Mine both have a smidge of white on one of the flats.

Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tapping noise from front when turning under power

- Thread starter StarCruiser

- Start date

So far, and without yet giving them s clean, both my CVs have slight longitudinal play of around 1mm or so. They don't seem to have any rotational play. The longitudinal could possibly be in the driveshaft to CV spline.

Removed the driveshaft and diff this morning. Yuk. Plastered in grey green goop as was the whole of the inside of the axle. I've now cleaned the diff completely without disassembling it and it looks like there's no wear at all that I can see. However, I do need a bit of help from those that have experienced a good diff and know what to expect. Question is, should there be any play in the gear wheels?

Here's my thoughts, this thing is stone cold at the moment but will get some heat in it during use when everything will expand, and there should be minimal clearances to allow for this (and the oil). Am I wrong? Should it be tight?

Second question, the drive flange bolts were tight as a tight thing on tight day. I couldn't see any evidence of studlock on them. Is it just a case of doing up with spanners, 'up to strip and back one' or is there a torque setting? How do you get in there to torque it if there is? Do they need studlock (asking this as I don't want to add to the difficulty if I ever need to undo them again)?

Cleaned out the cannon balls too. Left them in situ as everything was tight with only a hint of 'dead ahead' and I had changed the ball seals about 10,000 miles ago which were working fine. Got 99.9% of the cv grease out.

Got the internal seals out. I made up my own Heath Robinson puller out of a bit of 12mm studding and some large washers between two nuts at the end. Bit of box section as a slide and a nut and large washer the other end and hey presto, a puller, of sorts which did the job with no damage (apart from my left thumb knuckle but we won't go into that[emoji37]).

Here's my thoughts, this thing is stone cold at the moment but will get some heat in it during use when everything will expand, and there should be minimal clearances to allow for this (and the oil). Am I wrong? Should it be tight?

Second question, the drive flange bolts were tight as a tight thing on tight day. I couldn't see any evidence of studlock on them. Is it just a case of doing up with spanners, 'up to strip and back one' or is there a torque setting? How do you get in there to torque it if there is? Do they need studlock (asking this as I don't want to add to the difficulty if I ever need to undo them again)?

Cleaned out the cannon balls too. Left them in situ as everything was tight with only a hint of 'dead ahead' and I had changed the ball seals about 10,000 miles ago which were working fine. Got 99.9% of the cv grease out.

Got the internal seals out. I made up my own Heath Robinson puller out of a bit of 12mm studding and some large washers between two nuts at the end. Bit of box section as a slide and a nut and large washer the other end and hey presto, a puller, of sorts which did the job with no damage (apart from my left thumb knuckle but we won't go into that[emoji37]).

Well, bit the bullet today and put everything I could ever want including new CVs on an order to Amayama. Window rubbers, drive flanges, seals, power steering pump overhaul kit, needle bearing upgrade, the lot. CVs turned out to have some slight rotational play so decided to just replace and have done. Don't want to do the job again.

Looking forward to not having to pull my windows up. Not looking forward to the import bill.

Looking forward to not having to pull my windows up. Not looking forward to the import bill.

Last edited:

Got my EBC brakes delivered today. [emoji4] Only placed the order yesterday. £250 delivered, standard rotors and yellow stuff pads. Let's hope they work well. If they live up to their claims they should be good.

- Joined

- May 26, 2014

- Messages

- 4,812

- Country Flag

Thats a nice shopping list! Im excited for yer! How much and what does the power steering overhaul kit include?

Don't like the adverts? Click here to remove them

Thanks, looking forward to getting it all.

The seal kit was around £45 from my local Toyota garage but £16.46 from Amayama (plus import plus vat). I believe there is a thread on here about Power steering pump rebuild and I expect the kit has all the seals shown in that, in other words, all the seals and o rings for a complete rebuild.

I'll be able to tell you more when it turns up. About three weeks time I am expecting.

The seal kit was around £45 from my local Toyota garage but £16.46 from Amayama (plus import plus vat). I believe there is a thread on here about Power steering pump rebuild and I expect the kit has all the seals shown in that, in other words, all the seals and o rings for a complete rebuild.

I'll be able to tell you more when it turns up. About three weeks time I am expecting.

Last edited:

- Joined

- May 26, 2014

- Messages

- 4,812

- Country Flag

Cheers. I'll have a search for the thread.

