- Joined

- Feb 24, 2010

- Messages

- 6,132

- Country Flag

Not being able to tinker (or fix) on the 150 has me bored. I've long wanted the heated screen washer gadget but refused to pay the silly money for the Power shot. This got me thinking - how to make an electric one cheaply.

You need a source of heat: £5.00 on ebay and two glow plugs from a pug arrive on my doorstep.

We need something to hold the heat: £2something from ebay and a 25x50x100 aluminium billet arrives on my doorstep.

We need something to control the heat: £4something and 20 thermostats arrive home Hong Kong

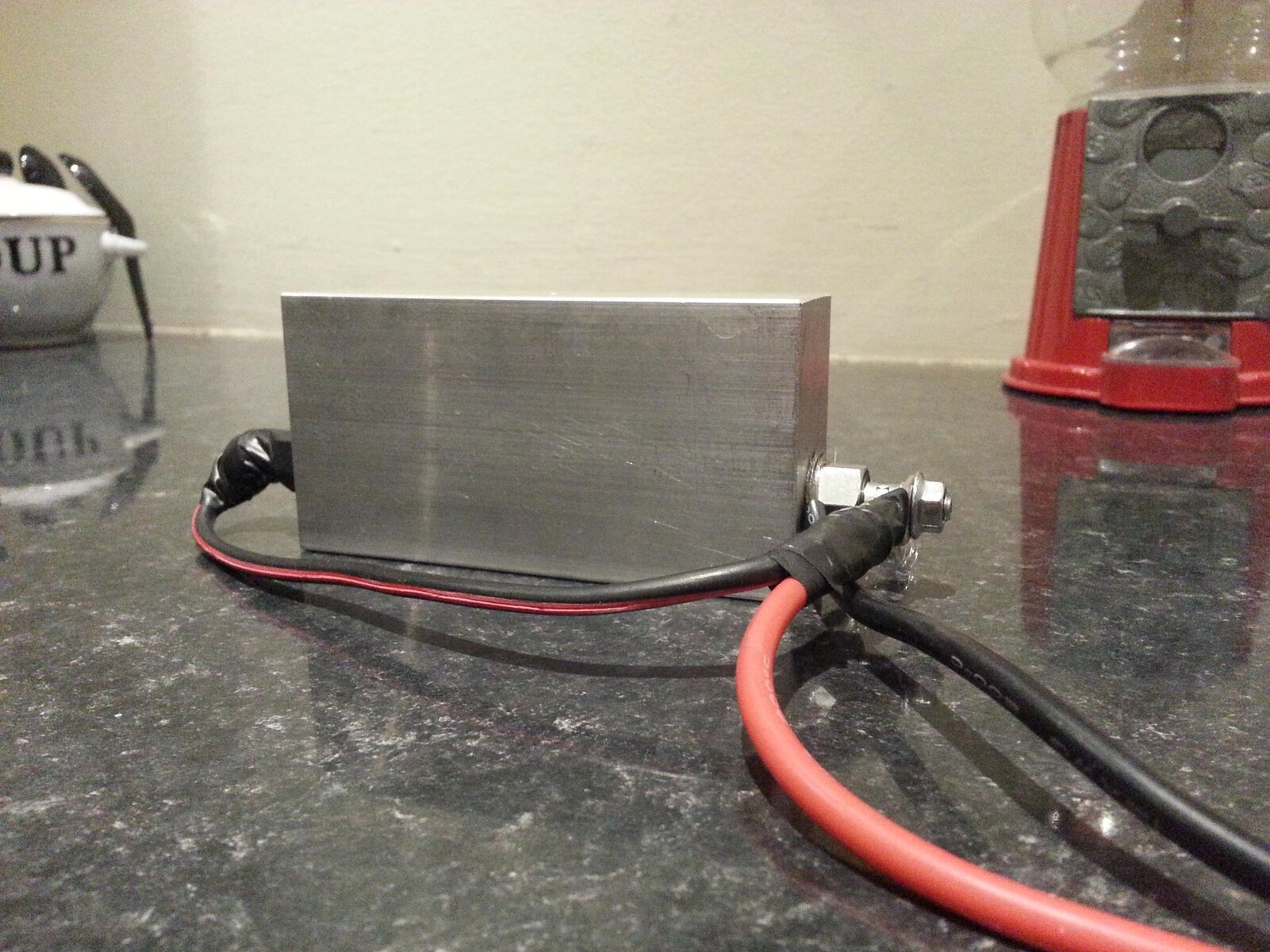

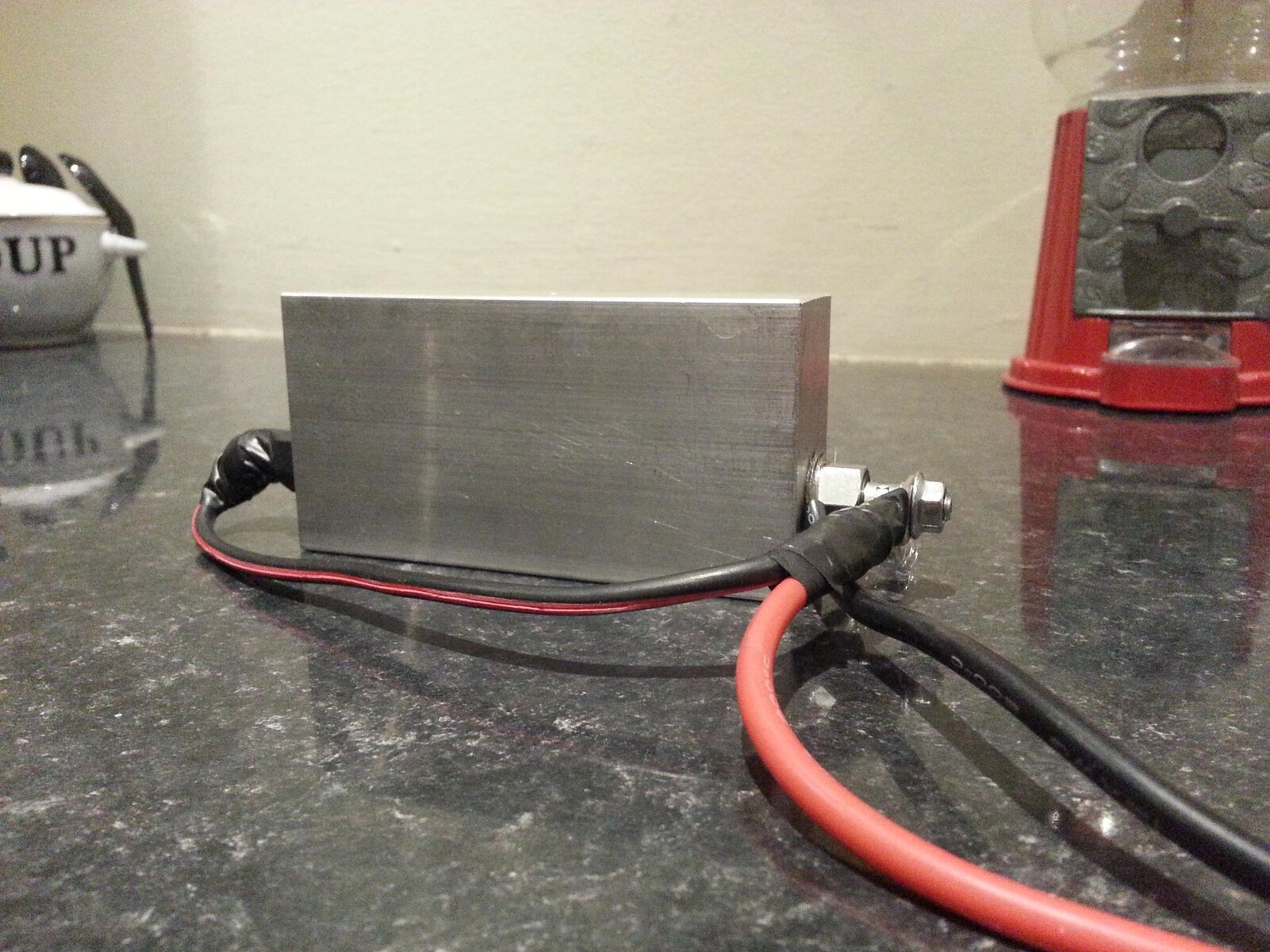

Part-finished product:

With the help of Tony, his drill press, tap set and a shed which would cause an Eskimo to say "FFS it's cold in here", we knocked together the start. (Thanks BTW!)

The two glow plugs are tip to tip. We drilled all the holes as small as possible to minimise the gap between the glow plug and the ali block. While there are parts that are touching, there are air gaps. I was thinking of heating the block (a lot) putting in a drop of molten lead in them and quickly screwing the glowplug back in.

I still need to drill the main channel through the block which will be a ±12mm hole, tap both ends and put a threaded hose barb in.

Another idea I had is to drill two 6-8mm channels next to each other and use it in a U-turn way. I prefer option one as it gives you a small reservoir of hot water.

Electrically, the thermostat switches off at 45c and will drive a relay to turn the glowplugs on and off.

Does it work? Well, the block of ali was left outside and cooled to 9c. Turn it on and it reached 20 degrees in about 10 seconds. Plenty to melt the frost on the window. About a minute later it was 45c.

In under two minutes it was 70c and my desk started to smell like hot paint.

Another, maybe simpler, cheaper option would be a round ali bar, plugs at each end and copper tube wrapped around it.

Assuming you have a set of taps, you could knock this together for £10-15. I've not seen inside the power shot but guess it's not much different?

The longevity of the glow plugs might be a problem but at £2.50 each, 30 seconds to swap one, it's not the end of the world.

Instead of a relay to turn them on and off, you could drive them with something cleverer and ease their life.

I'll be getting the rest of the bits this week and should finish it - will update.

You need a source of heat: £5.00 on ebay and two glow plugs from a pug arrive on my doorstep.

We need something to hold the heat: £2something from ebay and a 25x50x100 aluminium billet arrives on my doorstep.

We need something to control the heat: £4something and 20 thermostats arrive home Hong Kong

Part-finished product:

With the help of Tony, his drill press, tap set and a shed which would cause an Eskimo to say "FFS it's cold in here", we knocked together the start. (Thanks BTW!)

The two glow plugs are tip to tip. We drilled all the holes as small as possible to minimise the gap between the glow plug and the ali block. While there are parts that are touching, there are air gaps. I was thinking of heating the block (a lot) putting in a drop of molten lead in them and quickly screwing the glowplug back in.

I still need to drill the main channel through the block which will be a ±12mm hole, tap both ends and put a threaded hose barb in.

Another idea I had is to drill two 6-8mm channels next to each other and use it in a U-turn way. I prefer option one as it gives you a small reservoir of hot water.

Electrically, the thermostat switches off at 45c and will drive a relay to turn the glowplugs on and off.

Does it work? Well, the block of ali was left outside and cooled to 9c. Turn it on and it reached 20 degrees in about 10 seconds. Plenty to melt the frost on the window. About a minute later it was 45c.

In under two minutes it was 70c and my desk started to smell like hot paint.

Another, maybe simpler, cheaper option would be a round ali bar, plugs at each end and copper tube wrapped around it.

Assuming you have a set of taps, you could knock this together for £10-15. I've not seen inside the power shot but guess it's not much different?

The longevity of the glow plugs might be a problem but at £2.50 each, 30 seconds to swap one, it's not the end of the world.

Instead of a relay to turn them on and off, you could drive them with something cleverer and ease their life.

I'll be getting the rest of the bits this week and should finish it - will update.

Last edited by a moderator: