Not quite " maintenance today" but a catch up on a few jobs on the old 24V auto I did on the weekends and nights prior to Lincombe meeting a couple of weeks ago.

It had always driven well from the day I got it in 2015 with no issues but had it in storage for a couple of years while I got the Collie thing out of my system.

When I got it out it passed the MOT no advisories but I noticed a touch of oil on the n/s swivel hub and that was the start.

Replaced:-

Front driveshafts and CV's ( gen Toyota)

Swivel bearings, Wheel bearings, seals and gaskets.

All brake discs and pads ( gen Toyota)

All brake hoses to steel braided extended.

Rebuilt n/s front calliper, rest fine.

Replaced std suspension with Dobinsons Front springs and dampers, Rear springs were Suplex with Dobinsons dampers, replaced steering damper with Ironman unit.

Fitted castor correction plates as the drop boxes hadn't arrived in time but it drives ans steers well.

Replaced after market wheels on 275's BFG's with black standard wheels shod with new 285 KO2's

Replaced Maggi roof tent with I-Kamper to give us more room.

Replaced ali bumper I had on with a JDM Toyota one which will make fitting the Aisin ( Toyota fitment) winch easier.

Took rear ( 2nd row) seats out and installed dog cage on one side and ARB fridge in the other side, draw system next to be installed when I will probably change the rear springs for the matching Dobinson ones.

Changed the reg no to N 80 MUD.

so after all that it looked like this:-

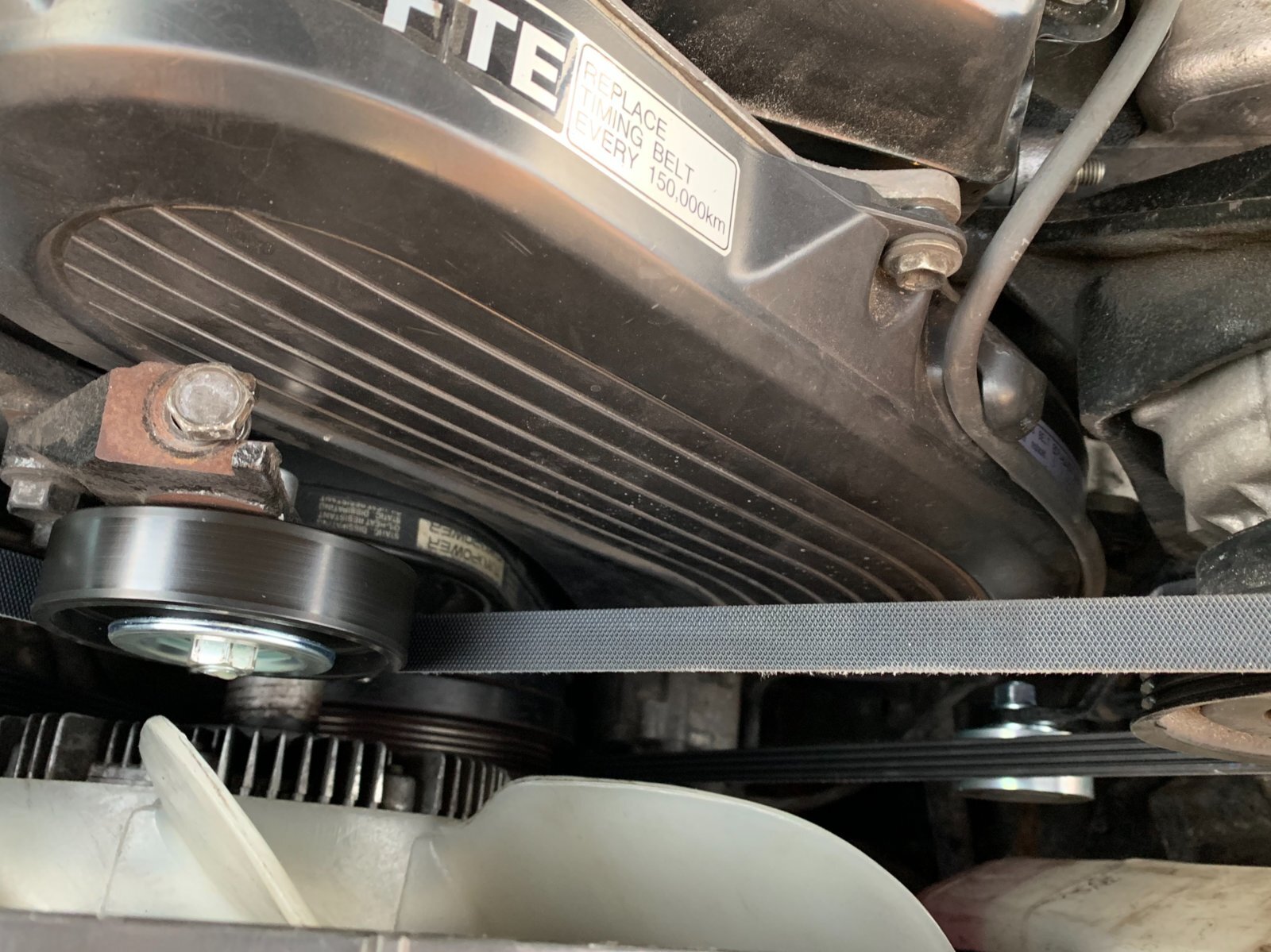

Got packed up for Lincombe, drove down beautifully, only to find when we got there that all the elastictrickery had escaped and the bloody batteries were nearly flat. Got a jump start the next morning to get home and replaced the ( like new Lucas recon unit) alternator with the one off "Mud" and we're charging along again.

Hopefully we'll get to the next meeting without any dramas.

), I have 10 months MOT left

), I have 10 months MOT left

).

). ).

).