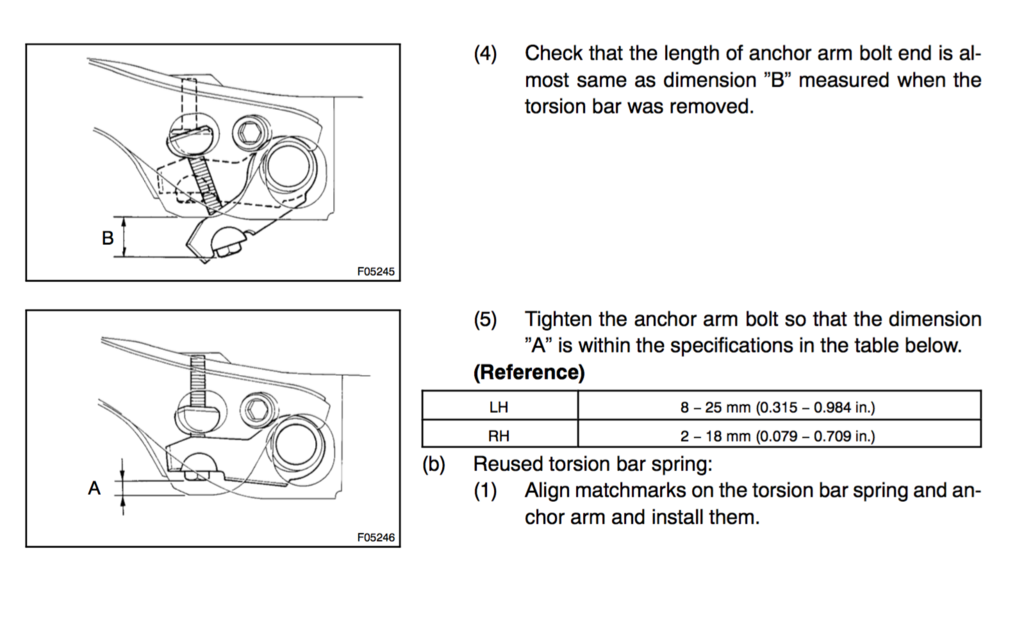

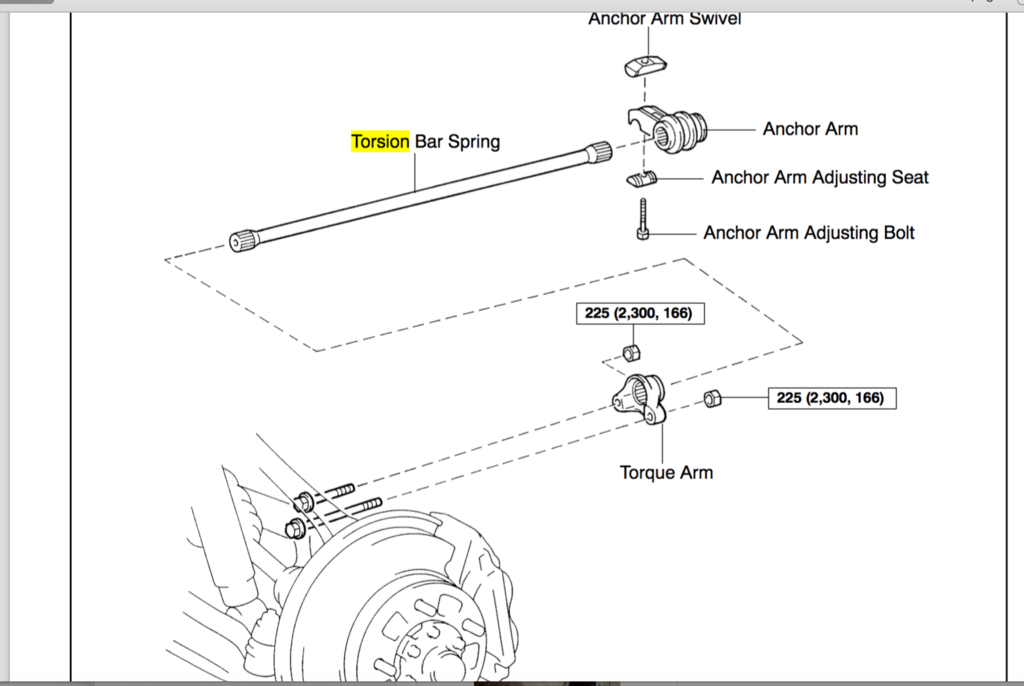

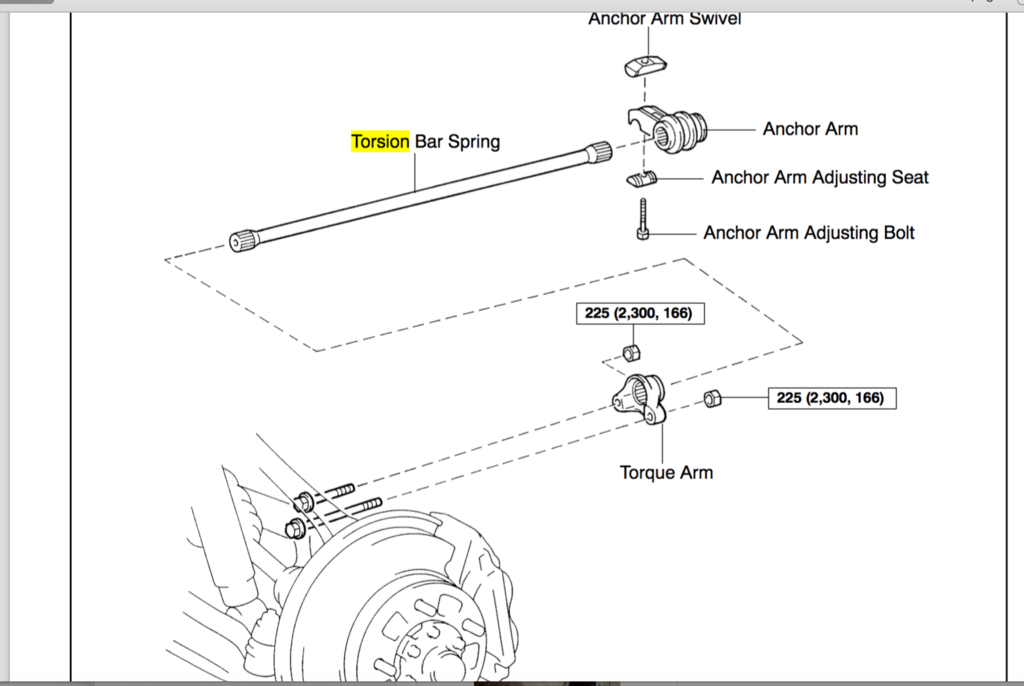

Overview of the torsion bar config

View attachment 110953

I'm about to set up my own after stripping out the Torsion Bars, Control Arms (rear) with it's linkage, removing spheres and draining AHC. There's no hurry as I need to get a few miles on the truck to run the rebuilt engine in and MOT it (been off the road for nearly two years). But I thought some Techstream screenshots, pictures of the torsion bars, sphere's etc and an overview of the correct pressure settings / body heights would be helpful to anyone doing this for the first time.

I need help for the post because, although I have some experience of spheres (remember "stitch in time" thread) and after the recent strip down and reassembly. I know there are others with far greater depth of knowledge on this subject.

Overview of AHC hydraulic components

View attachment 110951

Overview of the torsion bar config

View attachment 110953

Last edited: