BRE Fabrications LTD

Well-Known Member

Hey Guys,

Been a while and haven't made much progress on the truck with the holidays and all that, I did say this was going to be a slow build!

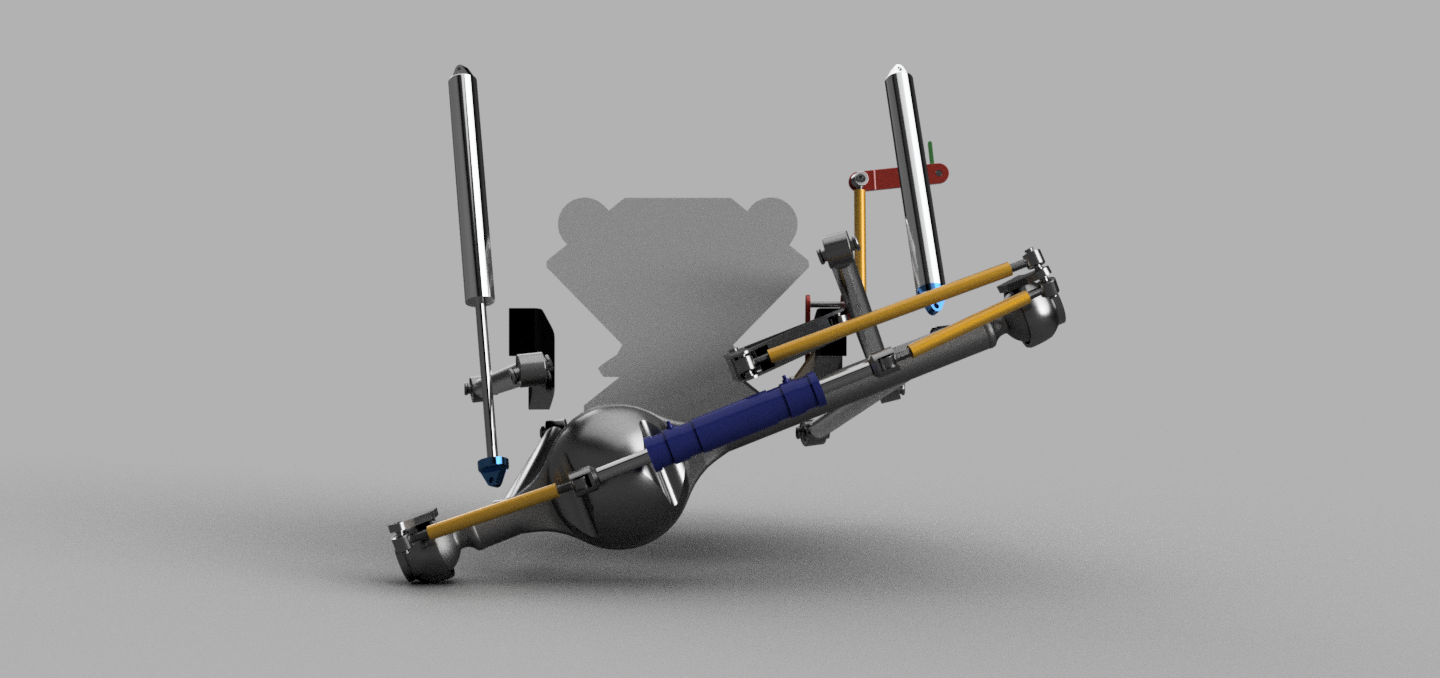

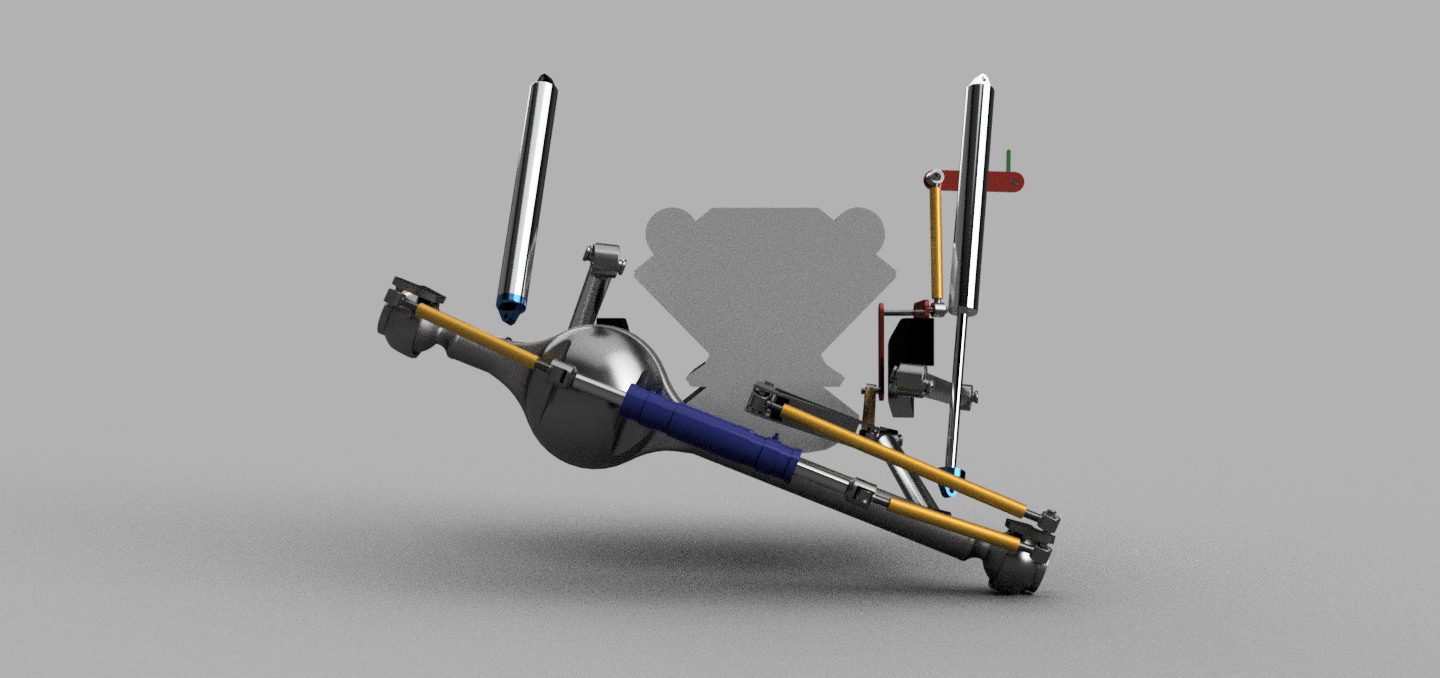

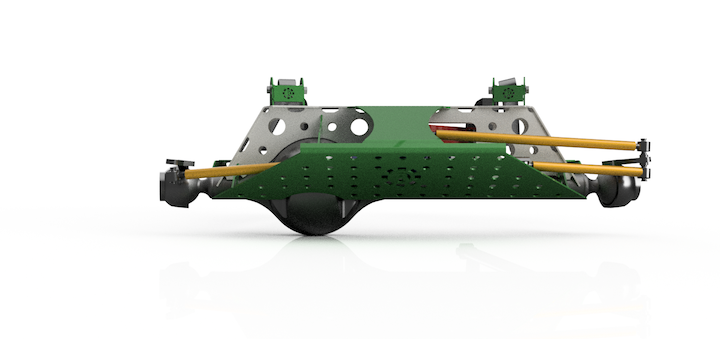

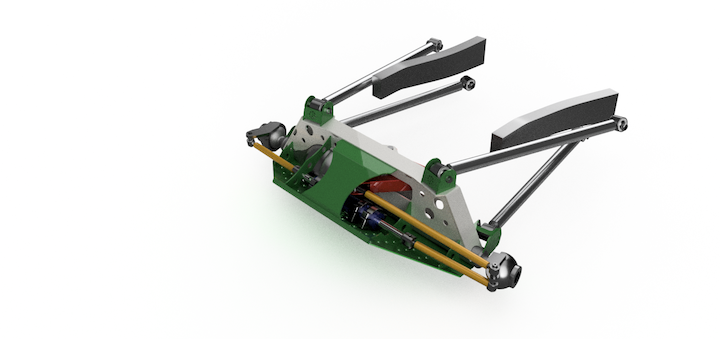

Anyway back to what I have actually managed to achieve. I went ahead and played around in cad to work out what the bumpsteer would be like with the bell crank setup. These are a few shots of the front axle flexed out, I put in links to where the steering wheel will be approx. I get around 15" of bump steer input, but this will be damped sound in the steering so I am thinking in reality it will be negligible. The green indicator shows the bumpsteer generated by cycling through the range of the suspension travel.

So I am going to continue pursuing this steering setup. Worst case if I can't get it to work I'll race in Legends class with full Hydro until the next season.

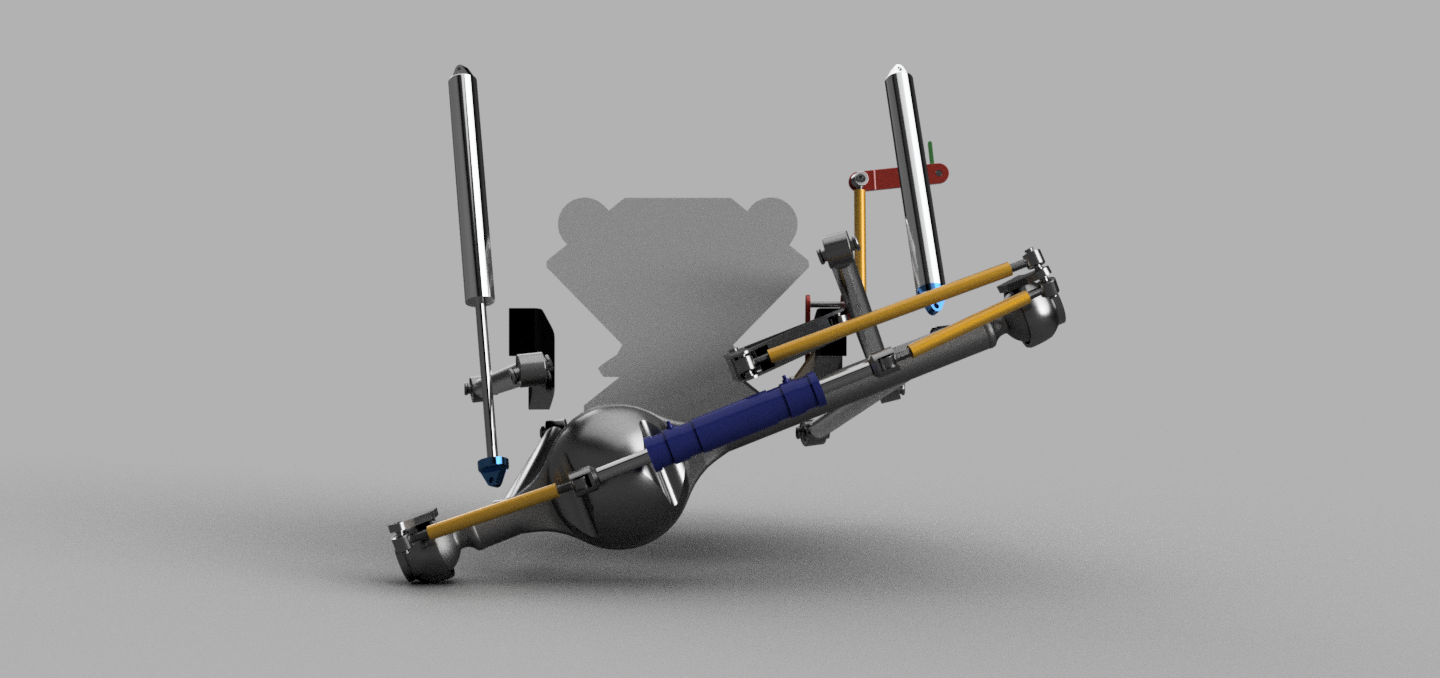

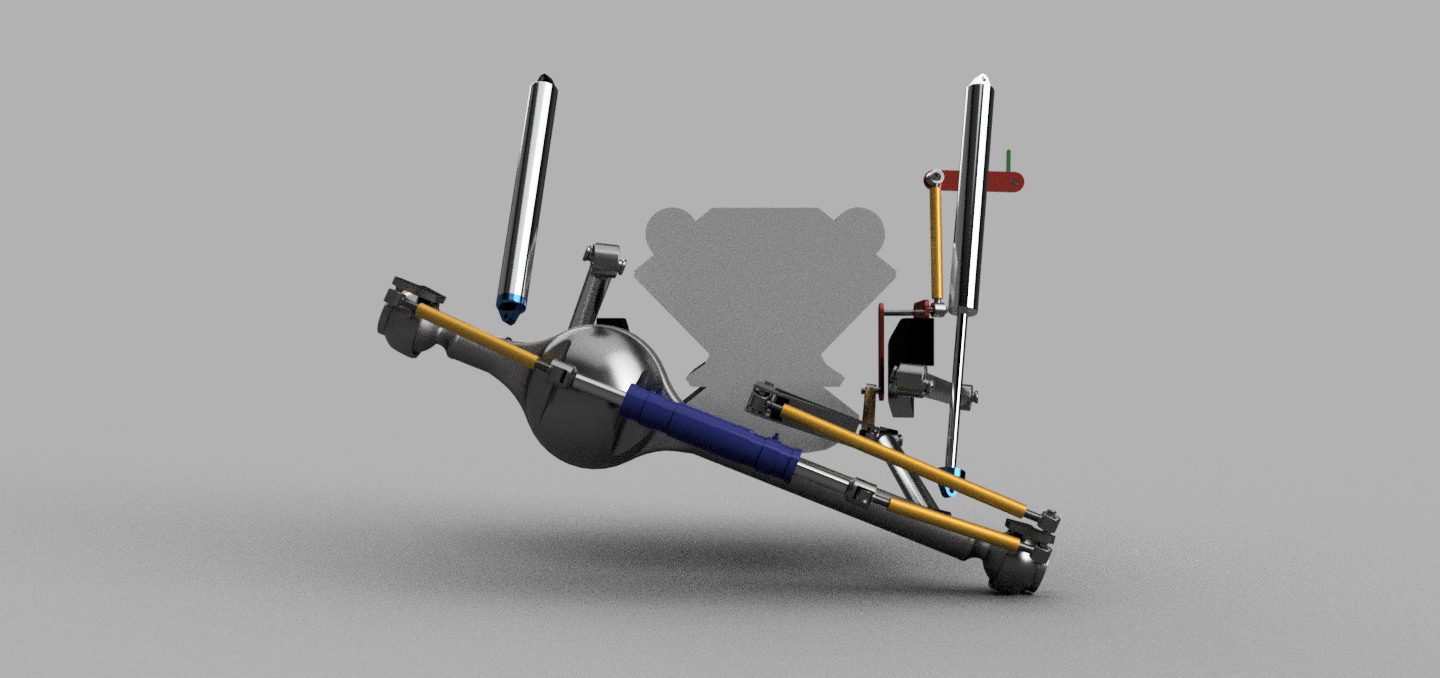

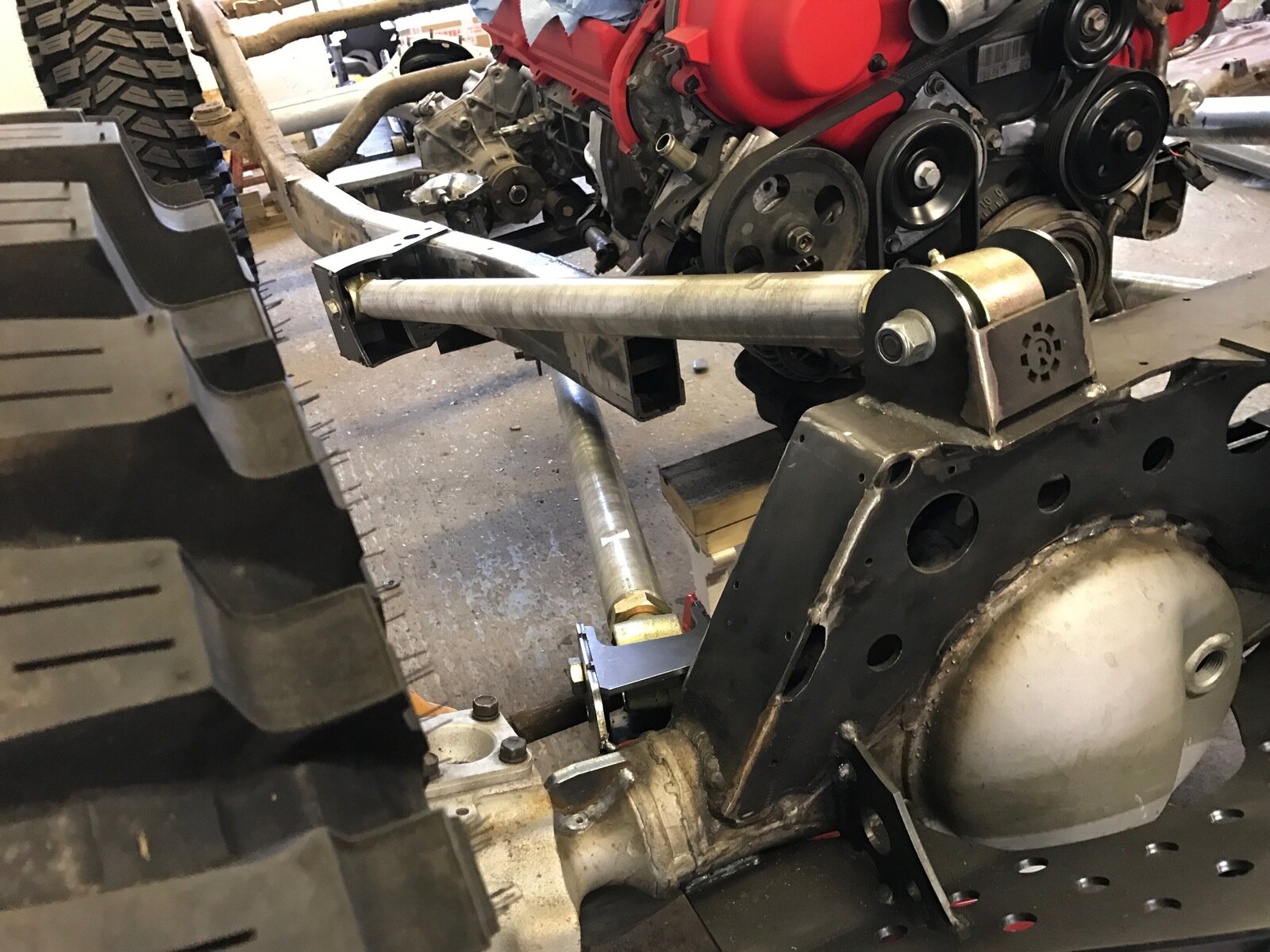

So that has led me to start playing around with links. I mate of mine had to abandon his build due to a change in circumstances. He bought a roller and parted it out. So i had the opportunity to pick up a set of 2.5" 7075 Aluminium links with 2.5" Johnny Joints. His wheelbase was going to be 116" so I figured why not try give it a shot with his link lengths and see what I can come up with. worst case I may need to trim his links down or cut longer ones.