It's in the sticky, but here for ease.

* http://www.landcruiserclub.net/forums/showthread.php/39728-How-to-rebuild-a-power-steering-pump-on-1H-engines"]Power-steering pump rebuild on 1H* engine

* http://www.landcruiserclub.net/forums/showthread.php/39728-How-to-rebuild-a-power-steering-pump-on-1H-engines"]Power-steering pump rebuild on 1H* engine

I've now cleaned off the stub axles and is obvious the bearings have been turning as there's a few thou groove in the bottom part of the shafts. [emoji20] Just trying to find the best route to go but as the pattern parts on the bay are around the £100 mark, I'm virtually decided on getting one of my customers to plasma spray them just as long as this doesn't alter their hardness/temper. Not too keen on LOCTITE (excellent though it is) as the bearings have to move during the setup and when removing so wouldn't want them stuck on the shaft.

Otherwise it's Amayama. Again!

Otherwise it's Amayama. Again!

Last edited:

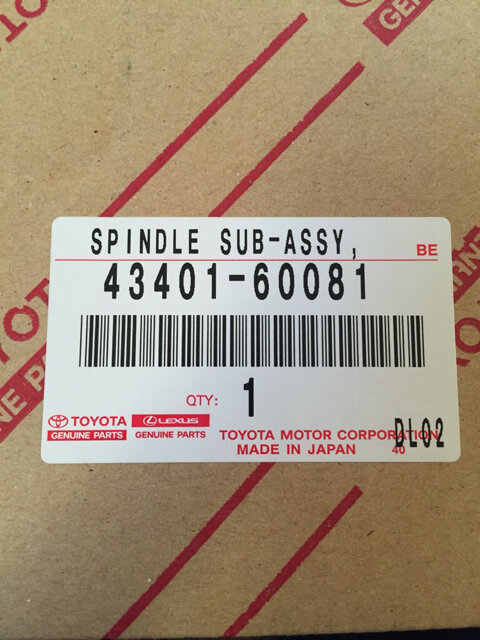

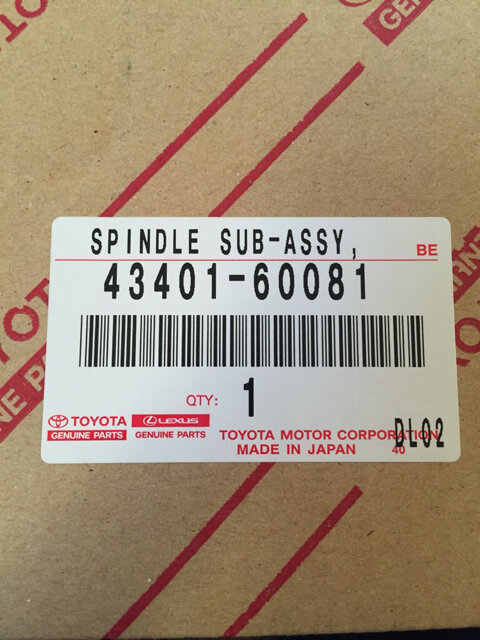

Decision now made. Could metal spray them but the 10 thou groove that would need turning in the outer bearing part of the axle would weaken it. So Amayama it is and at under £70 each, not worth the bother.

Also news on the diff from my pal who has built more diffs, gearboxes and engines for his rally car than I've had hot dinners, is that all the gaps are as they should be, no appreciable wear. [emoji4]

