stuzbot

Well-Known Member

- Joined

- Jan 20, 2021

- Messages

- 500

Righty oh. Finally having vanquished the ABS Sensor From Hell [coming to a cinema near you], I've finally pulled my rear stub axle and got to have a look at the seals. So, what do those of you who've "been there— done that" think of these?

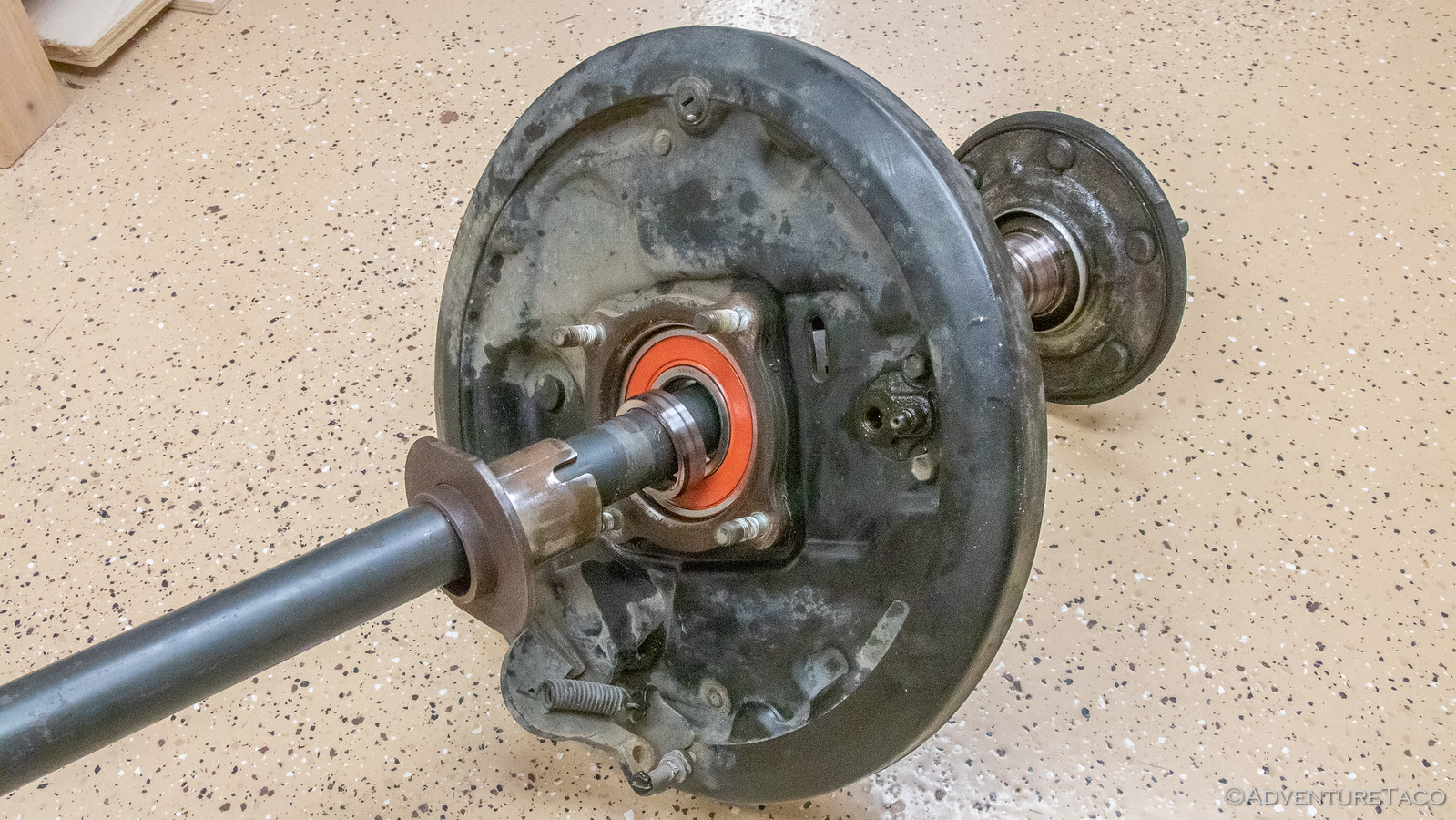

To my untrained eye, the inner oil seal looks fine. There's no obvious deformation or tears to the rubber...

