Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

I really like your idea of the fold down table fitted to the rear wheel carrier, I thought I'd have a go at that but my rear carrier is too close to the tailgate when it's closed to fit anything in there, bugger!

It is quite tight, especially when you have to factor in the 'wobble' when the carrier is slammed shut. I have added a small rubber foam pad between the tray and the "Land Cruiser" badge in case I am a bit too rough in slamming the carrier shut. Also the upright bars have to be recessed into the carrier back plate as far as possible so as to not use up too much of that valuable space.

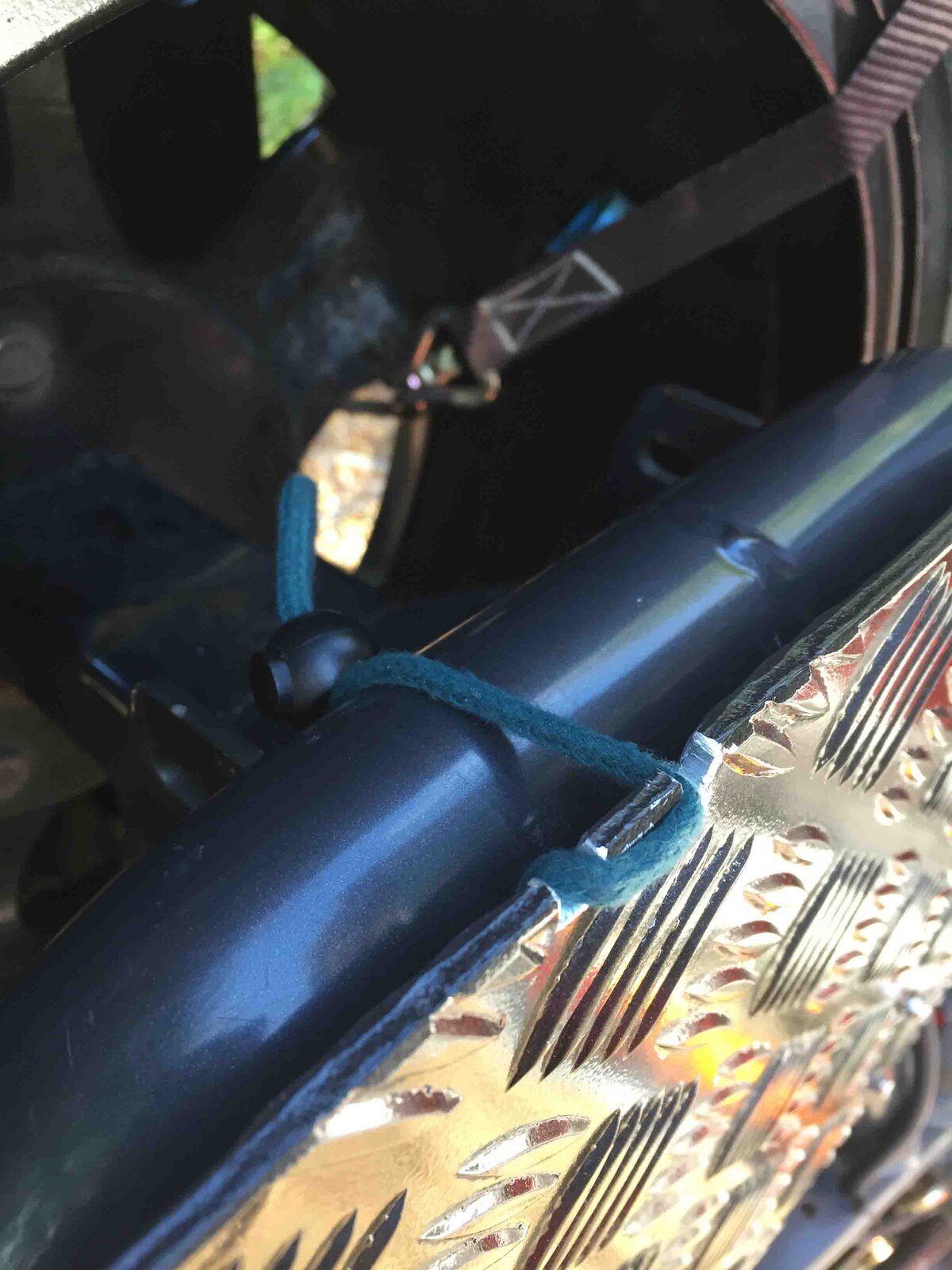

Also added a photo of the fixing mechanism to keep the tray up...a simple rope and toggle fixed into a notch on the plate