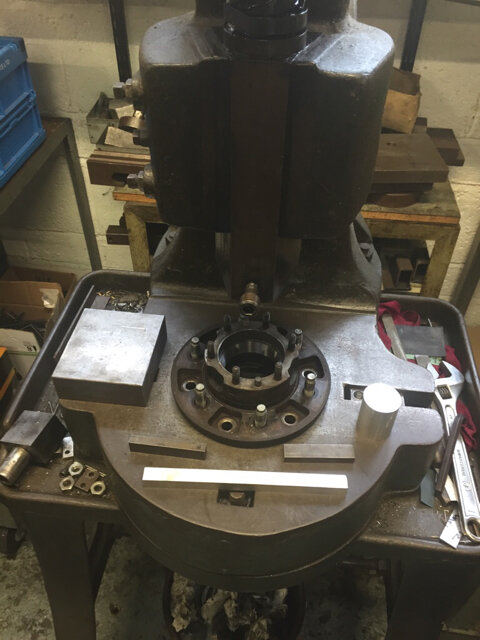

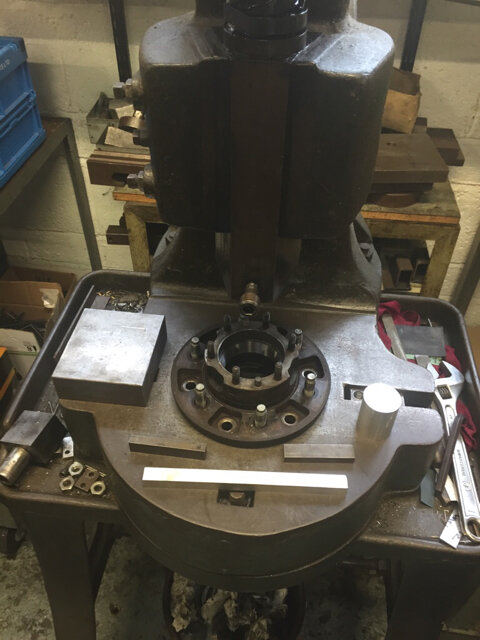

Pressed out all the wheel bearings on Monday. Made up some short lengths of 20x10mm steel to span the bearings in the grooves the nice Mr T has left for the purpose and used an old style fly press to pop them out and back in again with the help of the old bearings and some steel blocks.

Didn't need to cut the old bearings as the smaller just drops back out and the larger was easy to press back out with a piece of ally. All greased up and again used the old bearing to seat the seal nicely.

Access to the fly press made this a nice job by enabling everything to press in and out squarely. Being a hand operated press, it was a joy to use as the feedback of anything sticking where it shouldn't was easy to feel where you don't get this on hydraulic presses so much.

Just a three week wait now. What else can I find to work on…[emoji6][emoji4]

Also news on the diff from my pal who has built more diffs, gearboxes and engines for his rally car than I've had hot dinners, is that all the gaps are as they should be, no appreciable wear. [emoji4]

Pressed out all the wheel bearings on Monday. Made up some short lengths of 20x10mm steel to span the bearings in the grooves the nice Mr T has left for the purpose and used an old style fly press to pop them out and back in again with the help of the old bearings and some steel blocks.

Didn't need to cut the old bearings as the smaller just drops back out and the larger was easy to press back out with a piece of ally. All greased up and again used the old bearing to seat the seal nicely.

Access to the fly press made this a nice job by enabling everything to press in and out squarely. Being a hand operated press, it was a joy to use as the feedback of anything sticking where it shouldn't was easy to feel where you don't get this on hydraulic presses so much.

Just a three week wait now. What else can I find to work on…[emoji6][emoji4]

