dellboykev

Member

- Joined

- Aug 23, 2015

- Messages

- 147

- Country Flag

I did a little tinkering with my fuel pump over the weekend and i have taken a couple of pictures to try and clear a few things up for people the guides i used are lcool http://www.lcool.org/technical/80_series/1hdft_pump_adj.html and cptsideways http://www.landcruiserclub.net/foru...67-4-2-TD-Fuel-Pump-Tweakage-Some-useful-info

I have drawn a couple of arrows it is quite hard to take a picture of the screw that needs to be removed to adjust the toothed boost compensator this picture is from the back of the pump and the top arrow is the max off boost adjustment and the bottom arrow is the screw you need to remove to get to the boost compensator it has a vacuum pipe on the end of it

after fiddling round a little i did it a different way you only need a 13mm spanner, 5mm allen key, a long flat blade screw driver and an angle grinder the first thing i did was adjust my allen key

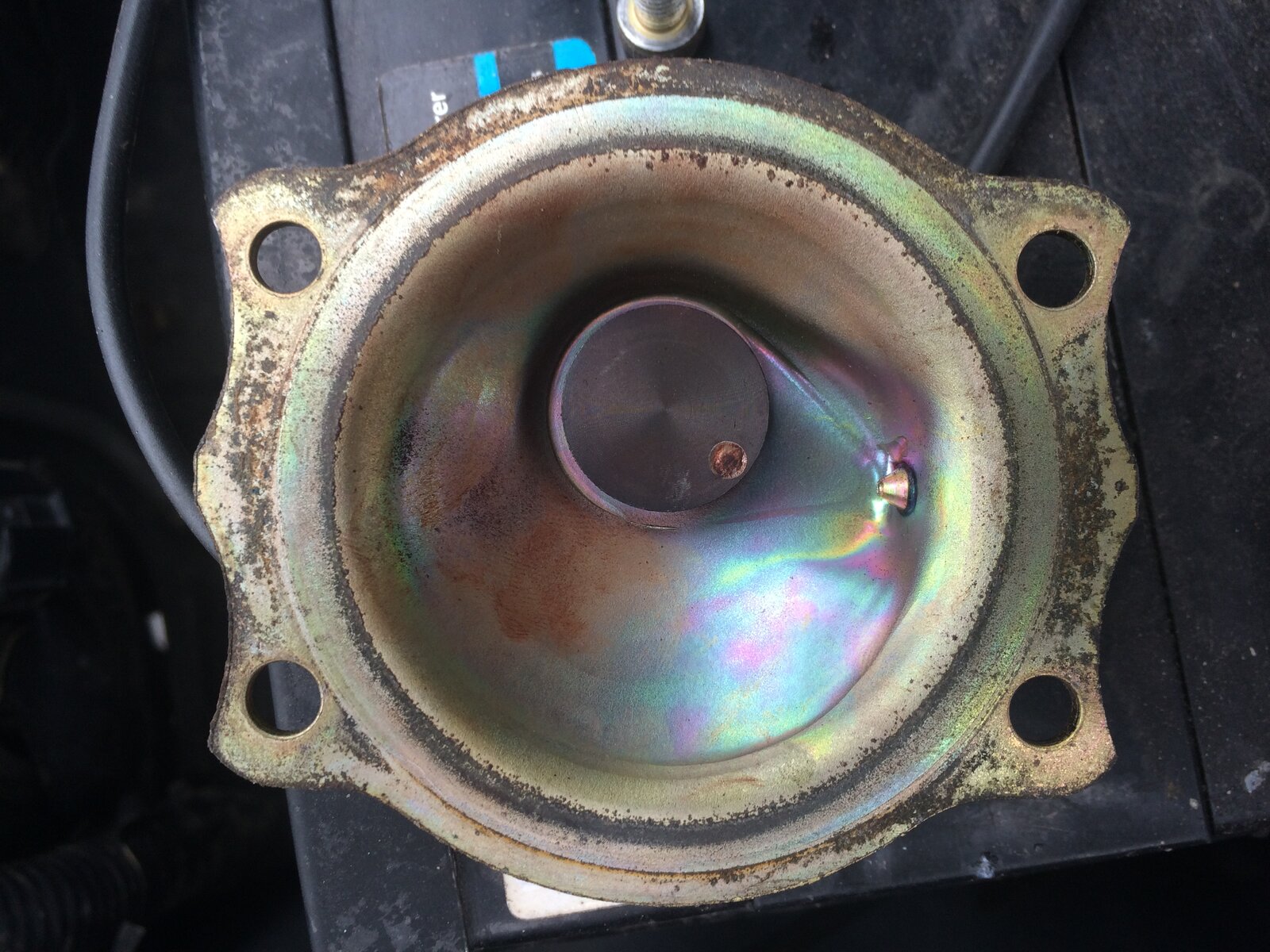

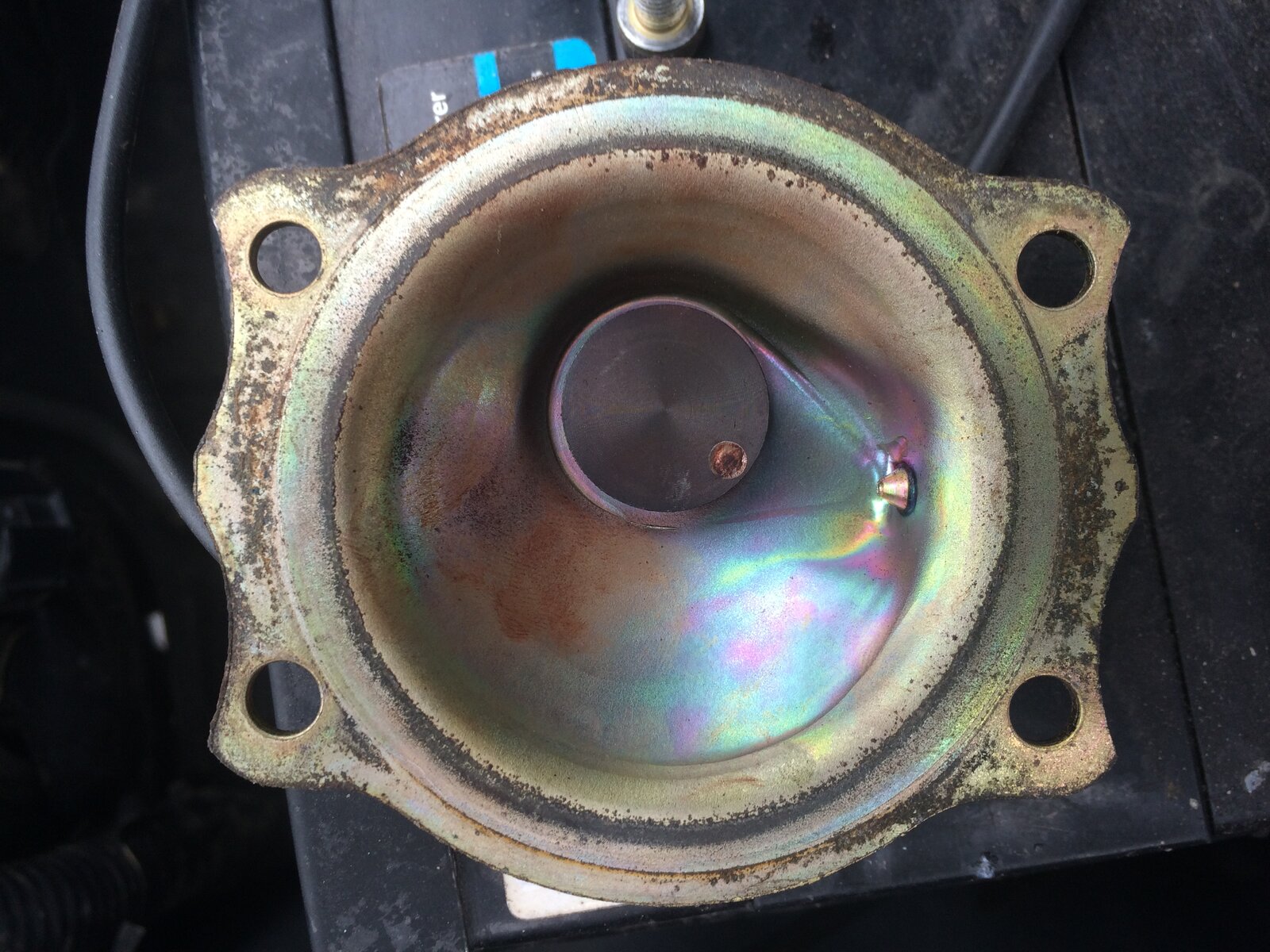

then i removed the 4 allen bolts on top of the pump

on the other side of this plate you can see the profile of the max off boost adjuster mine has a wear mark on it so i can set it back to standard easily to increase the fuel move the thicker part to the middle to lower spring tension and to decrease fuel move the thinner part to the middle of the plate

under the this plate is the rubber diaphragm and under that is the toothed wheel boost compensator i wound this all the way down and then back one full turn but im not being very scientific about it i just didnt want to have it maxed out

