Just by way of update, I've done about 10000 miles on the Whiteline bushes now and can't speak highly enough of them for on and off road use.

Otherwise, back on page 6, I covered the interior build. We had three big drawers in the back, the fridge, wardrobe area fixed in place of the back seats with space for 4 wolf boxes and a 55 litre water tank.

Having lived with it for 3 trips now totalling about 5 months of everyday use, we felt it was great, did everything we wanted but was too rigid. So, since getting back from our slow 3 month trip down to Greece, I've been busy changing a few things.

First job was to reduce the size of the drawers as we found that a there was a lot of free vertical space in each drawer meaning they could be shallower. So I trimmed them up a bit.....

Reducing the height allowed the unit to be moved more rearwards which released enough space to re-fit the rear seats and keep the drawers fitted if necessary.

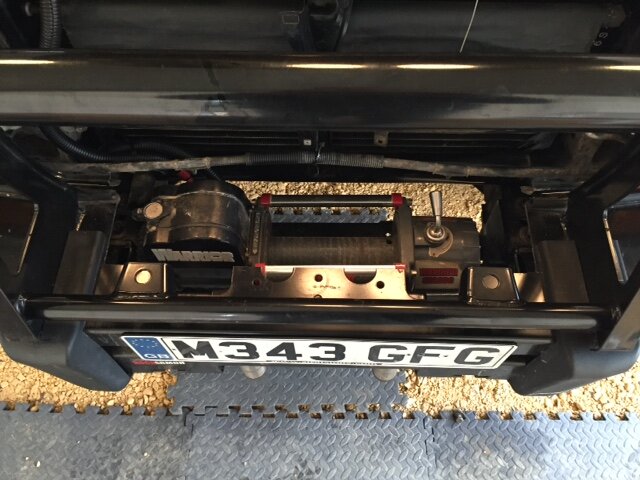

Previously, the battery and T-Max pump occupied space where the rear seats were and because I wanted to keep them while having rear seats fitted if necessary, I found a new home for them behind the fridge. They fitted with about 5mm to spare.

I extended the switch on the pump moving it to the switch/fuse panel on the rear n/s inner wing. The air line is now permanently connected and lives in a compartment with a chequer plate door under the new electric box......

The electric box contains the investor, the solar panel controller, CTEK charger and shore hook up. The 240v supply is connected directly to the fridge and optionally to the charger to keep that topped up if lights etc are getting used a lot. It's also a storage area for electrical bits we carry......

With our previous set up, it was not possible to put the seats back and flat and stay in the car if the weather was really bad. So the new design simply put a box around the tank, pump and filler/breather and a small platform (on which we can put dogs). There is also stuff space under the platform and in the box. The lid of the box holds 2 wolf boxes and there are stops glued to the surface to prevent the boxes moving. If there are no dogs, the boxes will also fit on the platform. 2 or 4 wolf boxes will similarly fit on top the drawers as will a 2nd spare wheel that I will be taking to the Western Sahara in October.

Most of the time, the boxes will live on top of the drawers as we have Gecko chairs and a camp table which will get strapped in here.

Final fitting up with all the gear will be this week, so will post some more pics then. Then, on to a service ready for the Sahara.