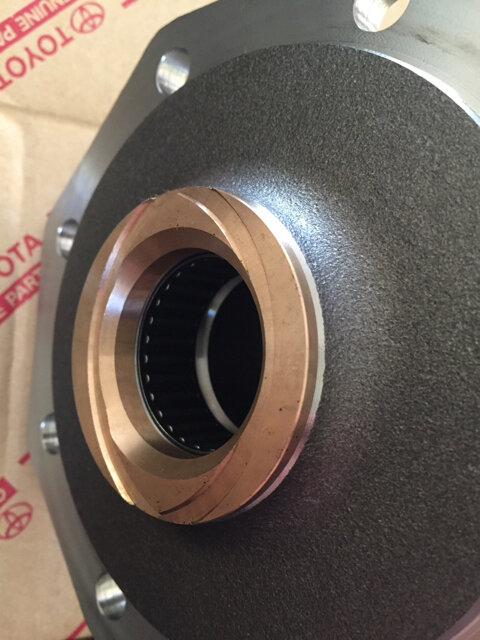

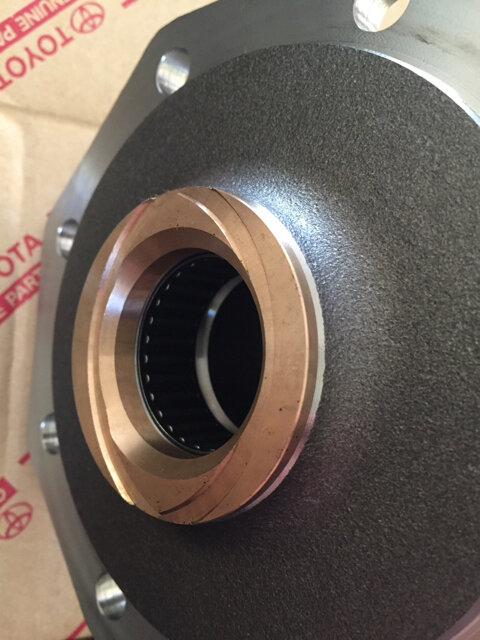

Everything's now here from Japan. Opened up the new updated stub axles and hey presto, they come with the needle roller bearings and shorter bronze bushing already fitted [emoji1].

And a nice chamfer to help seat the shaft seal correctly without tearing it or stopping the hub from seating correctly. Thanks Mr T[emoji4].

So, I have two needle bearings and two short bronze bushes (and two long bronze bushes) if anyone wants them at what I've paid for them. [emoji4]

And a nice chamfer to help seat the shaft seal correctly without tearing it or stopping the hub from seating correctly. Thanks Mr T[emoji4].

So, I have two needle bearings and two short bronze bushes (and two long bronze bushes) if anyone wants them at what I've paid for them. [emoji4]

Ian Chuter

Well-Known Member

- Joined

- Dec 8, 2012

- Messages

- 426

- Country Flag

Result!

PM sent Warren.

And thanks.

And thanks.

Last edited:

Made the most of the weather today and put the front axle back together again. Not much to add to the excellent write ups elsewhere on here and Ih8mud.

Except that I found fitting the half shafts to the well greased Birfield was easier done by aligning the spines up correctly and then letting the shaft's weight plus just a little downward pressure locate the snap ring in the lead-in machined in the Birfield. A little bit of a push on the snap ring with a screwdriver helped and it was then a doddle to tap the shaft in with the big rubber mallet [emoji6].

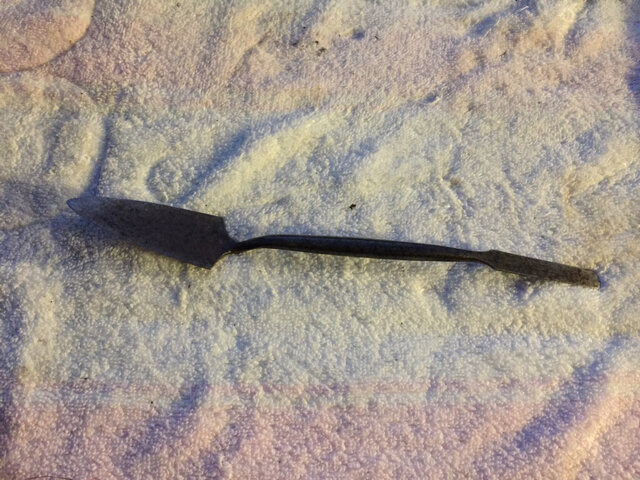

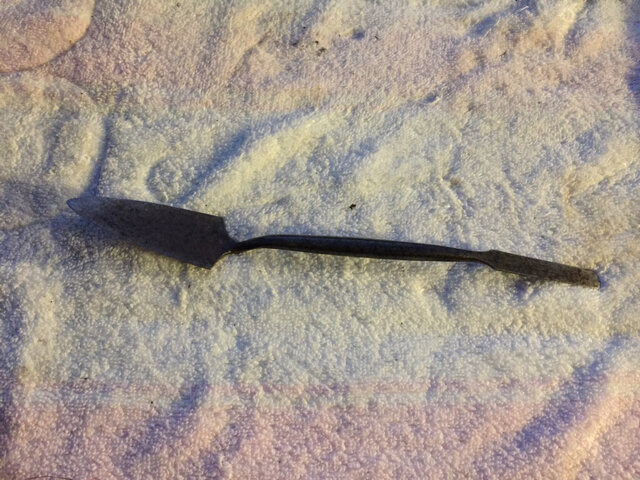

I also found this tool extremely useful in getting grease just where I wanted it, in the Birfield centre bore, around the outside of the knuckle, and with the slim end bearing grease into the outer bearing race before fitting the bearing.

It's a small pointing tool but it's come in handy for all sorts of things [emoji5]️.

