While we wait with 'bated breath for Chris to unveil 'The Blue One' . . . .

I've just about finished fettling the 'cheap' (HA

) Ifor Williams GX106 Plant Trailer (not a Landcruiser - but close to it

).

As always, once I start digging into a vehicle/trailer/ piece of kit I find all sorts of things wrong that I "Just have to fix". This thing cost me £1,000, but I have now spent another £1,500 on it

). At least I know that everything works.

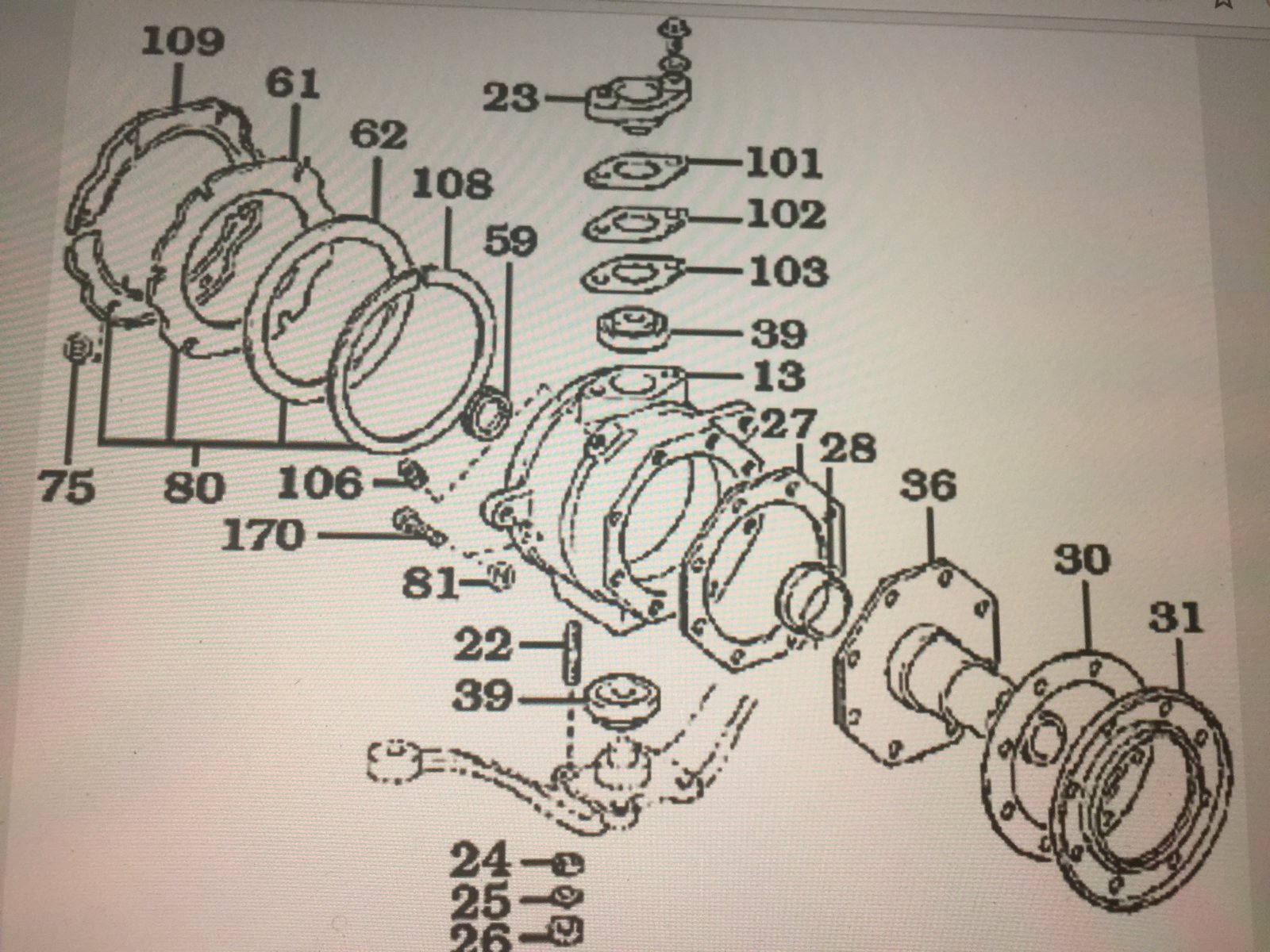

The brakes were totally shot (some shoes didn't have any linings at all):

The cables were seized:

The only good tyre was the wrong size and there wasn't a spare - One new wheel and five tyres purchased.

The old wheels and the brake backplates were powder-coated and new brake assemblies and cables bought.

Two of the wheels bearings were shot - so four new ones bought.

I found one broken spring so two springs for the rear axle and a set of eye bushes for the others. All new 'U' bolts & bump stops.

The axles were stripped back to metal and heavily painted (Hammerite).

Even the 'Energy Store' on the hitch was shot - the spring fell out as a heap of 'anti-shake' washers

).

Some of the welds on the ramp had failed so it came off, was re-welded and new Checker Plate fitted (3mm instead of the original 2mm).

Once it starts going together it looks (and feels) good.

The re-built brakes look fit for purpose (10" Knott brakes).

The wiring was 're-done' with 7-core cable and a pair of junction boxes. All the marker lights and some of the reflectors were replaced. They all work!

This is a 2007 trailer. Later models have three pairs of heavy-duty tie-downs fitted as standard. I got a set from Ifor Williams. They fit to the sloping sides - above and clear of digger tracks.

Almost there now. I just need to repair the hand winch and fit it.

Now I need to find a digger !

Bob.

) Ifor Williams GX106 Plant Trailer (not a Landcruiser - but close to it

).

). At least I know that everything works.