@YardPig I'm going to post some picture of master seal as you request, in next post.

First let me say; I've never had a leak at master to deal with on a 100 series. What I have dealt with on the Master Assembly of the 100 series is corrosion of control wire that connects between ABS to pump motor, dead booster motor and failed ABS unit. That is in order of issue that I see most often.

When I use to work on GM, Ford, Chrysler, etc. I was rebuilding master cylinder often. They would leak at plunger seals. We could see this fairly easily by looking in foot well around master or something in engine bay on firewall just below master.

I just don't see this on Series 100. I'm not saying the seals of plunger don't fail. Just that I've not had to deal with. IMHO the number one reason the plunger seal failure may be related to brake fluid. Either not flushing fluid as often enough or adding "wrong or bad" fluid that's damaging to components. Toyota did have a recall (2005-07 IIRC) for master seals, but

not on the 100 series. It seems the issue was with adding non Toyota fluid causing seals to fail. My money was on the rubber that was used. As any DOT I, II or III should have worked just fine, but didn't.

Keep in mind we are only talking about master assembly herein this thread. But be aware, the parts down stream like caliper piston seal, flexible & hard lines we're seeing fail more and more with age. Inspection is key!

I'll state what I feel is obvious as to which leaks/failed seals in the 100 series need addressing. But first I'll restate something that was just posted in the "Brake failure thread". It is

the one part that will fail and with little to no warning, no matter how well we maintain or inspect. It

will cause brake failure or at least until all but bottom of peddle travel and then very little braking.

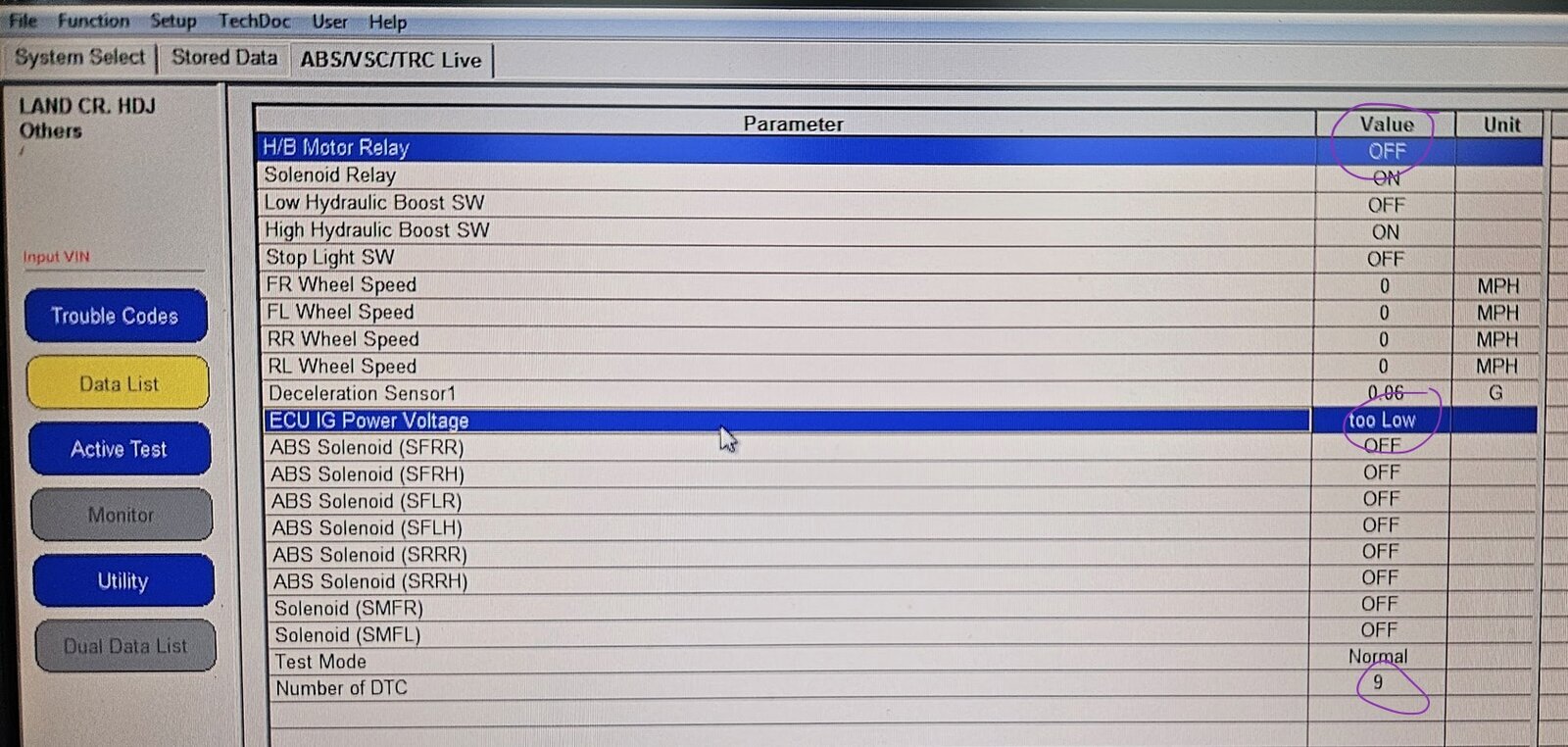

This is the Booster motor. The motor has brush that wear out. Interestingly I've found commutator worn-out (dead spots) and bushes still have enough material to last for hundreds if not thousands of hours. I'm seeing this failures around 250K miles. BUT Miles aren't the key to motor life, it's hours of motor run time. City stop and go drive using brakes often vs all HWY miles is obviously going to have motor run more and so failing at lower miles. Other issues can cause motor to run often such as moisture in fluid, air in system (fluid), leak(s), weak accumulator. It's also possible for the ABS to not delivery current to the motor or the resistance wire to go bad. But I'm just seeing motors bad. In any case, if that motor fails, booster pressure is not regained with use and peddle will go to the floor.

I've been replacing motor and cleaning up wires for those that are on a tight budget. But really the best is to just go ahead and replace the accumulator assembly with new in our aging fleet. I found

www.partsouq.com has the best deal at $800. It includes motor, pump, accumulator and wire.

Accumulator assembly circled in black

Here is wire corrosion I find in about 30% of all rigs I've inspected. Why...it may be related to overfilling reservoir more than anything else.

Last edited: Jan 25, 2019

Master thread, with index to many helpful links.

2007 LC Restore & off road build (Merlot)

Scored 2007 LC W/63K No AHC .. Pre sold/Sold

2007 LX Restore and modified S.A.I test vehicle. (GrayGal) Scored a VVT w/all known issue in the VVT.

2003 LX Restore (Sky) Scored 03LX, w/busted FDS.

Reactions:

AllLC and Ayune

[IMG alt="2001LC"]https://forum.ih8mud.com/data/avatars/m/28/28583.jpg?1707759065[/IMG]

SILVER Star

Joined Nov 4, 2007 Threads 194 Messages 13,350 Location

Colorado

As per your request I'll state what I feel is obvious as to which leaks/failed seals.

The plunger has multiple seals on it (see picture above in post # 231) It's the only seals in master assemble that get fiction with every press on the peddle. Weak seals here could be very hard to detect and yield the soft peddle feel of first pump of peddle. Not only reason for first pump soft peddle issue, just one in the system. It could also allow pressure drop (forward seals on plunger) which kicks on booster motor often, without any loss of fluid leak. Rear seals of plunger failure could yield a leak resulting in loss of fluid.

Reservoir grommet leaks can yield loss of fluid but will not affect brakes per-say, unless fluid gets below minimum. Although fluid may get into boot of wire attracting moisture and may corridor wire and connection.

The O-ring of pressure senor seal should be replace if removed. A leak here would be fairly easy to see.

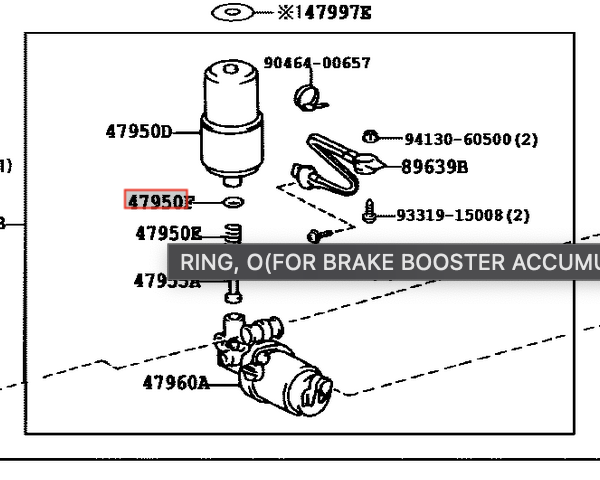

The pump to accumulator seal (o-ring) would be replaced if removed. A leak here would be fairly easy to see and make it difficult for pump to build pressure in accumulator.

This gasket is not available to my knowledge, it's between booster motor and pump. This appears to just be a moisture and dirt seal. But take care to not damage if separating pump and motor.

Last edited: Jan 25, 2019