Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An Ultra slow Ultra4 build

- Thread starter BRE Fabrications LTD

- Start date

BRE Fabrications LTD

Well-Known Member

Plan is to convert those rims to bead lock myself. Just need to draw up the rings and have em cut. Simples...No beadlocks?

Animal Mother

Well-Known Member

- Joined

- Sep 27, 2016

- Messages

- 839

- Country Flag

Eagerly awaiting updates on this cool build.

BRE Fabrications LTD

Well-Known Member

Well, I wasn't lying when I said Ultra slow!!

I went and watched the Ultra4 King of Britain race weekend before last. It was held in Bovington on some MOD tank testing ground. I helped out in the pits for a team racing. To say it was an awesome turnout was an understatement. 42 teams from the UK and across Europe rocked up. The cars were awesome and I managed to steal a fair but with my eyes. Also V8's are definitely the engine of choice. The win eventually went to a UK competitor, Jim Marsden, owner of Gigglepin winches. His vehicle was nuts. He's running a LSX454 7.2l V8.

I realised from looking at other Modified class vehicles that I can ditch far more of the body than I previously realised. So the sawzall will be coming out in anger once again. This is a good indication of what I'll be shooting for, this belongs to Nick Bolt from Zero53 Racing:

Check out a couple of the race recaps here:

So back in the workshop over the weekend. I'm still very much in the cutting and grinding stages. I started stripping down the Patrol axles.

I had a set of 80 axles lying about so thought a side by side comparison would be interesting. Despite how the photos look the patrol axles are a smidge thicker than the 80's, but just a bit +/- 1mm in diameter. I am guessing its the 9" diff that really sets these apart from the 80 series front axle (the ones with the ABS ring on them)...

[/QUOTE]

[/QUOTE]

Other than that I have various engine parts (intake manifold, tappet covers and cam belt covers) at a machine cleaning company to be chemically cleaned and blasted. These will be ready this week after which they'll be going to a panel beater to be painted, I gotta have some bling in the engine bay. Next up I'll be having the axle housings blasted, from there it'll be onto the 4-link design for the front and rear.

The first race is next year April so going to have to pull finger on this to make sure its ready!

I went and watched the Ultra4 King of Britain race weekend before last. It was held in Bovington on some MOD tank testing ground. I helped out in the pits for a team racing. To say it was an awesome turnout was an understatement. 42 teams from the UK and across Europe rocked up. The cars were awesome and I managed to steal a fair but with my eyes. Also V8's are definitely the engine of choice. The win eventually went to a UK competitor, Jim Marsden, owner of Gigglepin winches. His vehicle was nuts. He's running a LSX454 7.2l V8.

I realised from looking at other Modified class vehicles that I can ditch far more of the body than I previously realised. So the sawzall will be coming out in anger once again. This is a good indication of what I'll be shooting for, this belongs to Nick Bolt from Zero53 Racing:

Check out a couple of the race recaps here:

So back in the workshop over the weekend. I'm still very much in the cutting and grinding stages. I started stripping down the Patrol axles.

I had a set of 80 axles lying about so thought a side by side comparison would be interesting. Despite how the photos look the patrol axles are a smidge thicker than the 80's, but just a bit +/- 1mm in diameter. I am guessing its the 9" diff that really sets these apart from the 80 series front axle (the ones with the ABS ring on them)...

[/QUOTE]

[/QUOTE]Other than that I have various engine parts (intake manifold, tappet covers and cam belt covers) at a machine cleaning company to be chemically cleaned and blasted. These will be ready this week after which they'll be going to a panel beater to be painted, I gotta have some bling in the engine bay. Next up I'll be having the axle housings blasted, from there it'll be onto the 4-link design for the front and rear.

The first race is next year April so going to have to pull finger on this to make sure its ready!

