- Joined

- Feb 14, 2021

- Messages

- 568

- Country Flag

Centre diff lock rebuild:

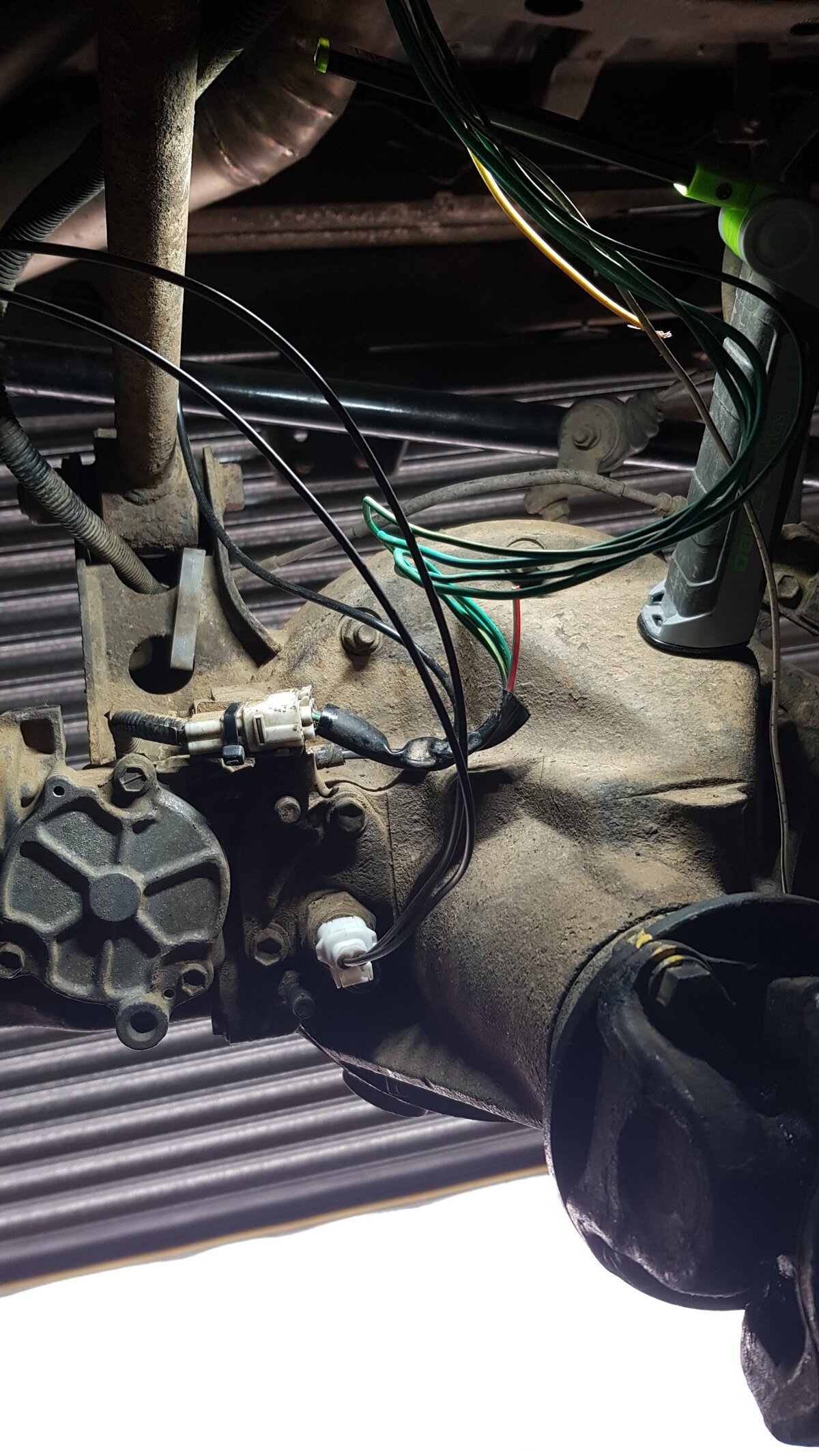

Lowered the GB cross member to give me space to undo the 4 bolts holding the actuator on to the transfer case.

