- Joined

- Mar 7, 2010

- Messages

- 2,414

- Country Flag

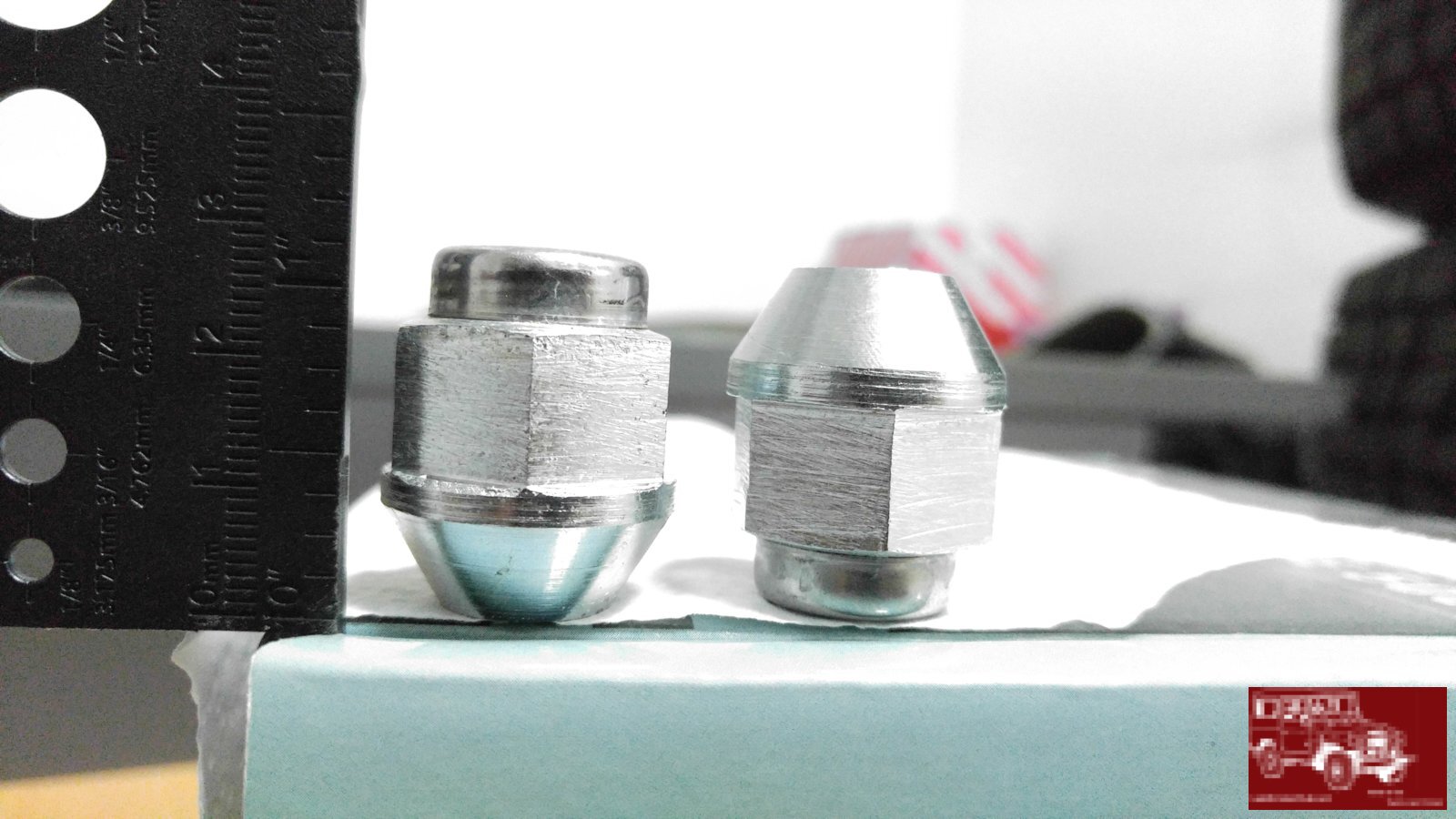

I got a set of wheels that I wanted to put on, but I don't have the nuts. I checked at a tyre place, and they gave me something that looks like they are made for steel rims. Are they the right nuts (see pic), or should they be the more common type for alu-rims, with both a conical tip and a flat collar ?

The nuts I have for other, more standard, oem rims I have (16" and 17"), are all the same type and too big to fit in the holes of these rims.

The rims have Toyota part number PZ406-70670-ZC, but are made by Ronal in Germany.

The second question is what to do with the spare wheel hoist? Since the center hole in these rim is much smaller than the standard rims have, the crossbar that hooks into the wheel doesn't fit. Have you seen these rims elsewhere, and what does the spare wheel hoist hook look like?

The nuts I have for other, more standard, oem rims I have (16" and 17"), are all the same type and too big to fit in the holes of these rims.

The rims have Toyota part number PZ406-70670-ZC, but are made by Ronal in Germany.

The second question is what to do with the spare wheel hoist? Since the center hole in these rim is much smaller than the standard rims have, the crossbar that hooks into the wheel doesn't fit. Have you seen these rims elsewhere, and what does the spare wheel hoist hook look like?