Allchin

Active Member

- Joined

- Nov 16, 2010

- Messages

- 67

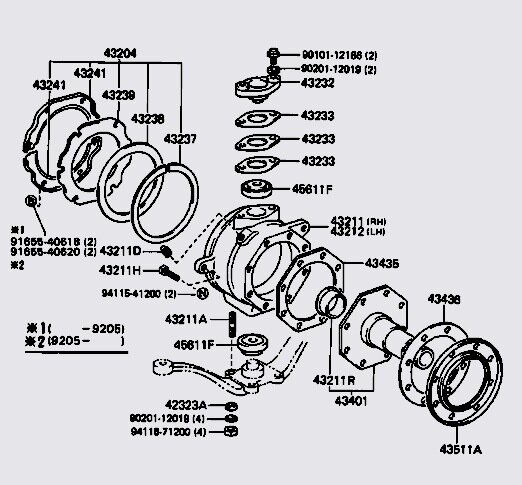

Does anyone know what is the best way to follow the FWM instructions when changing the swivel bearing, without using the special tool for centering the swivel housing by using the top and bottom shims, or does everyone adjust the preload by the top shim only, after all the centre may only be 10thou or so out. But that might be why members find Milners oil seal doesnt last long as it cannot cope as well as the OME.

Stephen

Stephen