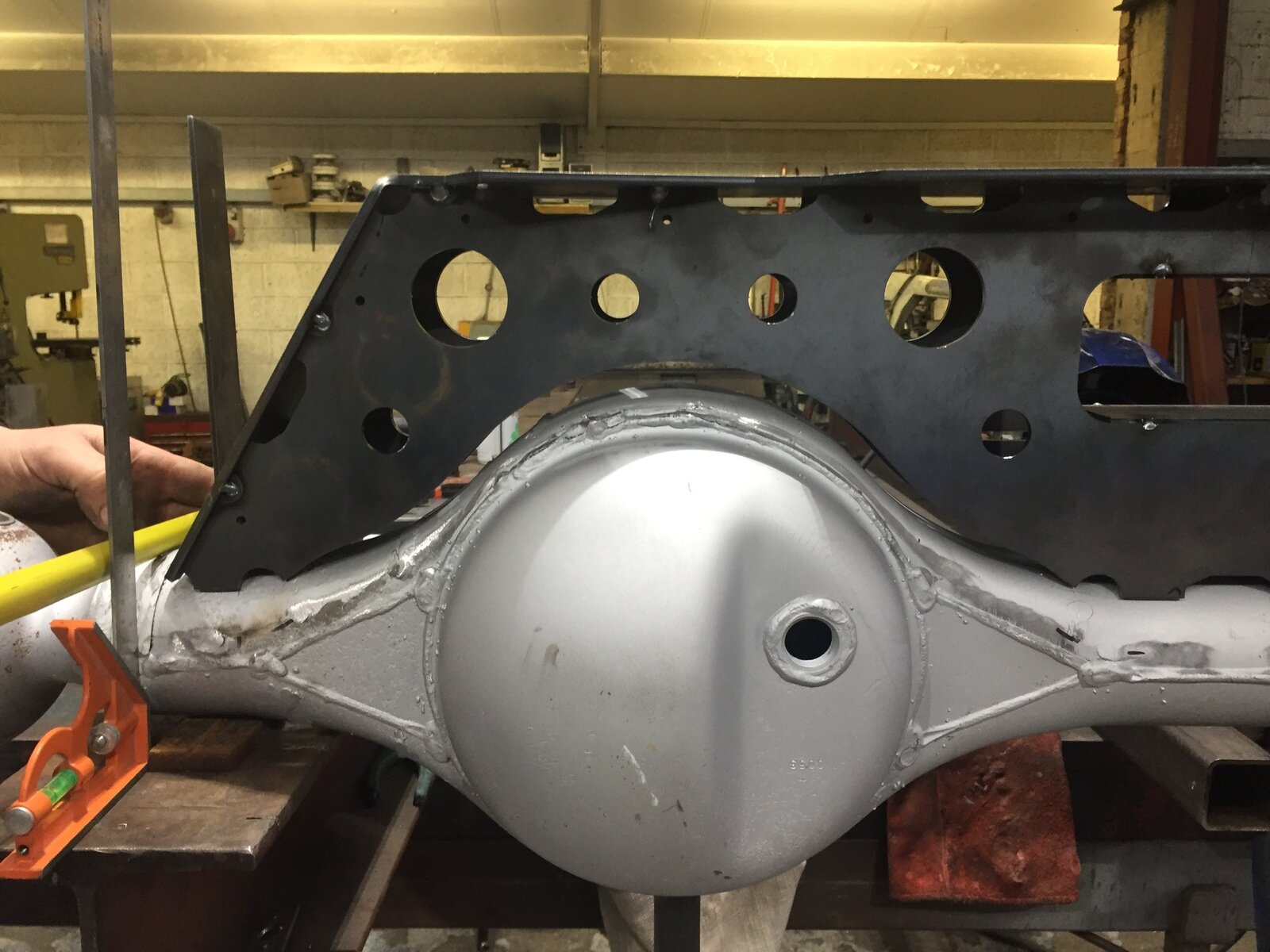

So this just a little test fitting to see roughly where things can fit after which I took measurements and plugged them into the Triaged 4-link calculator.

