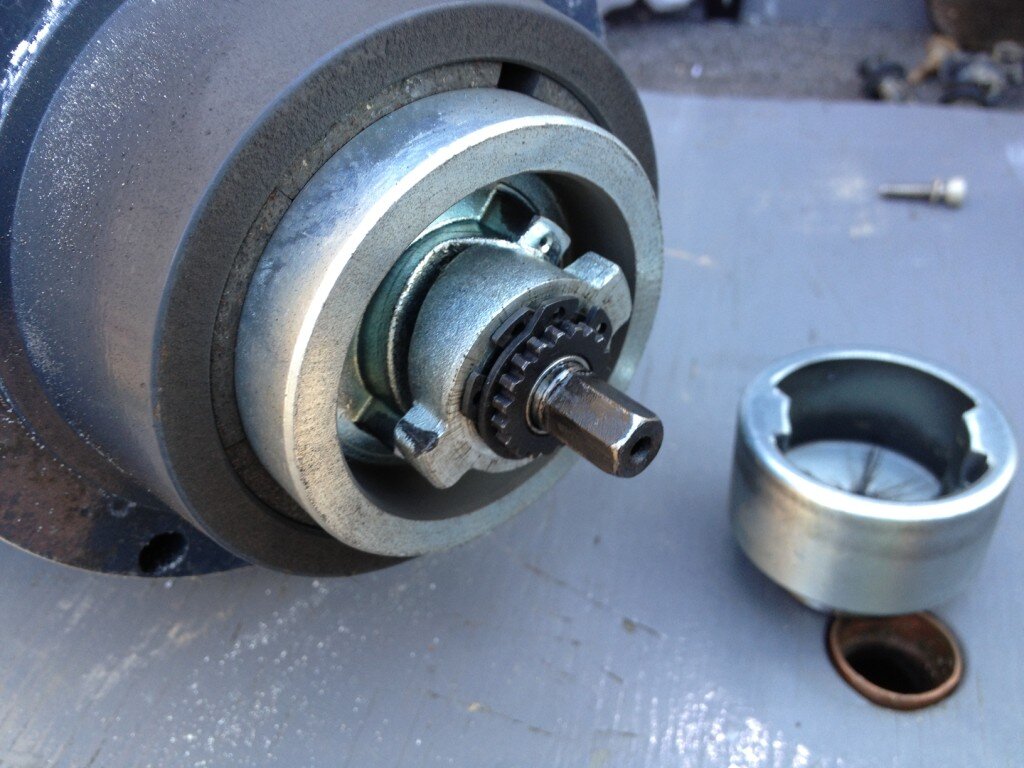

As I dont have anything to do to the truck in prep for Lincomb I decided to service my winch as I bought it secondhand from off of eBay and I've now had it for a year and have no idea of its internal condition. So without any guidance or knowledge of it I started to systematically strip it apart starting at the cone brake and gearbox end. It all came apart very well and although it had suffered some water ingress clearly down the freespool lever shaft, it really was not so bad. All the same I've stripped it to bits and decreased it all ready to fit back together.

I have a load of photos to post, but a couple of questions to ask before I start posting them up.

What grease shall I use to put the gearbox back together General Purpose or Graphite? In the back of my head somewhere I seem to remember a conversation on the subject that subjected Graphite/CV grease was the way to go.

I could also do with a little pointer on how to remove the back cover from off of the motor. I've removed the motor from off of the winch frame by removing the two very long bolts that pass through the motor to the drum frame and I've removed the two small Philips screws that hold the motor end cap onto the body of the motor, but can only pull them apart by 10/15mm before experiencing some resistance! Do I just need to pull harder or is there something Else I need to remove?

I have a load of photos to post, but a couple of questions to ask before I start posting them up.

What grease shall I use to put the gearbox back together General Purpose or Graphite? In the back of my head somewhere I seem to remember a conversation on the subject that subjected Graphite/CV grease was the way to go.

I could also do with a little pointer on how to remove the back cover from off of the motor. I've removed the motor from off of the winch frame by removing the two very long bolts that pass through the motor to the drum frame and I've removed the two small Philips screws that hold the motor end cap onto the body of the motor, but can only pull them apart by 10/15mm before experiencing some resistance! Do I just need to pull harder or is there something Else I need to remove?

Last edited:

I am surprised that there is not an 'O' ring of some kind on the shaft

I am surprised that there is not an 'O' ring of some kind on the shaft