Would someone with access to to manual of some kind be kind enough to look up a couple of torque settings for me

Just can’t lay my hands on mine since the move and divorce

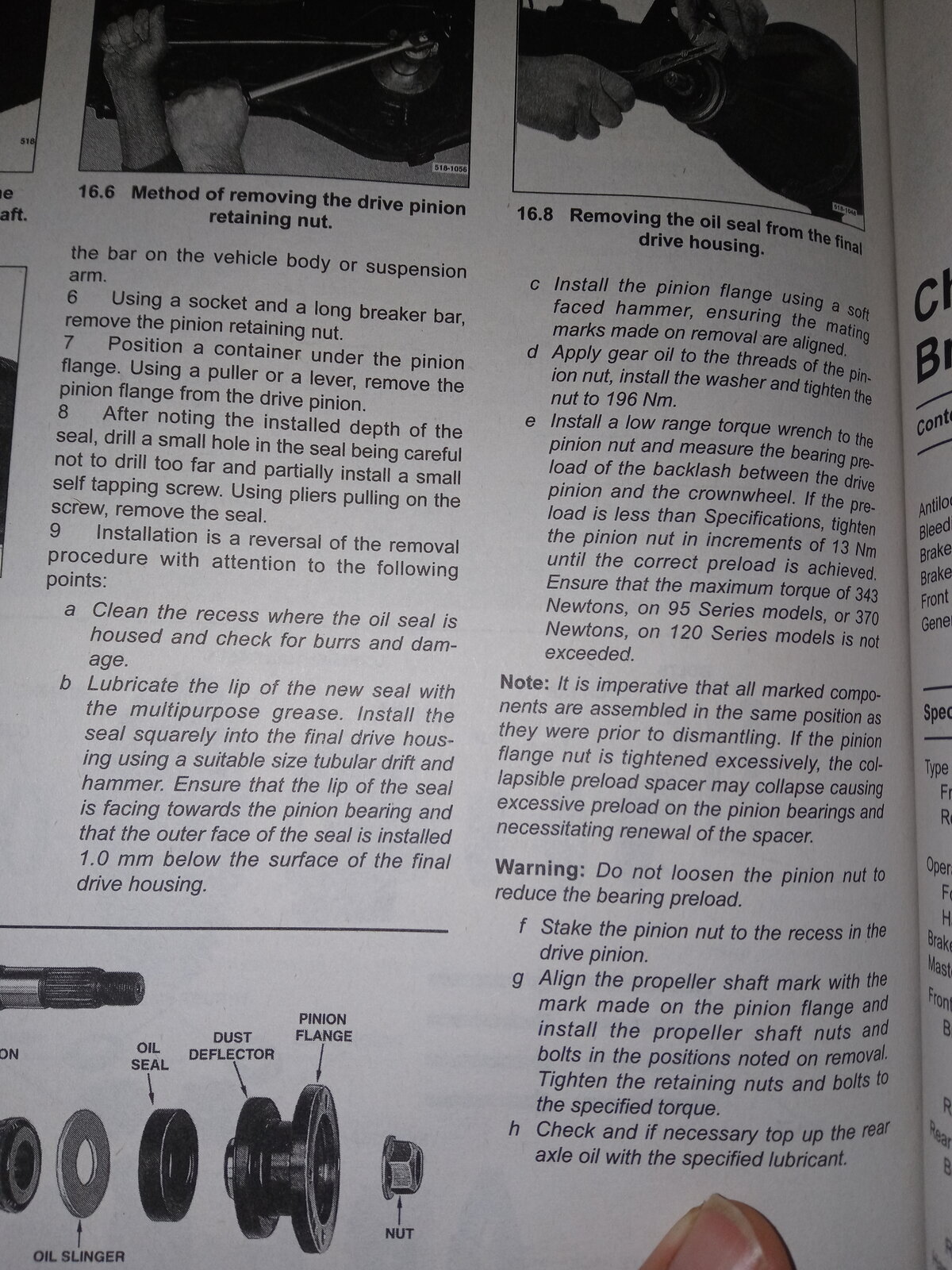

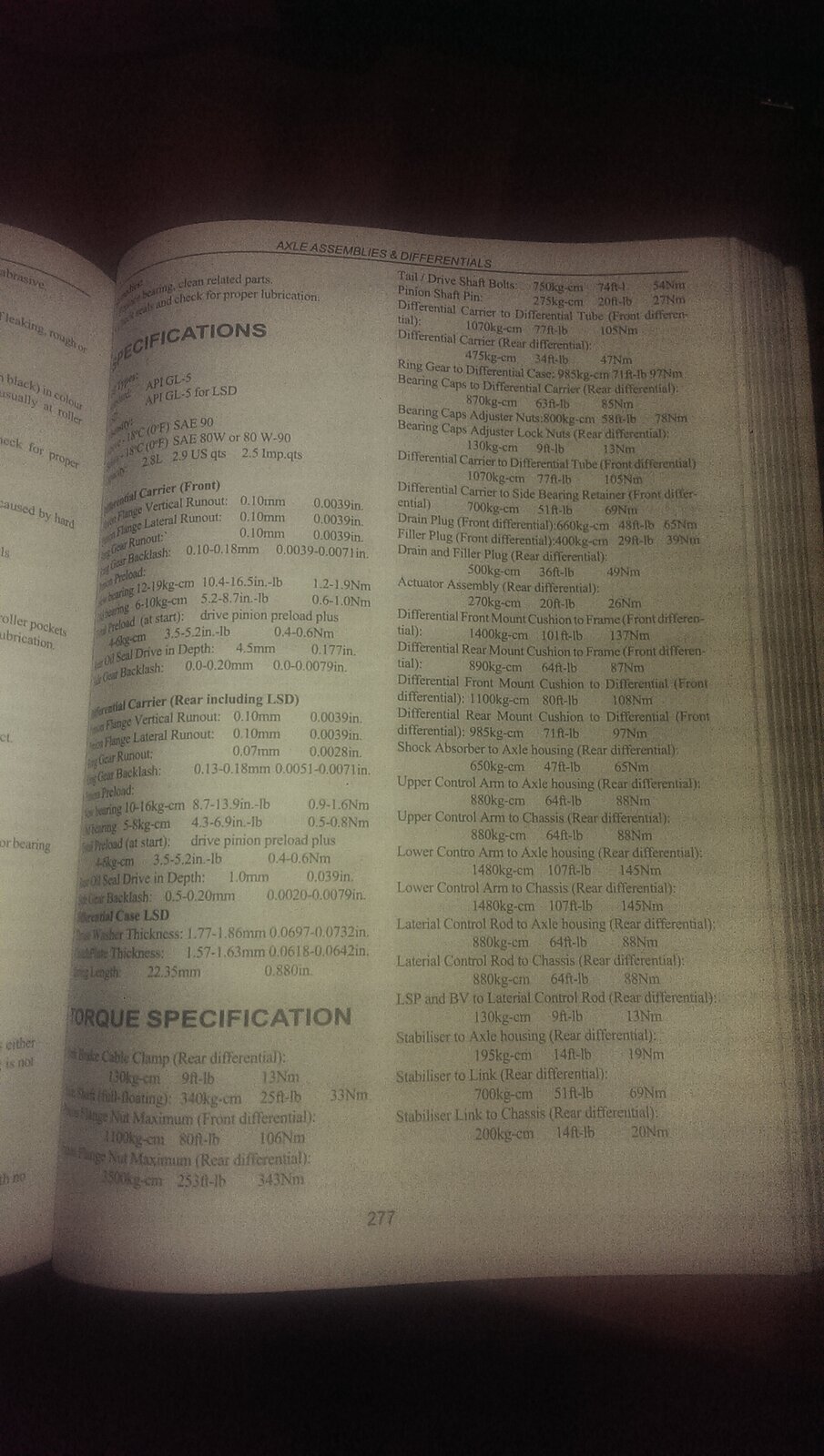

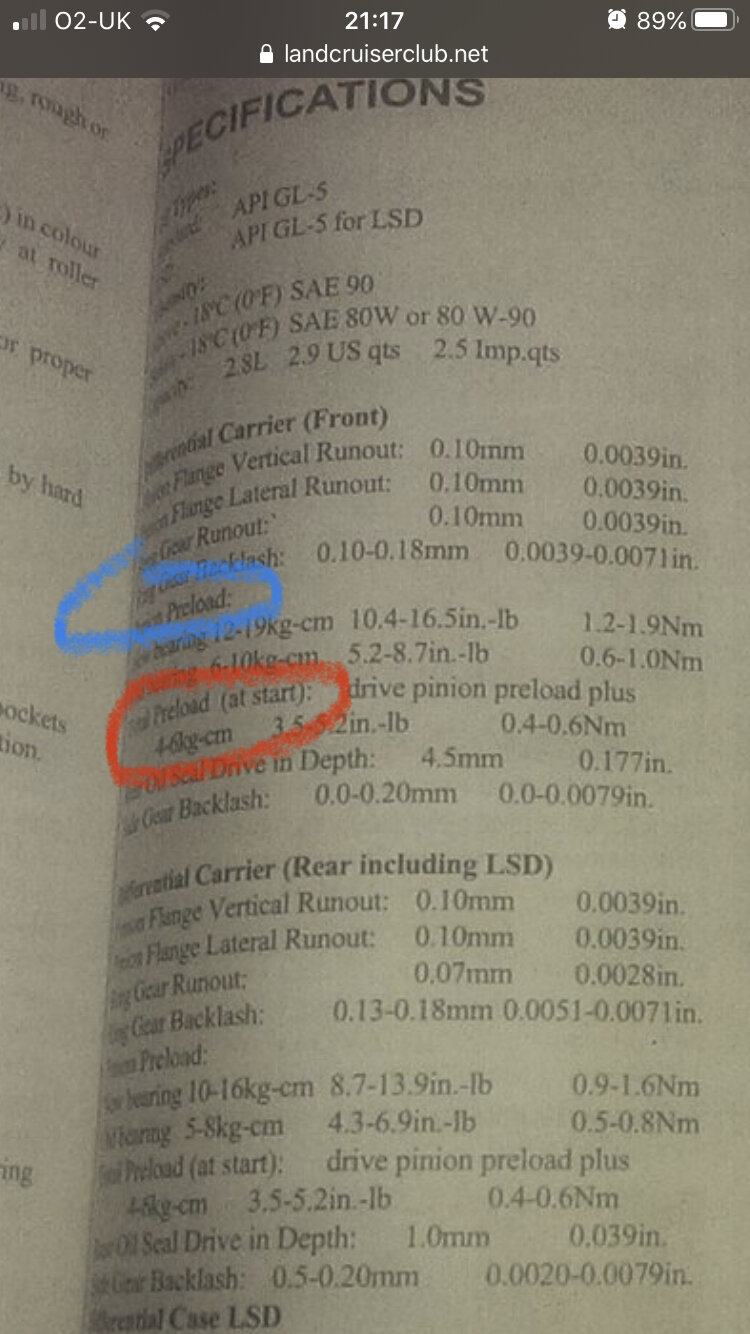

Transfer box output flange nut?

Rear axle input flange nut?

Thank you

Just can’t lay my hands on mine since the move and divorce

Transfer box output flange nut?

Rear axle input flange nut?

Thank you