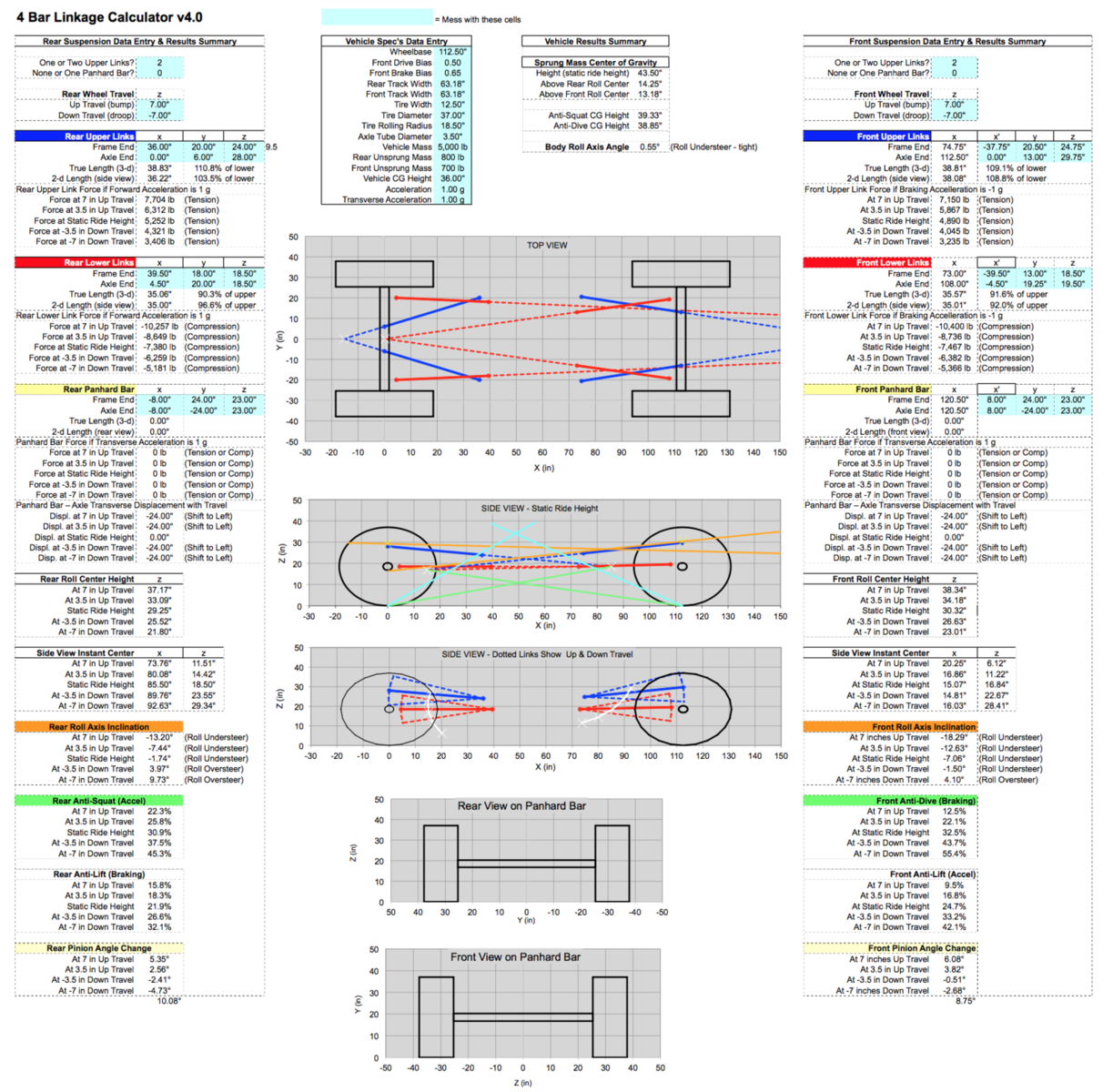

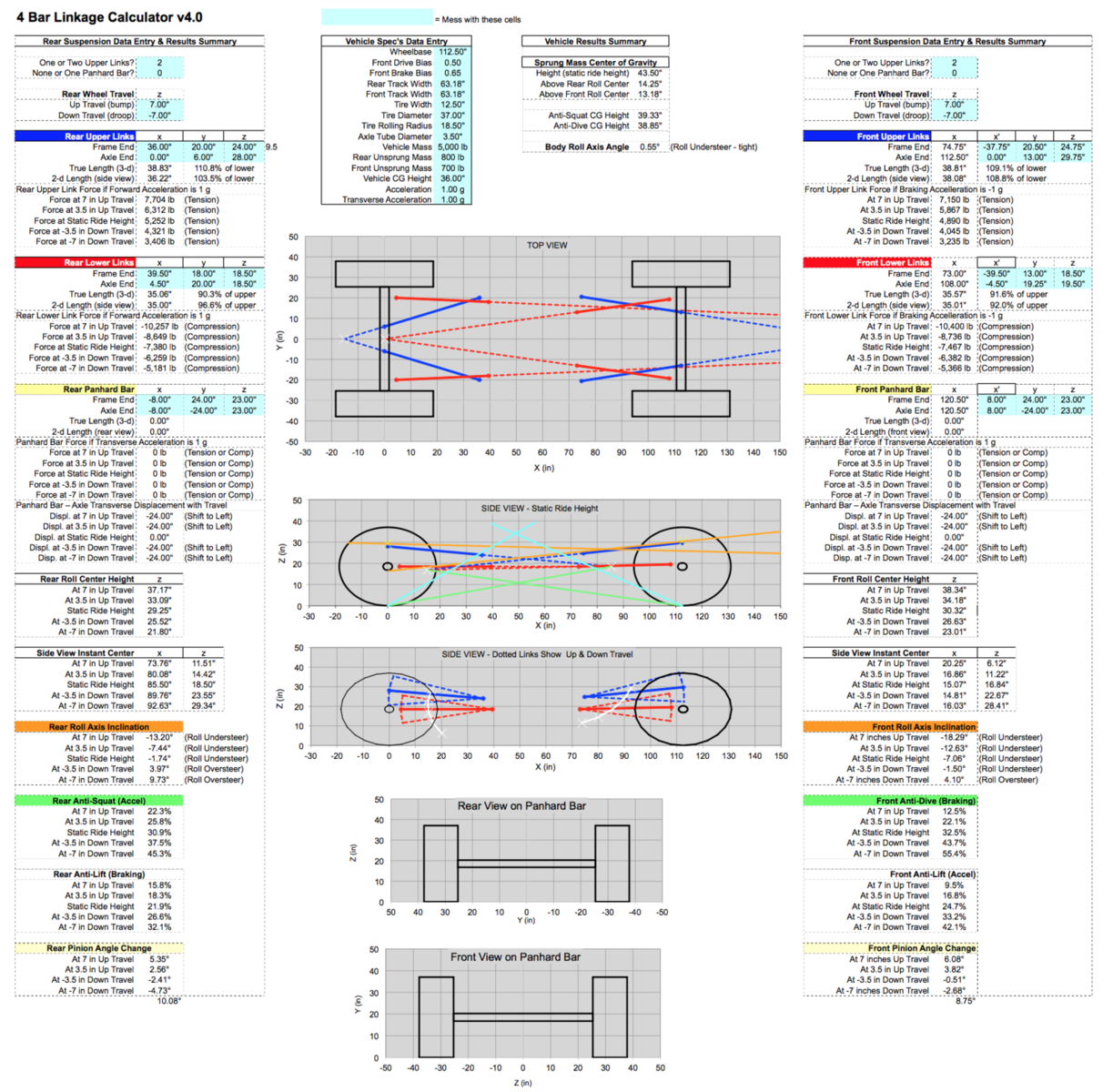

As the links are fitted in the pics above the numbers turned to not be great. The diff pinion angle change was in excess of 20' and put the pinion pointing into the motor at full compression. But it was a starting point. So I played around in the Triaged calculator and in CAD to figure out what was feasible and have come out with the following numbers, Ignore the rear I haven't started on that yet.