Attachments

105Aus

New Member

- Joined

- Dec 30, 2014

- Messages

- 38

- Country Flag

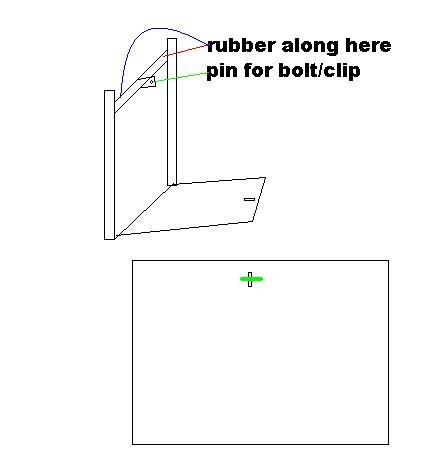

With mounting your table in the upright poisition maybe look at something like putting an extra bit of ally pipe between the cuttent 2 and weld a 25x10mm bit of flatplate with a hole drilled out and then notch out a 10mmx3mm(plate width) hole in the table and use some sponge tape or rubber along the horizontal bar to stop vibrations?

ill draw a picture haha

ill draw a picture haha

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

With mounting your table in the upright poisition maybe look at something like putting an extra bit of ally pipe between the cuttent 2 and weld a 25x10mm bit of flatplate with a hole drilled out and then notch out a 10mmx3mm(plate width) hole in the table and use some sponge tape or rubber along the horizontal bar to stop vibrations?

ill draw a picture haha

Yes a picture will help......

Don't like the adverts? Click here to remove them

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

My tray doesn't rattle.....if it did I would put a piece of rubber sheet/inner tube onto the wheel carrier mounting cross bar where the toggle cord now mounts to..... The toggle cord is my final solution but I did consider a tailgate latch type of closure as you suggest - quite neat but there is not that much room there and I had visions of forgetting to close the latch and punching a hole in the tailgate when I shut the carrier. On my design I allowed for the drop down table to be able to be slid down so that its top edge sits near the cross tube of the carrier. This adjustment up/down also allowed adjustment to clear the drawers/tailgate and adjust for my girlfriend's height as she is quite petite.

I don't weld so I am a bit limited on what I can achieve......perhaps I should do so again

I don't weld so I am a bit limited on what I can achieve......perhaps I should do so again

105Aus

New Member

- Joined

- Dec 30, 2014

- Messages

- 38

- Country Flag

Ah yep sorry i didnt see the post of the picture between your tailgate till just now, pretty tight tolerance

I like the idea of having a drop down table on the back of the carrier, when i eventually get my carrier fitted ill have to make a similar table.

I cant weld alloy, but co workers can so whenever i need alloy welded they're always helpful

I like the idea of having a drop down table on the back of the carrier, when i eventually get my carrier fitted ill have to make a similar table.

I cant weld alloy, but co workers can so whenever i need alloy welded they're always helpful

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

Ah yep sorry i didnt see the post of the picture between your tailgate till just now, pretty tight tolerance

I like the idea of having a drop down table on the back of the carrier, when i eventually get my carrier fitted ill have to make a similar table.

I cant weld alloy, but co workers can so whenever i need alloy welded they're always helpful

I did a few weeks training many years ago but never used the skills since.....I'd be starting from scratch. In the meantime I improvise

SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

Back from our trip of North Americas and the dust has settled. Time now to provide an update of what worked and more importantly what didn't work so well. 35000 miles of which 7000 on dirt and plenty of pot holes. Coped with temps up to 49C without issue.