BRE Fabrications LTD

Well-Known Member

The axles are now at the blasting company being cleaned up. In the meantime I started putting the bits on the motor back that I had cleaned up previously. I gave them a lick of high temp paint too. Next up I need to finish servicing the PS pump so I can get that and the drive belts back on. Then I can bolt it up to the gearbox for hopefully the last time for a while and get it back into the cruiser.

I should get the axles back this week so once the motor is back in I can get the axles put back together and get them under the 70 with the tyres on. That way I can start mocking things up.

I should get the axles back this week so once the motor is back in I can get the axles put back together and get them under the 70 with the tyres on. That way I can start mocking things up.

Don't like the adverts? Click here to remove them

Mama, that looks like business

BRE Fabrications LTD

Well-Known Member

If your truck is gonna look anything like Nick Bolt's pictured above i think i need you to build me a daily driver Ryan

I haven't seen his truck in the flesh yet, but if I can manage to get close to what he has built I'll be stoked. I'll no doubt make plenty of mistakes along the way but confident it's going to turn out pretty decent.

Now if I can just get past the servicing and tearing down stage and actually get into building stuff I'll be happy.

BRE Fabrications LTD

Well-Known Member

Hey Tommy, I have Y61's.Have you got y60 or 61 axles?

BRE Fabrications LTD

Well-Known Member

Well all in I had a fairly productive weekend. I picked up the axles from the blasting company on Fri, have to say I'm very pleased with how they turned out.

Before:

After:

I had a bit more grinding to do on these to get the what was left of the brackets off. Then gave them a lick of weld through zinc primer to stop any surface rust developing. I haven't used it before so we'll have to wait and see what it's like to weld on...

This is them ready for re assembly...