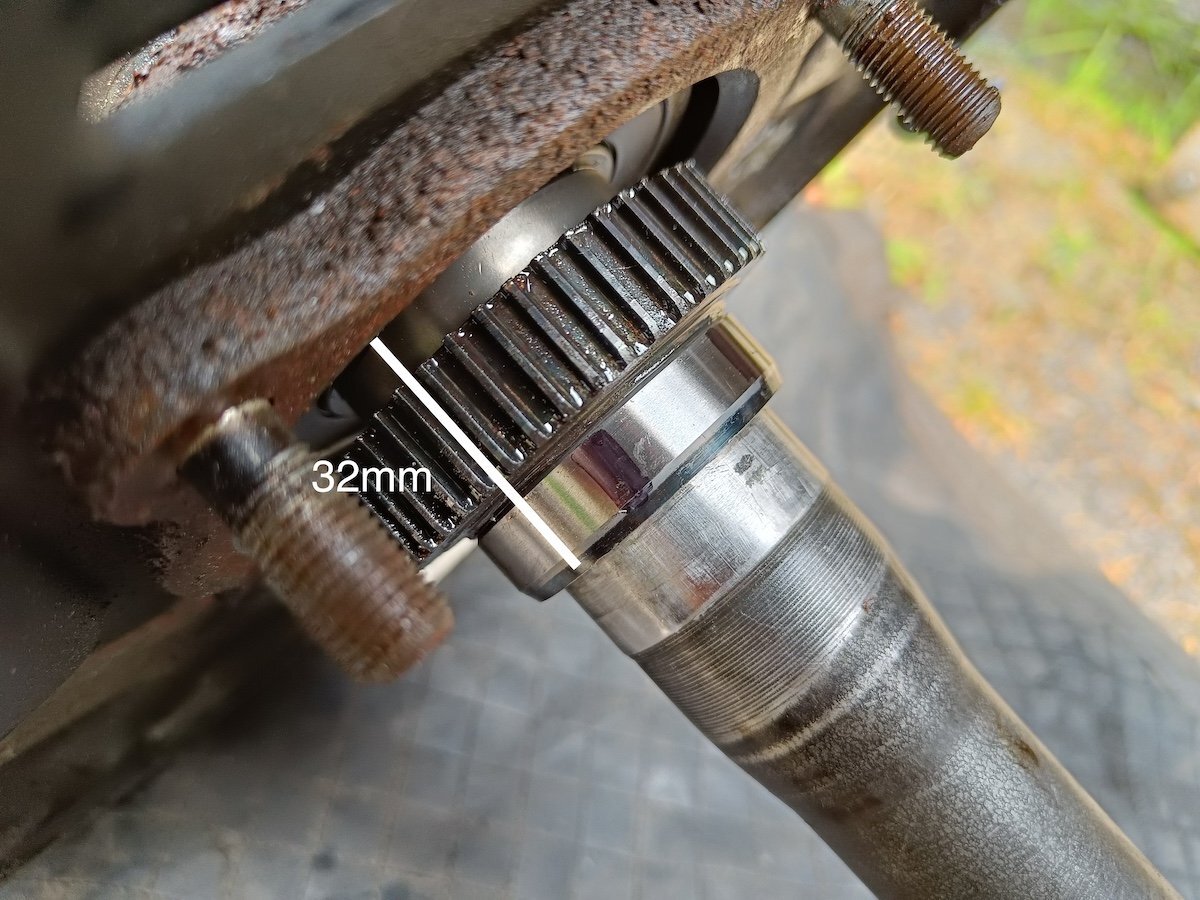

...which is more than I can say for the outer seal. As you can see from the photos, the ridged seam around its centre is running at an angle and looks "rippled" in places. I'm assuming it's not meant to look like that...

Of course, as I've mentioned before, the truck came with a spare inner oil seal when I bought it and so it looked like previous owner intended to replace that. Before starting to tear things down and, in spite of my natural pessimism, I had hoped the dampness round the rear hub might be a leaking wheel cylinder [easy job] but expected it to turn out to be that inner oil seal [medium job]. But it's now looking like it's an outer oil seal [arse of a job].

When taking the nuts off the back of the hub assembly, I found that one of them was pretty rough turning, like it had been cross-threaded before. Also, on that side of the wagon, the brake backing plate has been replaced with a new one. So I'm starting to think that someone took it apart to fit the new backing plate and somehow knackered the outer oil seal, while sticking things back together again. And either they or someone else has seen the leak, bought an inner oil seal to fix it and then done what I've just done; pulled things apart, realised it's the outer oil seal and decided to give up, at that point.

So what think you all?

BTW I do have a hydraulic press. So "in theory" should be able to press the bearing etc off the axle. But "in theory" the ABS Sensor just lifts out after you undo the bolt. So I'm not even going there yet.

To my untrained eye, the inner oil seal looks fine. There's no obvious deformation or tears to the rubber...

...which is more than I can say for the outer seal. As you can see from the photos, the ridged seam around its centre is running at an angle and looks "rippled" in places. I'm assuming it's not meant to look like that...

Of course, as I've mentioned before, the truck came with a spare inner oil seal when I bought it and so it looked like previous owner intended to replace that. Before starting to tear things down and, in spite of my natural pessimism, I had hoped the dampness round the rear hub might be a leaking wheel cylinder [easy job] but expected it to turn out to be that inner oil seal [medium job]. But it's now looking like it's an outer oil seal [arse of a job].

When taking the nuts off the back of the hub assembly, I found that one of them was pretty rough turning, like it had been cross-threaded before. Also, on that side of the wagon, the brake backing plate has been replaced with a new one. So I'm starting to think that someone took it apart to fit the new backing plate and somehow knackered the outer oil seal, while sticking things back together again. And either they or someone else has seen the leak, bought an inner oil seal to fix it and then done what I've just done; pulled things apart, realised it's the outer oil seal and decided to give up, at that point.

So what think you all?

BTW I do have a hydraulic press. So "in theory" should be able to press the bearing etc off the axle. But "in theory" the ABS Sensor just lifts out after you undo the bolt. So I'm not even going there yet.