to adjust this wheel like this you have to modify the plunger on the diaphragm you might as well you should still have the grinder out after fixing your allen key it also makes it easy to set the plunger in the right place you want the bit with the widest gap facing the front of the pump i put a little mark on top of the diaphragm and the pump to get the plunger back in i had to stick a screwdriver down the hole where it goes and gently push a spring loaded pin back and release it gently i think is pops out more than it is supposed to when you just pull the plunger off it the i pushed the plunger back down and torn it 180 degrees so my marks lined up

that's it really its just a matter of fine tuning make sure it is warm and drive it up a hill with someone following you and check for black smoke between 1000 and 2000 rpm a little is ok but try not to go mad use common sense you should really fit an exhaust gas temp sensor and i wouldn't think of touching the main fuel adjust screw with the sheath on without one if anyone has anything to add please do and if i have missed anything or got anything wrong please correct me

I have drawn a couple of arrows it is quite hard to take a picture of the screw that needs to be removed to adjust the toothed boost compensator this picture is from the back of the pump and the top arrow is the max off boost adjustment and the bottom arrow is the screw you need to remove to get to the boost compensator it has a vacuum pipe on the end of it

after fiddling round a little i did it a different way you only need a 13mm spanner, 5mm allen key, a long flat blade screw driver and an angle grinder the first thing i did was adjust my allen key

then i removed the 4 allen bolts on top of the pump