The good news is that there were no major mechanical failures - just a sticky rear brake slide that caused the pads on that wheel to wear a bit faster......in fact down to the metal....oops. High pad wear was missed by Toyota Service centre in the US.

The major items for attention are/were:

Insufficient leisure battery capacity for running fridge/ancils in 40C desert heat. 2nd 100Ah leisure (3rd battery on vehicle) added

Insufficient solar panel capacity to maintain leisure battery charge in hot weather and long camp periods. Extra 100W added to 80W that we went with

Too much background current running the battery down when camped. Put power switch onto iPod/Digital radio interface that sometimes stays powered. Add switch to USB charging circuits to isolate from camp power circuits when not in use

Roof tent optimisation - add snap-buckles (like on back packs) instead of the cam style /webbing grips - easier and quicker to tighten down the RTT cover straps. Also added Velcro pads to grip the RTT mattress to stop it moving when getting the tent out and jamming the hinge.

DRL's - eventually a 1/3rd of the LEDs on each burned out after a year of more or less constant use. DRL voltage sensing circuits (auto-on) also troublesome and sometimes didn't put the lights on. Entire system removed as not required for Africa

Cold starting air intake heater reinstated as got fed up with embarrassing puff of blue smoke on campsites

Rear diff lock actuator corroded and failed - replaced

Knarled ancillary belt adjusting bolt replaced

Precautionary replacements due to wear and tear:

NSF CV and drive flange - some play

Worn lower control arm ball joint - the only one left to do now done

rear anti-roll bar link bushes replaced

Partial replacement of ATF

Replaced all disks as worn down to limit or close to limit (and 1 rear deeply scored and one had a slight vibration on braking)

Grumbly front wheel bearings replaced

Normal Service items plus Valve clearances adjusted.

So pretty pleased with all that on the whole. We have been ultra-cautious with worn items as we don't want to break down in the Kalahari, or be surrounded by lions

The good news is that there were no major mechanical failures - just a sticky rear brake slide that caused the pads on that wheel to wear a bit faster......in fact down to the metal....oops. High pad wear was missed by Toyota Service centre in the US.

The major items for attention are/were:

Insufficient leisure battery capacity for running fridge/ancils in 40C desert heat. 2nd 100Ah leisure (3rd battery on vehicle) added

Insufficient solar panel capacity to maintain leisure battery charge in hot weather and long camp periods. Extra 100W added to 80W that we went with

Too much background current running the battery down when camped. Put power switch onto iPod/Digital radio interface that sometimes stays powered. Add switch to USB charging circuits to isolate from camp power circuits when not in use

Roof tent optimisation - add snap-buckles (like on back packs) instead of the cam style /webbing grips - easier and quicker to tighten down the RTT cover straps. Also added Velcro pads to grip the RTT mattress to stop it moving when getting the tent out and jamming the hinge.

DRL's - eventually a 1/3rd of the LEDs on each burned out after a year of more or less constant use. DRL voltage sensing circuits (auto-on) also troublesome and sometimes didn't put the lights on. Entire system removed as not required for Africa

Cold starting air intake heater reinstated as got fed up with embarrassing puff of blue smoke on campsites

Rear diff lock actuator corroded and failed - replaced

Knarled ancillary belt adjusting bolt replaced

Precautionary replacements due to wear and tear:

NSF CV and drive flange - some play

Worn lower control arm ball joint - the only one left to do now done

rear anti-roll bar link bushes replaced

Partial replacement of ATF

Replaced all disks as worn down to limit or close to limit (and 1 rear deeply scored and one had a slight vibration on braking)

Grumbly front wheel bearings replaced

Normal Service items plus Valve clearances adjusted.

So pretty pleased with all that on the whole. We have been ultra-cautious with worn items as we don't want to break down in the Kalahari, or be surrounded by lions

Similar threads

- Replies

- 9

- Views

- 2K