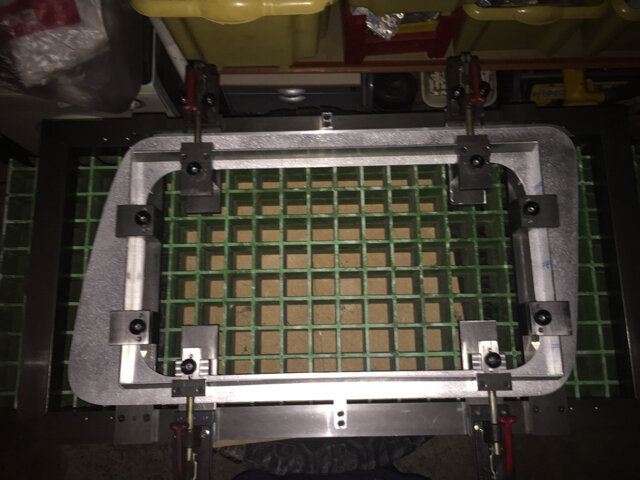

…and I'm told they will be working on the welding jig next week. [emoji4][emoji4][emoji4]

Dare I book space on the sleigh for delivery…?

Dare I book space on the sleigh for delivery…?

Last edited:

Also you never know who he might have helping him these days. Could get damaged by ramming in the chimney too tight, that sort of thing.

Yep! I think two struts would be good.I'm considering doing an optional additional gas strut. The single struts I have sourced are fine for opening and holding the door on its own but I see sometimes items can be hung from the door as extra storage.

The option would be in two parts. An additional top bracket welded to the door at manufacture with the supply of the mounting grille and additional gas strut as an optional extra. The grille would fix to the gas strut brackets on the door and the rear mounting screws of the latches giving 4 fixing points. Perhaps even source some straps to tie stuff to them if I'm feeling adventurous. [emoji4]

As always, feedback appreciated.

Now, where did I put that mince pie?

No more mince pies for you 'till it's finished.

No more mince pies for you 'till it's finished.[emoji20][emoji20]. Owww…

Now now Rich, man up old son.[emoji20][emoji20][emoji20][emoji30]