At last, I have found some time to fit the solar panel and the hi-lift jack. What with all the options for panels and charge controllers, I eventually went for a kit from the sunstore containing a mono crystalline 80w panel, charge controller and all the gubbins needed to fit it. It put ticks in the all the right boxes: power, size, weight, durability and price.

When not in use, it will be stored in the car. As it won't be being used when in motion I decided to put on the lid of the roof box and let gravity and two locating bolts keep it in place. You can just see them in front of the box. You just lift the front edge up and lower it over the bolts to locate it.

i decided to mount the panel on the wall behind the front seats....

It sits on a couple of feet and is secured by door bolts which compress it against rubber pads to stop rattling. All the wiring neatly stores behind the panel itself as there is a 25mm void created by the aluminium surround and the glass being bonded to the front edge. ...

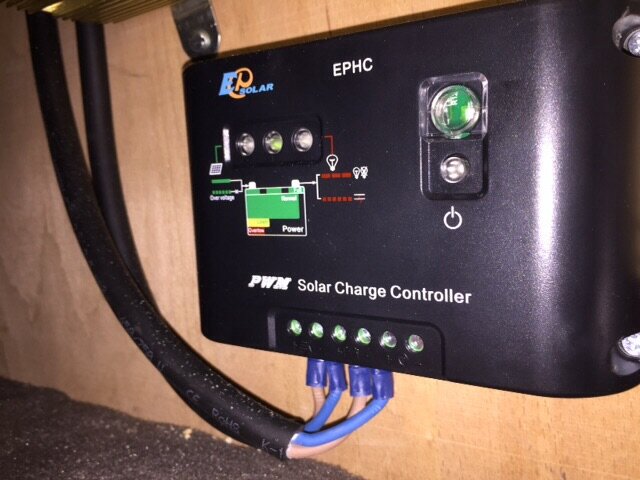

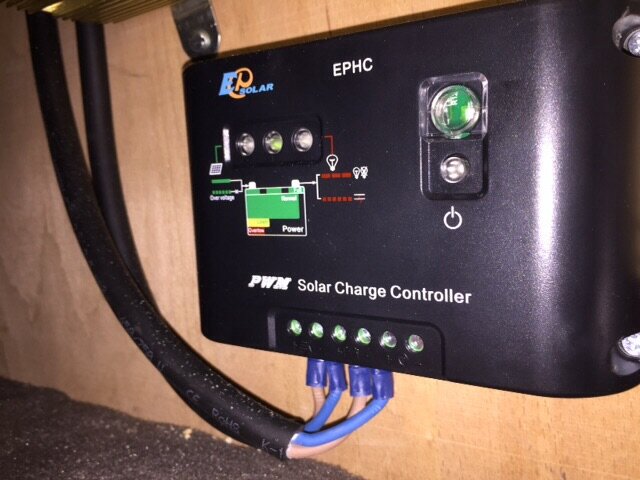

I mounted the the charge controller under the invertor in the cubby hole for the tank, battery, pump etc ......

Its a a nice simple bit of kit which tells you via coloured lights whether it is charging, what level the battery is etc.....

I also chose the same area to mount the hi-lift. It was a bit of a squeeze and I have to take the foot off, but it fits just right ......

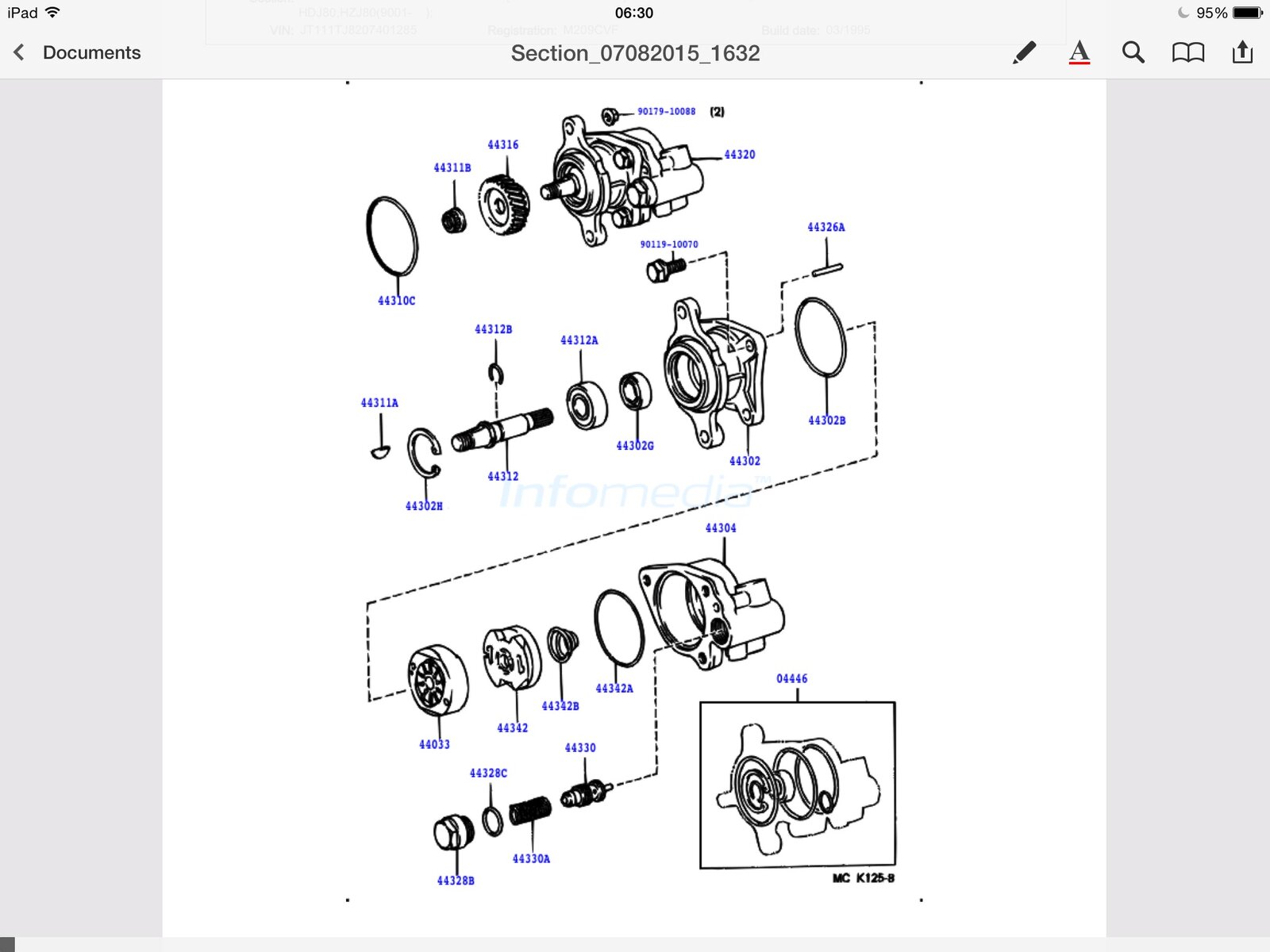

I received the new hub and a few other bits from Toyota the other day so I can rebuild the wheel and put it back on the road.

Still got a long list of jobs to do over the next few weeks to get ready for our slow tour through Southern France, Andorra, Spain and Morocco starting in September for about 12 weeks. We are busy plotting routes but if anyone has any for Spain they would be willing to share, they'd be much appreciated.