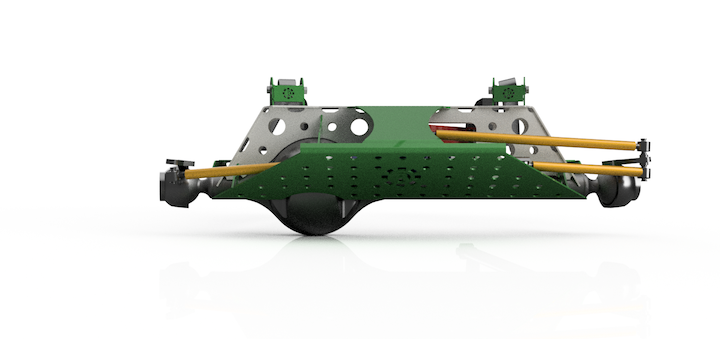

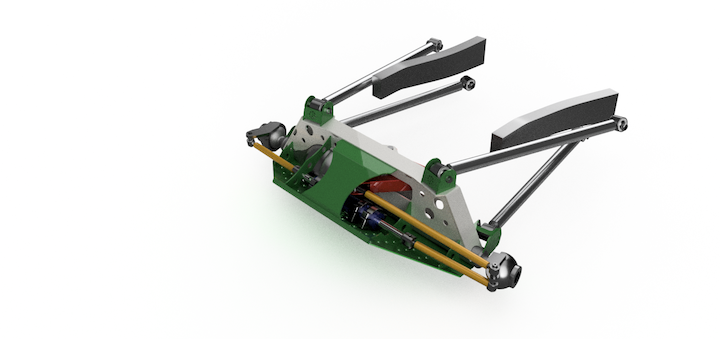

So from that I have gone on to start the design for the truss, Ram mount, Bellcrank and link mounts. I still need to do the chassis mounts. This is where I am at.

I need to still do the shock mounts and bump stop pads and then tidy up a few of the tabs. I like using a slot and tab setup, it saves me having to rely on a tape measure too much and helps keep things symmetric.

Other than that the shocks are ordered and should be with me at the end of the month. I went for the King 2.5"x14" RR coil overs. So looking forward to getting those in. By then I should have all the laser cutting done for the front truss and chassis mounts.

Been a while and haven't made much progress on the truck with the holidays and all that, I did say this was going to be a slow build!

Anyway back to what I have actually managed to achieve. I went ahead and played around in cad to work out what the bumpsteer would be like with the bell crank setup. These are a few shots of the front axle flexed out, I put in links to where the steering wheel will be approx. I get around 15" of bump steer input, but this will be damped sound in the steering so I am thinking in reality it will be negligible. The green indicator shows the bumpsteer generated by cycling through the range of the suspension travel.

So I am going to continue pursuing this steering setup. Worst case if I can't get it to work I'll race in Legends class with full Hydro until the next season.

So that has led me to start playing around with links. I mate of mine had to abandon his build due to a change in circumstances. He bought a roller and parted it out. So i had the opportunity to pick up a set of 2.5" 7075 Aluminium links with 2.5" Johnny Joints. His wheelbase was going to be 116" so I figured why not try give it a shot with his link lengths and see what I can come up with. worst case I may need to trim his links down or cut longer ones.

So this just a little test fitting to see roughly where things can fit after which I took measurements and plugged them into the Triaged 4-link calculator.

As the links are fitted in the pics above the numbers turned to not be great. The diff pinion angle change was in excess of 20' and put the pinion pointing into the motor at full compression. But it was a starting point. So I played around in the Triaged calculator and in CAD to figure out what was feasible and have come out with the following numbers, Ignore the rear I haven't started on that yet.

So from that I have gone on to start the design for the truss, Ram mount, Bellcrank and link mounts. I still need to do the chassis mounts. This is where I am at.

I need to still do the shock mounts and bump stop pads and then tidy up a few of the tabs. I like using a slot and tab setup, it saves me having to rely on a tape measure too much and helps keep things symmetric.

Other than that the shocks are ordered and should be with me at the end of the month. I went for the King 2.5"x14" RR coil overs. So looking forward to getting those in. By then I should have all the laser cutting done for the front truss and chassis mounts.

It's fantastic to see this coming on, Ryan.

It's fantastic to see this coming on, Ryan.