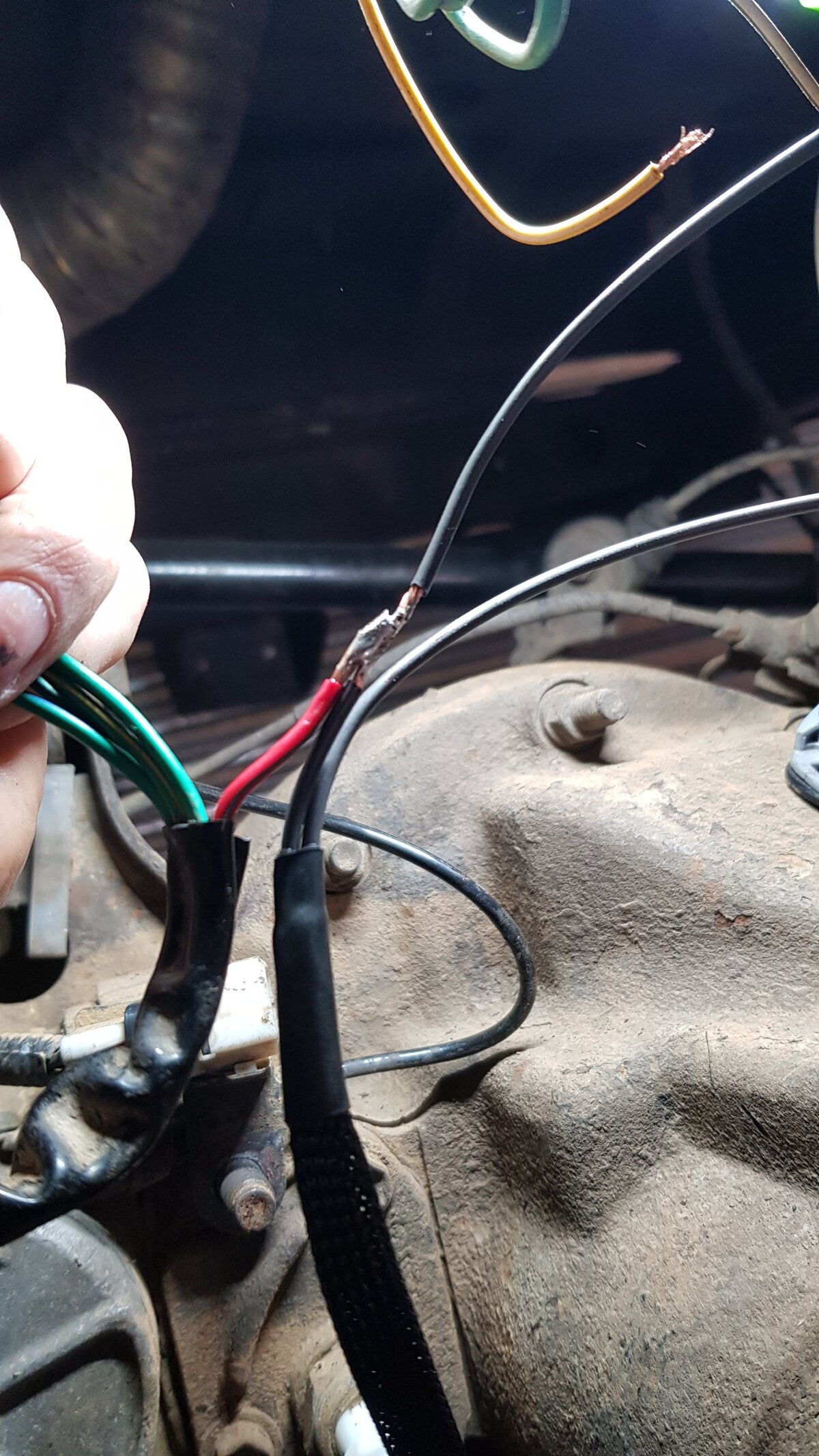

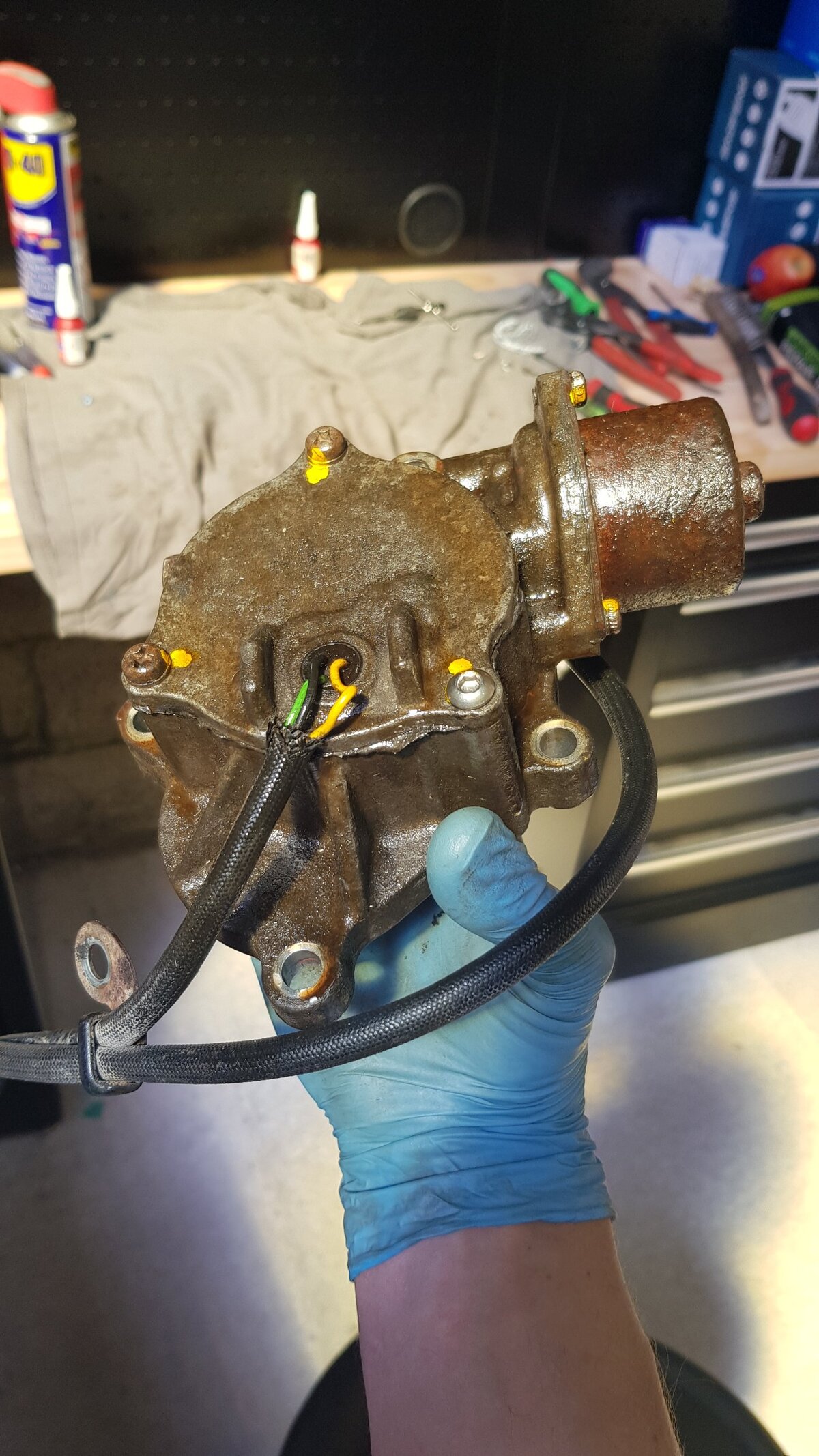

From the outside it didnt look too bad, once I finally got it open and all apart it looked like something dredged up from the Titanic. A lot of corrosion and the motor had got a bit hot by the looks of things. 3 of the magnets were detached too.

If new ones were available I probably would have bought a new one as I didnt hold much hope it would work again. Any way, I pressed on, cleaning corrosion off and coating with some grease or WD40. Glued the magnets back on. Being careful to keep them in their original orientation and order.

During removal of the actuator lid, part of the lid broke away on the inside as it was so corroded together. Luckily it was just the part that held the O ring. There wasnt much left of the rubber any more.

Once it was all cleaned up it didnt look too bad, all the parts that were supposed to move now did so smoothly again.

I checked continuity of the position switches on the plate and they were all working fine.

Dry assembled it and bench tested it with a battery, the motor worked and spun the actuator gear round a treat!

I checked it all worked on the car and it did!!

Took it all apart and reassembled it with some sealant to keep the moisture out, gave it a spritz on the outside with some AV30 to help keep the corrosion down and refitted.

Quick test around the yard, engaging and dis engaging the actuator, it all worked perfectly! Well happy with that!

Lowered the GB cross member to give me space to undo the 4 bolts holding the actuator on to the transfer case.

From the outside it didnt look too bad, once I finally got it open and all apart it looked like something dredged up from the Titanic. A lot of corrosion and the motor had got a bit hot by the looks of things. 3 of the magnets were detached too.

If new ones were available I probably would have bought a new one as I didnt hold much hope it would work again. Any way, I pressed on, cleaning corrosion off and coating with some grease or WD40. Glued the magnets back on. Being careful to keep them in their original orientation and order.

During removal of the actuator lid, part of the lid broke away on the inside as it was so corroded together. Luckily it was just the part that held the O ring. There wasnt much left of the rubber any more.

Once it was all cleaned up it didnt look too bad, all the parts that were supposed to move now did so smoothly again.

I checked continuity of the position switches on the plate and they were all working fine.

Dry assembled it and bench tested it with a battery, the motor worked and spun the actuator gear round a treat!

I checked it all worked on the car and it did!!

Took it all apart and reassembled it with some sealant to keep the moisture out, gave it a spritz on the outside with some AV30 to help keep the corrosion down and refitted.

Quick test around the yard, engaging and dis engaging the actuator, it all worked perfectly! Well happy with that!

Attachments

-

20250515_162636.jpg393.4 KB · Views: 20

20250515_162636.jpg393.4 KB · Views: 20 -

20250516_111123.jpg540.6 KB · Views: 15

20250516_111123.jpg540.6 KB · Views: 15 -

20250515_174959.jpg350.1 KB · Views: 17

20250515_174959.jpg350.1 KB · Views: 17 -

20250515_161724.jpg650.9 KB · Views: 18

20250515_161724.jpg650.9 KB · Views: 18 -

20250516_093153.jpg636.7 KB · Views: 16

20250516_093153.jpg636.7 KB · Views: 16 -

20250515_162632.jpg611.2 KB · Views: 14

20250515_162632.jpg611.2 KB · Views: 14 -

20250516_100833.jpg716.9 KB · Views: 13

20250516_100833.jpg716.9 KB · Views: 13 -

20250515_171113.jpg439.4 KB · Views: 14

20250515_171113.jpg439.4 KB · Views: 14 -

IMG-20250515-WA0026.jpeg621.5 KB · Views: 15

IMG-20250515-WA0026.jpeg621.5 KB · Views: 15 -

IMG-20250516-WA0002.jpeg580.1 KB · Views: 18

IMG-20250516-WA0002.jpeg580.1 KB · Views: 18