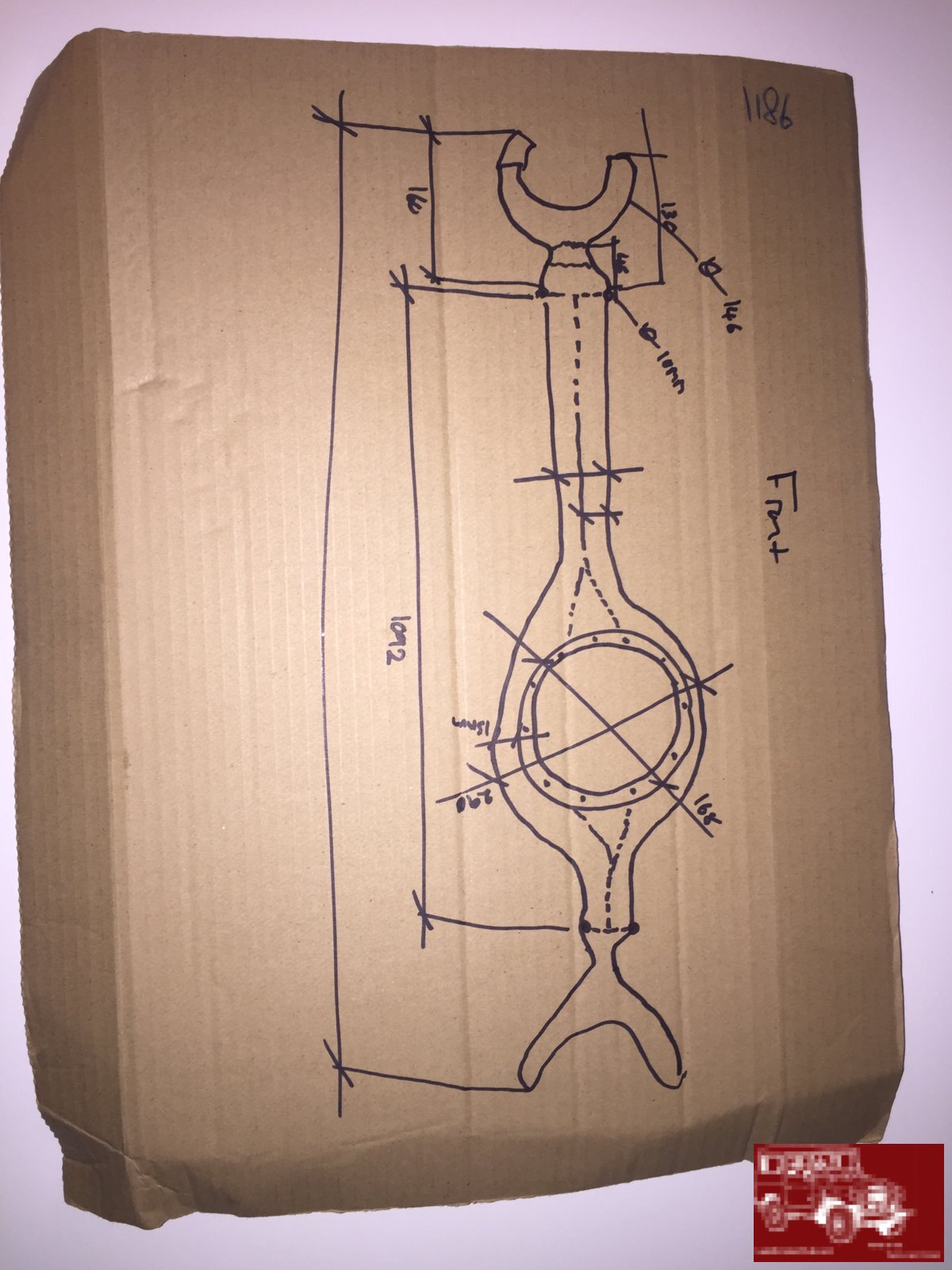

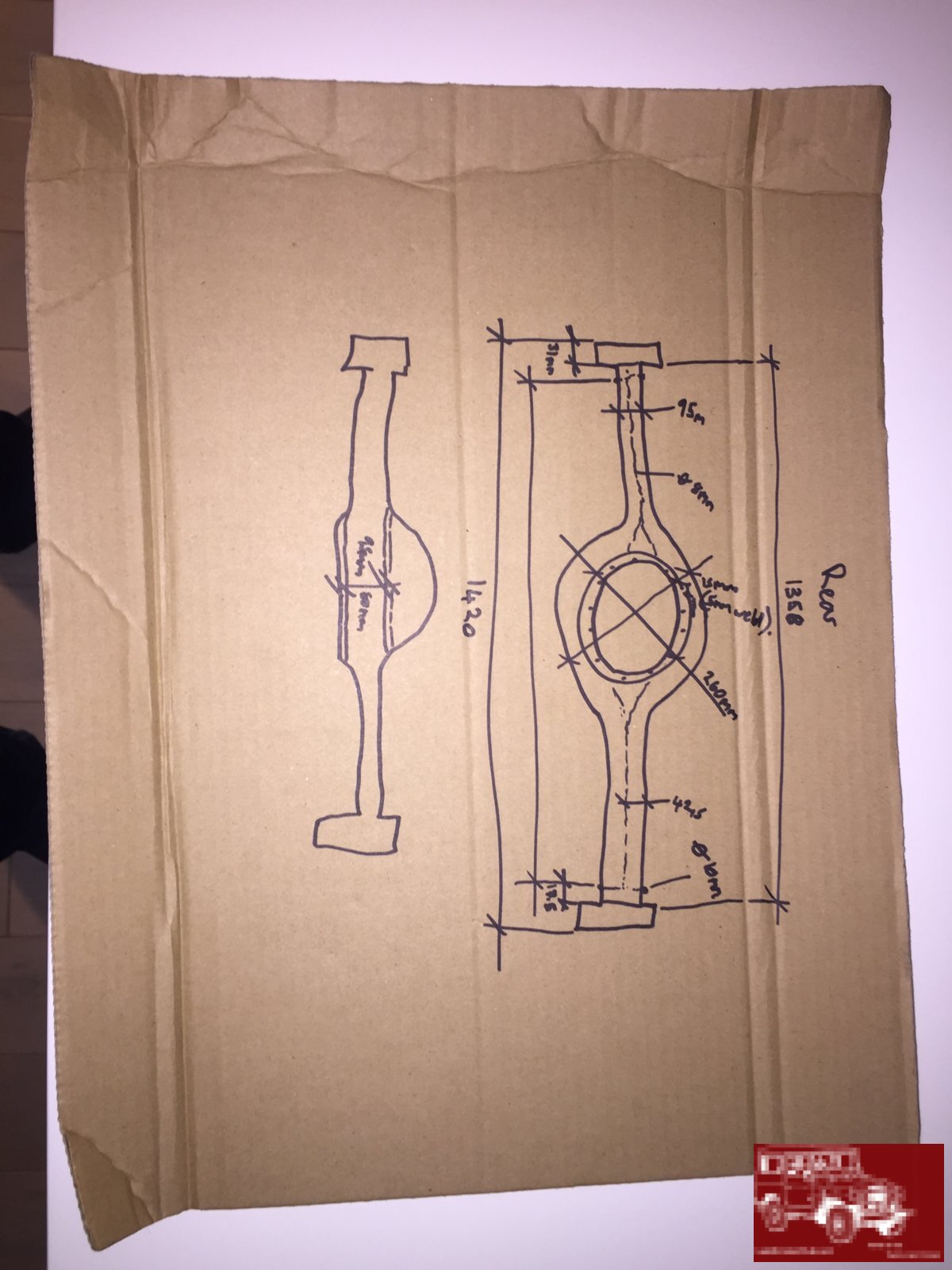

After that I drew up up a few fag packet sketches...

Then took a few photo's with a steel rule so I could scale them in the CAD software I use. This basically lets me trace over the photos to achieve the curves I can't measure accurately.

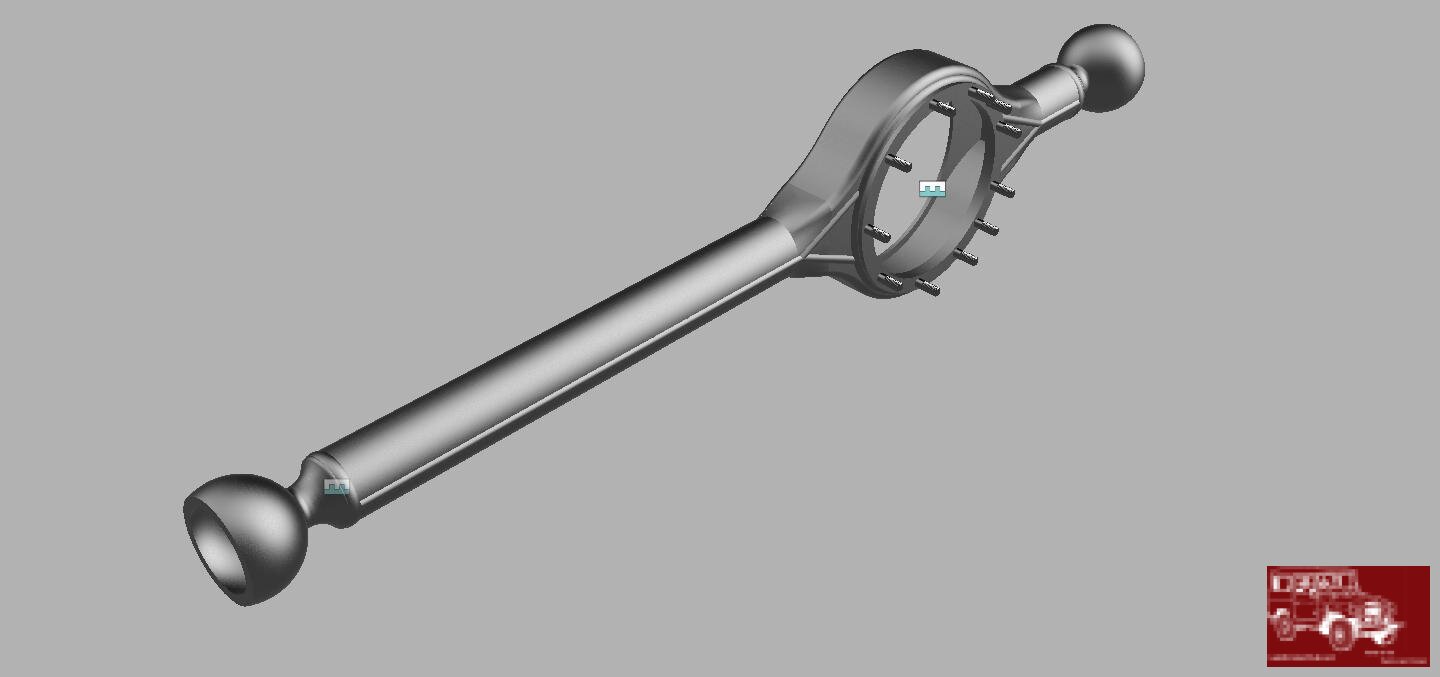

And finally drew up a 3D model in CAD.

I'll need to take a few check dimensions to make sure the model is accurate enough. The perspective in the photos can throw tings out a bit so it will need to be rechecked. The reason I have modelled the axle is so that I can design an axle truss, link brackets and shock mounts. Once I have that figures out I can send of the drawings to have parts laser cut and then weld the lot onto the axles.

Something like this practice model I did is what I want to achieve. Whats really cool with the CAD software is that you can actually cycle through the suspension to see how it moves and check for any clashes. For this to work properly you need to spend a bit of time setting up your joint types and restricting their freedom of movement to reflect what it will be in reality.

Cross axled:

Full bump:

Full droop:

Next up I need to model the rear axle. other than that I finished replacing the O-rings on the Power steering pump and put that back on the motor along with the fan belt, fuel line and pressure regulators.

Before:

After:

I had a bit more grinding to do on these to get the what was left of the brackets off. Then gave them a lick of weld through zinc primer to stop any surface rust developing. I haven't used it before so we'll have to wait and see what it's like to weld on...

This is them ready for re assembly...

After that I drew up up a few fag packet sketches...

Then took a few photo's with a steel rule so I could scale them in the CAD software I use. This basically lets me trace over the photos to achieve the curves I can't measure accurately.

And finally drew up a 3D model in CAD.

I'll need to take a few check dimensions to make sure the model is accurate enough. The perspective in the photos can throw tings out a bit so it will need to be rechecked. The reason I have modelled the axle is so that I can design an axle truss, link brackets and shock mounts. Once I have that figures out I can send of the drawings to have parts laser cut and then weld the lot onto the axles.

Something like this practice model I did is what I want to achieve. Whats really cool with the CAD software is that you can actually cycle through the suspension to see how it moves and check for any clashes. For this to work properly you need to spend a bit of time setting up your joint types and restricting their freedom of movement to reflect what it will be in reality.

Cross axled:

Full bump:

Full droop:

Next up I need to model the rear axle. other than that I finished replacing the O-rings on the Power steering pump and put that back on the motor along with the fan belt, fuel line and pressure regulators.

BRE Fabrications LTD

Well-Known Member

I semi put the axles back together this weekend, just enough to be able to mount the wheels so that I can put the axles under the 70 and locate them where I am planning to run them.

This is at 17.5" belly height and a Wheel base of 112.5". I have decided to pull the front axle forward as opposed to pushing the back axle backwards. Reason being I want to try and keep the weight distribution as 50/50 as feasible. It'll also give an awesome approach angle, I know it looks odd so I still need to think of how I can finish it whilst keeping it looking ok. Though i do still need to settle on a final wheel base, alot of folk are racing cars with 116" wheelbases...

I'm also thinking I may narrow the from end somewhat...

Anyway at least now I can start looking at the suspension and steering setup, of which I think the steering is going to be the hardest. I want to run a 4-link on the front but in order to stay class compliant I need a mechanical steering linkage. So I have been reading up on bell crank steering setups kind of like this...

But in order to do this I'll need to convert to LHD. Why go to this extent, well the suspensions going to be the most important element on the car. Being able to get rid of the panhard and run a 4-link will give me a superior setup to what most of the modified guys are running. It also allows me to ditch the drag link, unlike what is shown in the photo. If I use a double ended ram this will essentially be the drag link. Also steering boxes seem to take a huge amount of punishment especially from shock loading when a wheel hits and deflects off of something. Typical failures are stripped or snapped sector shafts. So if I can make this work I get a stronger and better performing setup than running radius arms with p/hard and std steering. That and I like the challenge of trying something a but different to anything else I have seen on the UK & European trucks.

This is at 17.5" belly height and a Wheel base of 112.5". I have decided to pull the front axle forward as opposed to pushing the back axle backwards. Reason being I want to try and keep the weight distribution as 50/50 as feasible. It'll also give an awesome approach angle, I know it looks odd so I still need to think of how I can finish it whilst keeping it looking ok. Though i do still need to settle on a final wheel base, alot of folk are racing cars with 116" wheelbases...

I'm also thinking I may narrow the from end somewhat...

Anyway at least now I can start looking at the suspension and steering setup, of which I think the steering is going to be the hardest. I want to run a 4-link on the front but in order to stay class compliant I need a mechanical steering linkage. So I have been reading up on bell crank steering setups kind of like this...

But in order to do this I'll need to convert to LHD. Why go to this extent, well the suspensions going to be the most important element on the car. Being able to get rid of the panhard and run a 4-link will give me a superior setup to what most of the modified guys are running. It also allows me to ditch the drag link, unlike what is shown in the photo. If I use a double ended ram this will essentially be the drag link. Also steering boxes seem to take a huge amount of punishment especially from shock loading when a wheel hits and deflects off of something. Typical failures are stripped or snapped sector shafts. So if I can make this work I get a stronger and better performing setup than running radius arms with p/hard and std steering. That and I like the challenge of trying something a but different to anything else I have seen on the UK & European trucks.

- Joined

- Feb 2, 2013

- Messages

- 17,106

Probably won't work with your criteria but while building a car in my daydreams i have always thought the width should determine the length . A Lotus Elise is supposed to be one of the best handling cars in the world so find its footprint and increase it in equal measures until it fits your truck .

A pointless post but daydreams die with us if we don't share them

A pointless post but daydreams die with us if we don't share them

stumog

Well-Known Member

- Joined

- Oct 3, 2012

- Messages

- 3,853

- Country Flag

Why not move the cab further forward and chop out the bulkhead and floor?

The front axle does look to far forward, if you got rid of the cab and made a tube body it would look better. if you used the front end it would have the cruiser look to it.

The front axle does look to far forward, if you got rid of the cab and made a tube body it would look better. if you used the front end it would have the cruiser look to it.

BRE Fabrications LTD

Well-Known Member

Why not move the cab further forward and chop out the bulkhead and floor?

The front axle does look to far forward, if you got rid of the cab and made a tube body it would look better. if you used the front end it would have the cruiser look to it.

Hey Stu,

The more I'm getting into this the more I'm thinking go full tubular and just use the cruiser fenders, bonnet, grill and chassis rails which keeps me class compliant. I think your idea of a tub body will work and probably the route I'll end up going. Maybe something like this...

BRE Fabrications LTD

Well-Known Member

Hey Ben,

Congrats on the wedding dude!

Ya, thats kind of what I'm thinking along with moving the fenders forward to keep the looks proportional.

Congrats on the wedding dude!

Ya, thats kind of what I'm thinking along with moving the fenders forward to keep the looks proportional.