- Joined

- Feb 14, 2021

- Messages

- 628

- Country Flag

Hi All,

Following on from my intro here New 80 series owner - [Leaving Land Cruiser Club]

I will be keeping a thread going for the works and adventures I hope to have with my new 80 series.

Not long after I bought it I took it to Overland Cruisers to have a thorough once over. My logic being that I am more than capable of finding faults with a vehicle, but being new to Land Cruisers and not wanting to waste time breaking down or waiting for something to break that could have been spotted earlier by a more experienced eye. The main issues were leaking radiator, front hub seals, brake and clutch fluids, plus cambelt, plus some diff naff and triv.

I will try to do a fair amount of work myself, since it non of it looks especially complicated. Nothing major has been started yet with it because I am waiting for a load of parts to arrive so I can get stuck in. First main job will be a refresh of the cooling system, the radiator is pretty haggard, and is most likely the original. I already have a replacement, but am waiting for top and bottom hoses, thermostat and rad cap to arrive before I start with that job.

Before I go any further, everyone loves pictures, and if you haven't seen teem from the intro here are a few.....

A smaller item that was picked up was that the front and rear diff locks were not working. Had a bit of a play about with them and did some reading.

Turning the rotary dial, I can hear, I guess, a relay clicking while in rear lock position, but no noise from the actuator itself. The front one is making a noise, but not been able to check if It is actually engaging with the diff. Rear position switch, on the diff wasn't working for a start, plus one of the wires to the plug on the front one was broken..... so ordered a new set. Beck Arnley make switches that seem to be a common replacement. Not sure how much a genuine one is, but way more than £12 I guess.

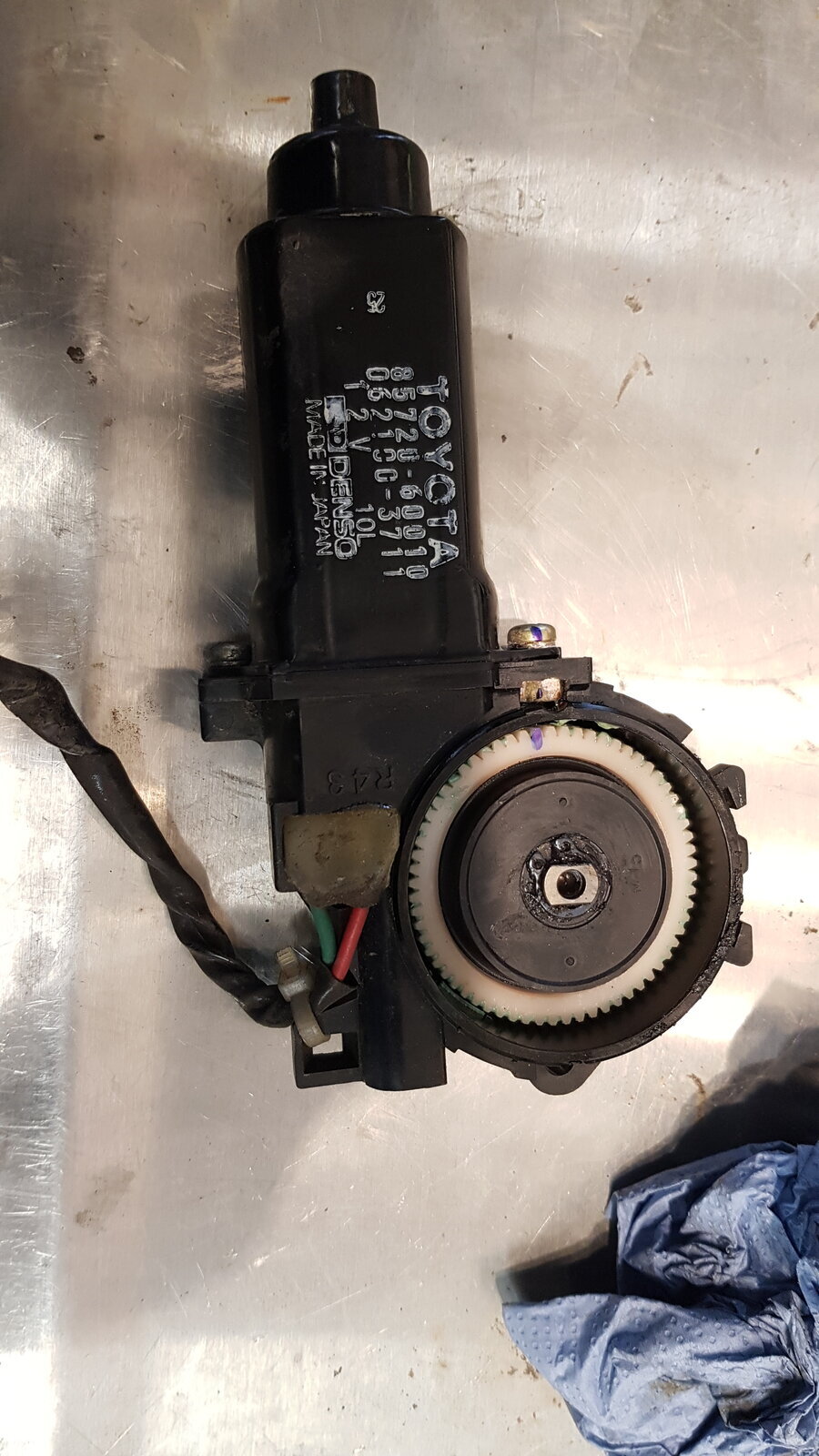

Fitted both the switches, obviously that didn't make the actuators work, can't be that simple! Took the rear actuator out to investigate a bit more....

Once the shield was off, it looked like some one had been in here before me....Any way carried on and took the switch plate and actuator out

First problem was a common once from what I have read, and that is the magnets de-bonding from the housing, weirdly one of them was cracked in half too. Im hoping that once it is all glued back together it will still work. Does any one know if it will affect its magnetism?? I was a bit confused at first thinking there was a magnet missing, but its just because they had all moved around the housing to one side.

Second issue was the actuator rod is seized into thee housing, I have left it soaking in wd40 over night, I was able to get a tiny bit of movement out of it using a soft faced hammer so have hopes its salvageable.....

Following on from my intro here New 80 series owner - [Leaving Land Cruiser Club]

I will be keeping a thread going for the works and adventures I hope to have with my new 80 series.

Not long after I bought it I took it to Overland Cruisers to have a thorough once over. My logic being that I am more than capable of finding faults with a vehicle, but being new to Land Cruisers and not wanting to waste time breaking down or waiting for something to break that could have been spotted earlier by a more experienced eye. The main issues were leaking radiator, front hub seals, brake and clutch fluids, plus cambelt, plus some diff naff and triv.

I will try to do a fair amount of work myself, since it non of it looks especially complicated. Nothing major has been started yet with it because I am waiting for a load of parts to arrive so I can get stuck in. First main job will be a refresh of the cooling system, the radiator is pretty haggard, and is most likely the original. I already have a replacement, but am waiting for top and bottom hoses, thermostat and rad cap to arrive before I start with that job.

Before I go any further, everyone loves pictures, and if you haven't seen teem from the intro here are a few.....

A smaller item that was picked up was that the front and rear diff locks were not working. Had a bit of a play about with them and did some reading.

Turning the rotary dial, I can hear, I guess, a relay clicking while in rear lock position, but no noise from the actuator itself. The front one is making a noise, but not been able to check if It is actually engaging with the diff. Rear position switch, on the diff wasn't working for a start, plus one of the wires to the plug on the front one was broken..... so ordered a new set. Beck Arnley make switches that seem to be a common replacement. Not sure how much a genuine one is, but way more than £12 I guess.

Fitted both the switches, obviously that didn't make the actuators work, can't be that simple! Took the rear actuator out to investigate a bit more....

Once the shield was off, it looked like some one had been in here before me....Any way carried on and took the switch plate and actuator out

First problem was a common once from what I have read, and that is the magnets de-bonding from the housing, weirdly one of them was cracked in half too. Im hoping that once it is all glued back together it will still work. Does any one know if it will affect its magnetism?? I was a bit confused at first thinking there was a magnet missing, but its just because they had all moved around the housing to one side.

Second issue was the actuator rod is seized into thee housing, I have left it soaking in wd40 over night, I was able to get a tiny bit of movement out of it using a soft faced hammer so have hopes its salvageable.....