Fitted the EBC rotors and pads. Amazing to find the Ferodo pads had worn down about 3mm over probably no more than 1500 miles or so and we're going wedge shaped. Not sure why but they did list two types for the 80. Must have fitted the wrong type!

The pads have a good coating on them and a self adhesive anti squeal backing. Come with their own copper ease sachet too. Will be interesting to see just how well they perform. Look good in yellow [emoji6].

Wheels on tomorrow. Might do the power steering pump while its up on sticks though. Also the speed sensor and its o ring seal and an oil change for the transfer box at he same time.

Except that I found fitting the half shafts to the well greased Birfield was easier done by aligning the spines up correctly and then letting the shaft's weight plus just a little downward pressure locate the snap ring in the lead-in machined in the Birfield. A little bit of a push on the snap ring with a screwdriver helped and it was then a doddle to tap the shaft in with the big rubber mallet [emoji6].

I also found this tool extremely useful in getting grease just where I wanted it, in the Birfield centre bore, around the outside of the knuckle, and with the slim end bearing grease into the outer bearing race before fitting the bearing.

It's a small pointing tool but it's come in handy for all sorts of things [emoji5]️.

Fitted the EBC rotors and pads. Amazing to find the Ferodo pads had worn down about 3mm over probably no more than 1500 miles or so and we're going wedge shaped. Not sure why but they did list two types for the 80. Must have fitted the wrong type!

The pads have a good coating on them and a self adhesive anti squeal backing. Come with their own copper ease sachet too. Will be interesting to see just how well they perform. Look good in yellow [emoji6].

Wheels on tomorrow. Might do the power steering pump while its up on sticks though. Also the speed sensor and its o ring seal and an oil change for the transfer box at he same time.

With much deliberation, and after reading posts here and knowing that my bearings had been spinning, I decided to increase the preload slightly. It ended up around 16 pounds pull and felt pretty good. Time will tell I guess.

Got it out on the road today. Two things. Firstly, I so missed driving my truck, I hadn't realised how much. Secondly, boy do I hate the period just after major surgery when I'm all on edge, listening for the slightest wrong sound or feeling something's wrong. Takes all the pleasure out of driving. Does anybody else get this?

Anyway, brakes feel good, for non broken in ones, I'll say a pretty good start. K&N filter, more noisy, lots more, might put the Denso one back just to rule out alien noises while I get used to the new parts.

Replaced the seals on the speed sensor take off on the side of the transfer box, removed and taped up the diff lock plug and changed the oil in the transfer box.

There is a tiny shaft seal, like a valve stem seal inside. I removed this using a 4" wire nail with the head against the inside of the seal.

New sensor and little gearbox that changes a KmH sensor speed to MpH.

Then went on to the window rubbers. Managed to pull out the old ones and push all but one back without taking the door cards off. The front ones are the most tricky with a change in metal runner inside the door on the straight side. I chamfered the end of the new rubber which worked on the drivers side but I had to take the door card off to do the passenger side.

The old rubbers were so hard you could hold them out straight in front of you. They were far harder within the door than outside. New ones nice and flexible. All the windows go up and down nicely now…and it's chilly out!!

Novelty to be able to open the windows…in the spring!! Whatever next?

Anyway, brakes feel good, for non broken in ones, I'll say a pretty good start. K&N filter, more noisy, lots more, might put the Denso one back just to rule out alien noises while I get used to the new parts.

Replaced the seals on the speed sensor take off on the side of the transfer box, removed and taped up the diff lock plug and changed the oil in the transfer box.

There is a tiny shaft seal, like a valve stem seal inside. I removed this using a 4" wire nail with the head against the inside of the seal.

New sensor and little gearbox that changes a KmH sensor speed to MpH.

Then went on to the window rubbers. Managed to pull out the old ones and push all but one back without taking the door cards off. The front ones are the most tricky with a change in metal runner inside the door on the straight side. I chamfered the end of the new rubber which worked on the drivers side but I had to take the door card off to do the passenger side.

The old rubbers were so hard you could hold them out straight in front of you. They were far harder within the door than outside. New ones nice and flexible. All the windows go up and down nicely now…and it's chilly out!!

Novelty to be able to open the windows…in the spring!! Whatever next?

Attachments

I have decided to slacken my wheel bearings. Not sure if I imagined a rumbling from them but I've decided I'm not entirely happy. Revisit tomorrow.

Similar threads

- Replies

- 4

- Views

- 658