3" exhaust

Woke up this morning feeling fine, had a 3" stainless exhaust on my mind!

So I went back to demon tweeks to invest in some shiny pipework! I stopped off at my mate Chris's garage who does my Mot's. I mentioned and described the system I wanted to do and then told him of the new mod's to the truck (as he knows it well). He looked at me and said "its cool but if its too loud can't pass it"

So after thinking about previous long runs in the truck a too loud exhaust is very tiresome. So I have bought a 5" case high flow re packable silencer. Couldn't justify buying it in stainless as it was 50% more! Tut

The tight 90deg stainless bends are a handy bit of kit to get out of the engine bay.

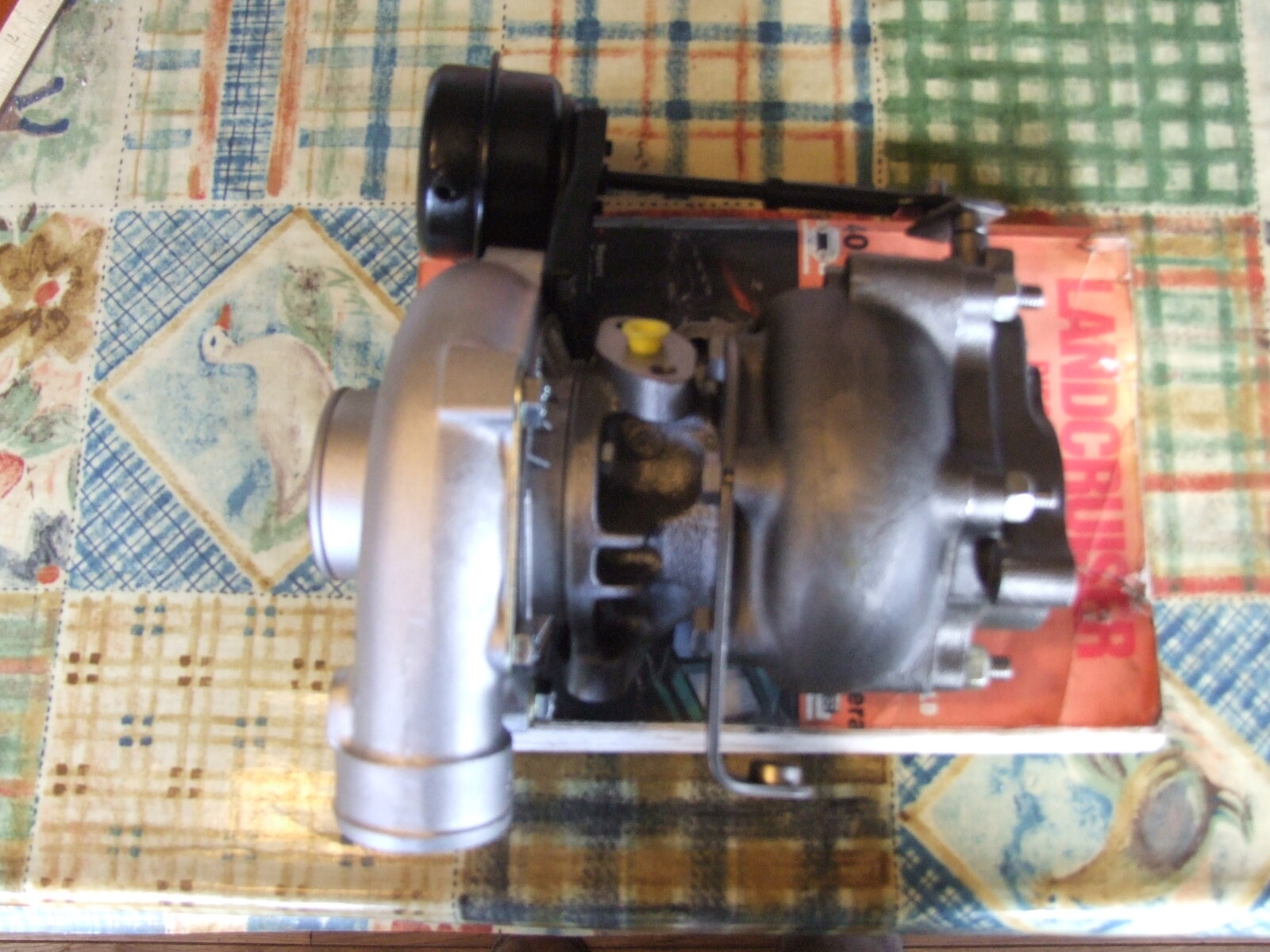

The manifold mod has worked a treat to gain space and will have great flow. You can see the amount of effort that it has taken to get this result. Have tee'd in a turbo boost gauge, the EGT sender, the vacume reroute of the of the 4wd system, the manifold mod in its prime and how well the tight 90 deg 3" exhaust start helps.

After grinding in the flange adapter, its a good fit and can also weld most of the inner edge.

If you want to do a conversion like this, get yourself a demon tweeks catalogue, it has pretty much all the stuff you need to do this job. Or even to make your own stainless exhaust system.

Working out well both pipe ends are parallel, pleasing!

Looks far from standard from this view. Needs more cutting out of the inner wheel arch and treating the cut edge. Needs new shocks all round (were on it when I got it). Even looks like its had the front brake caliper upgrade that someone on the forum posted! Lol

Very happy with the setup looks good to me. There's a couple of issues that need addressing - need to try to make a 10mm flare on the junction from the tight 90 to the downpipe and weld with 100% argon and stainless wire. The others as they are mild steel to stainless can be welded with normal mig (correct?). Need to add some kind of heat shield above the exhaust and to cut a ballini cut on the end!

The previous pic reminds me of when I made a stainless system for my 1st lj70 that I did a 1kzt conversion to back in 2010. Great powerfull machine

)

Just to add a pic of my £400 60 investment. A great basis to make a unique truck. I love it!

I wouldnt modify a mint 60 just to let you know. I made this truck!