on the other side of this plate you can see the profile of the max off boost adjuster mine has a wear mark on it so i can set it back to standard easily to increase the fuel move the thicker part to the middle to lower spring tension and to decrease fuel move the thinner part to the middle of the plate

under the this plate is the rubber diaphragm and under that is the toothed wheel boost compensator i wound this all the way down and then back one full turn but im not being very scientific about it i just didnt want to have it maxed out

to adjust this wheel like this you have to modify the plunger on the diaphragm you might as well you should still have the grinder out after fixing your allen key it also makes it easy to set the plunger in the right place you want the bit with the widest gap facing the front of the pump i put a little mark on top of the diaphragm and the pump to get the plunger back in i had to stick a screwdriver down the hole where it goes and gently push a spring loaded pin back and release it gently i think is pops out more than it is supposed to when you just pull the plunger off it the i pushed the plunger back down and torn it 180 degrees so my marks lined up

that's it really its just a matter of fine tuning make sure it is warm and drive it up a hill with someone following you and check for black smoke between 1000 and 2000 rpm a little is ok but try not to go mad use common sense you should really fit an exhaust gas temp sensor and i wouldn't think of touching the main fuel adjust screw with the sheath on without one if anyone has anything to add please do and if i have missed anything or got anything wrong please correct me

Attachments

Last edited: