Dan W

Well-Known Member

Hi, I've done a ickle bit of searching but I think I might need an adult to help me

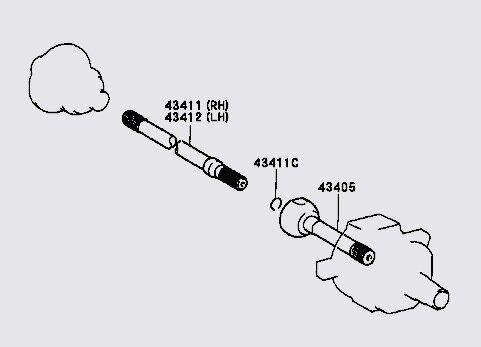

First off, the cv/birfield joints. When I seperate them with my scaffold pole, I've read that a snap ring on the end of the inner shaft will probably break.

From pictures though I can make out that there's two circlip type things on the inner shaft, the outermost one is supposed to be the one that gets broken so I'm going to order two from Toyota tomorrow. However on my EPC it just lists one part number for the snap ring which is 43411C. Is this the outermost one that will need replacing or will I be ordering the inner one that apparently survives the seperation of the birfield?

And secondly I've read that the birfield, knuckle and the trunion bearings need to be packed with moly grease. I've purchased the needle roller bearings to replace the bronze bushes. As they are part of the knuckle should they be packed with moly or wheel bearing grease please (I'm assuming they are packed with grease at all?)?

Thankyou, I'm slightly out of my comfort zone here

First off, the cv/birfield joints. When I seperate them with my scaffold pole, I've read that a snap ring on the end of the inner shaft will probably break.

From pictures though I can make out that there's two circlip type things on the inner shaft, the outermost one is supposed to be the one that gets broken so I'm going to order two from Toyota tomorrow. However on my EPC it just lists one part number for the snap ring which is 43411C. Is this the outermost one that will need replacing or will I be ordering the inner one that apparently survives the seperation of the birfield?

And secondly I've read that the birfield, knuckle and the trunion bearings need to be packed with moly grease. I've purchased the needle roller bearings to replace the bronze bushes. As they are part of the knuckle should they be packed with moly or wheel bearing grease please (I'm assuming they are packed with grease at all?)?

Thankyou, I'm slightly out of my comfort zone here