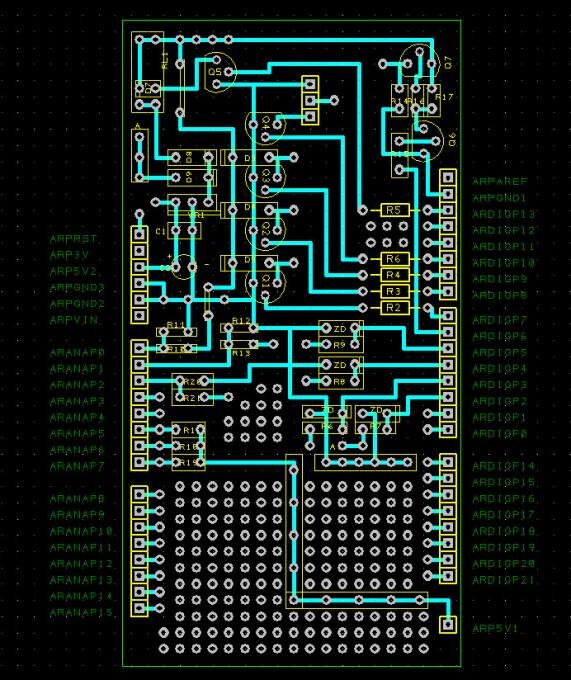

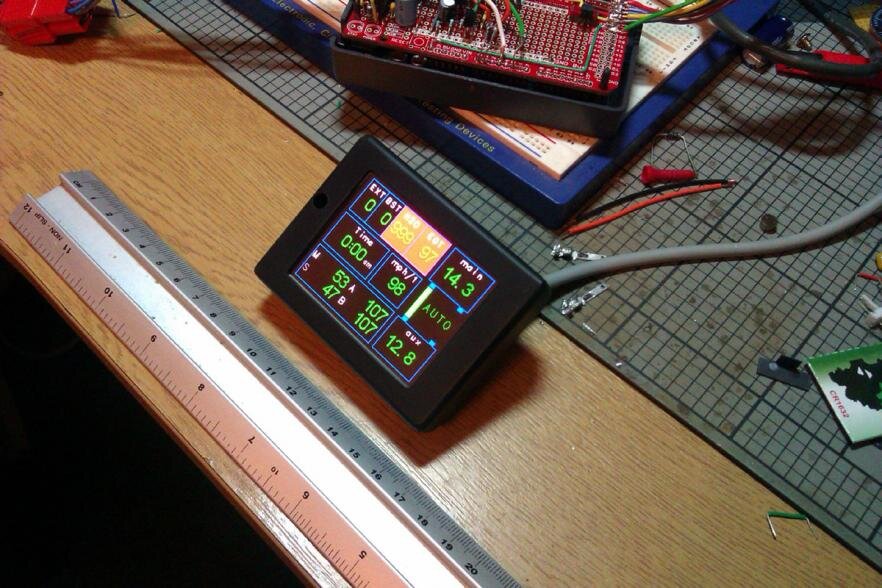

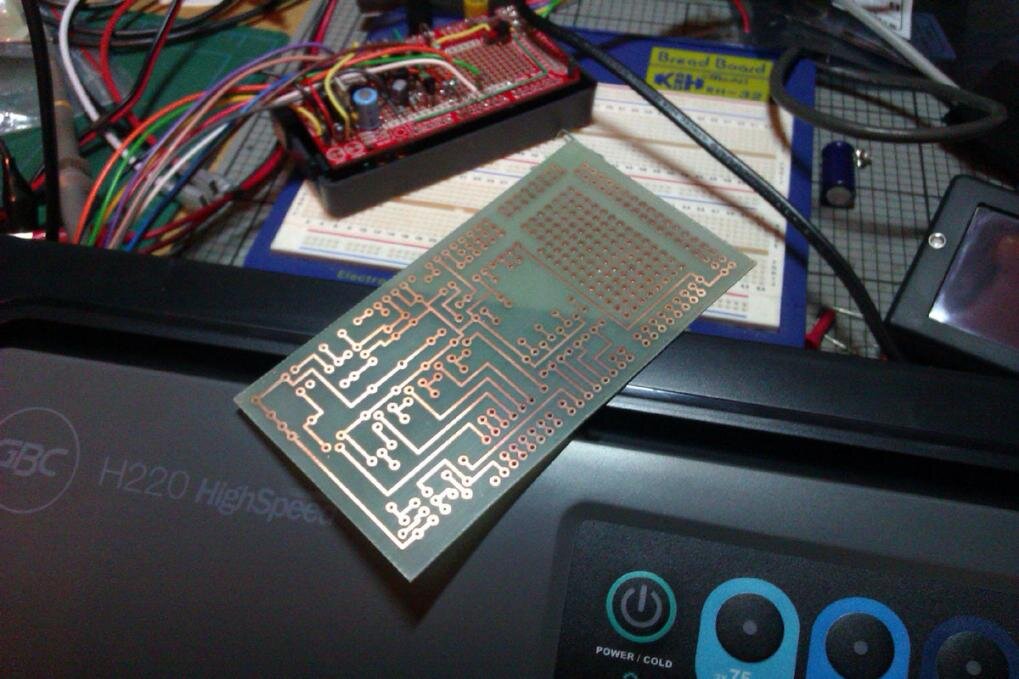

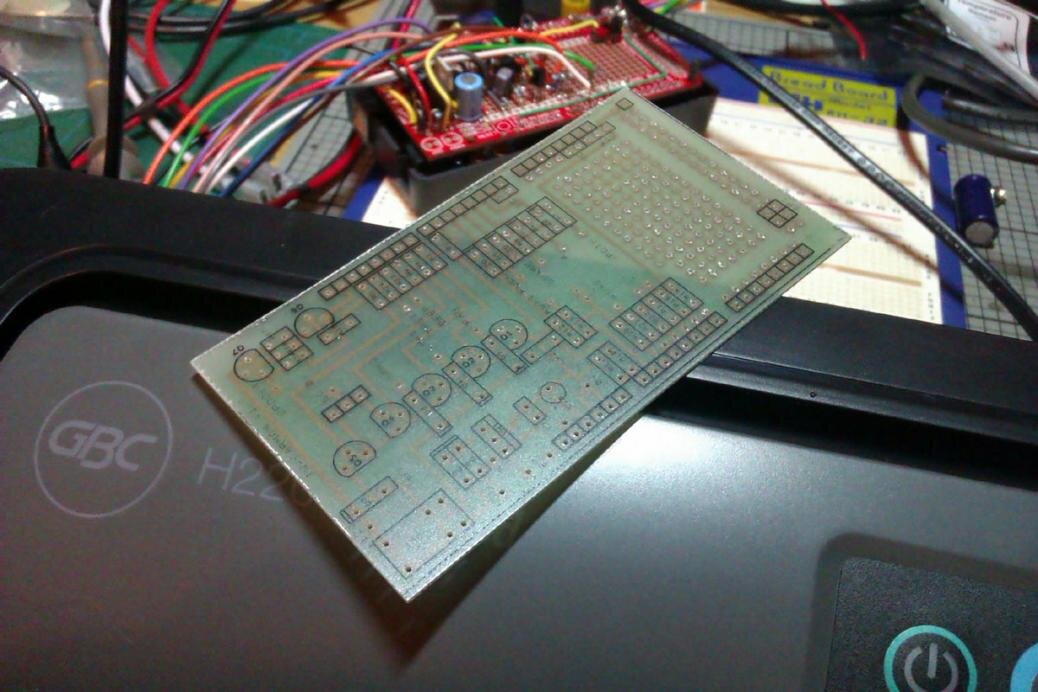

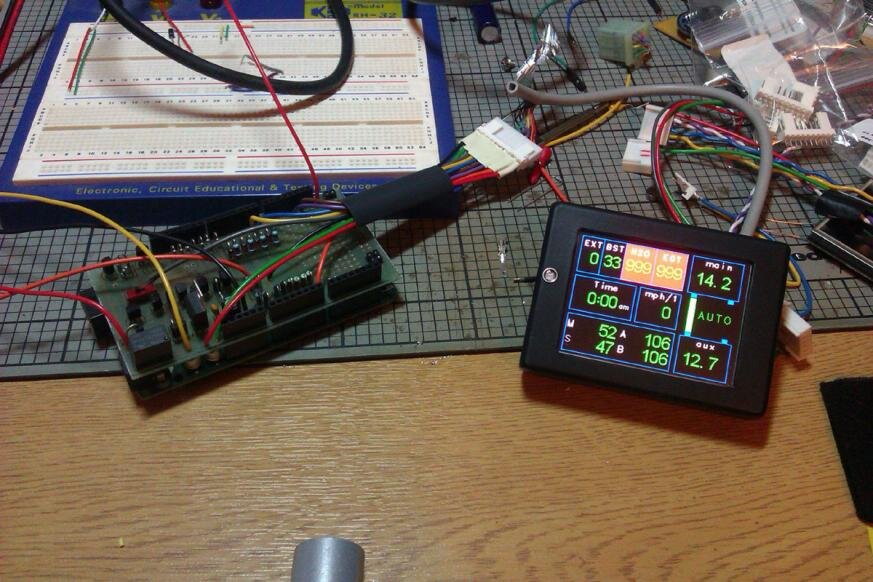

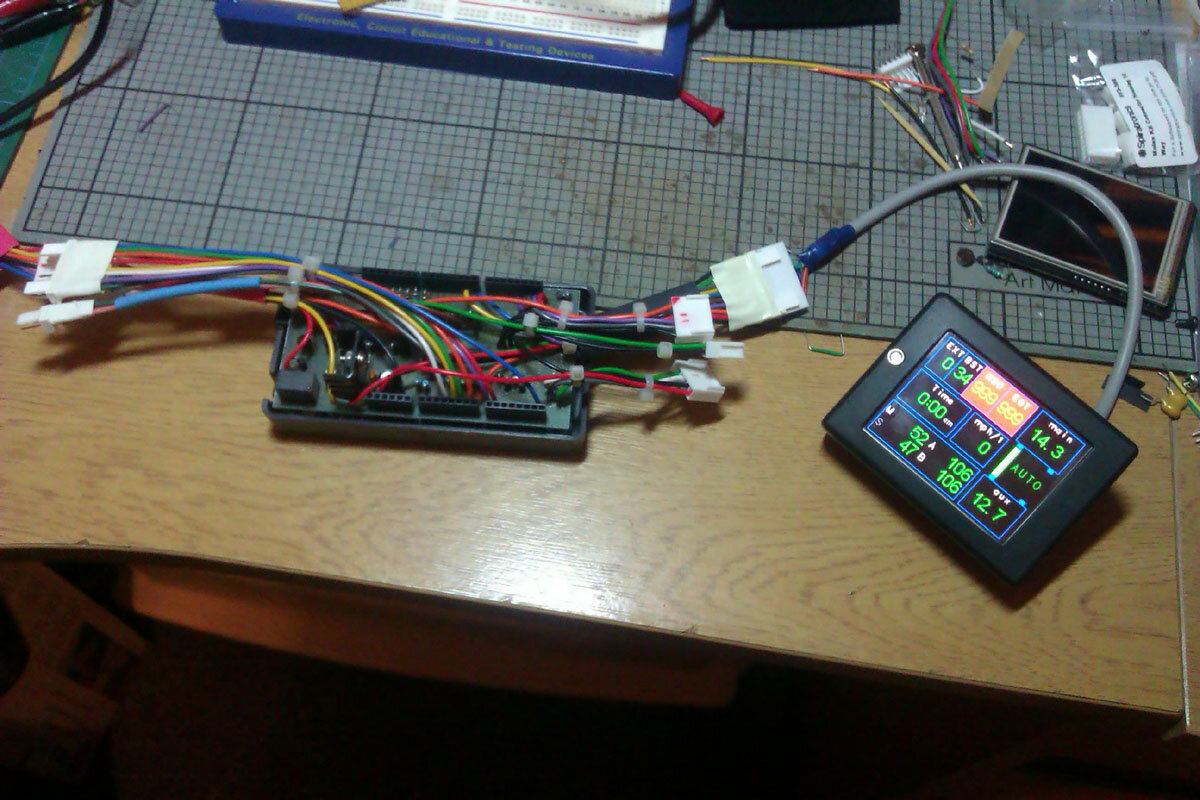

Building up an interface board for the Mk II, with slightly different power supply logic and different sensor requirements so the ATF monitoring is replaced with EGT and I've added a boost sensor and squeezed that onto the display. Still got to sort out cold junction compensation for the EGT for that to be up and running but the boost sensor input and processing is done. The petrol / lpg trips are just relabeled as Main and Sub with a feed from the sub tank switch so it will track usage from the correct tank. Bit more soldering to do and an enclosure for the display to sort out before it's ready to put in the 80.

Very nice...

Very nice...

. What about adding tire pressures?

. What about adding tire pressures?