SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

Installed the CB today. Mounted discretely down the side of the freezer centre console. The unit is demountable as some countries (like Morocco) don't like CBs and thus a good idea to remove at borders and the like. Also mounted up a pair of speakers above the front passenger seats so I can hear the CB above the sound of music, road noise the sat nag etc

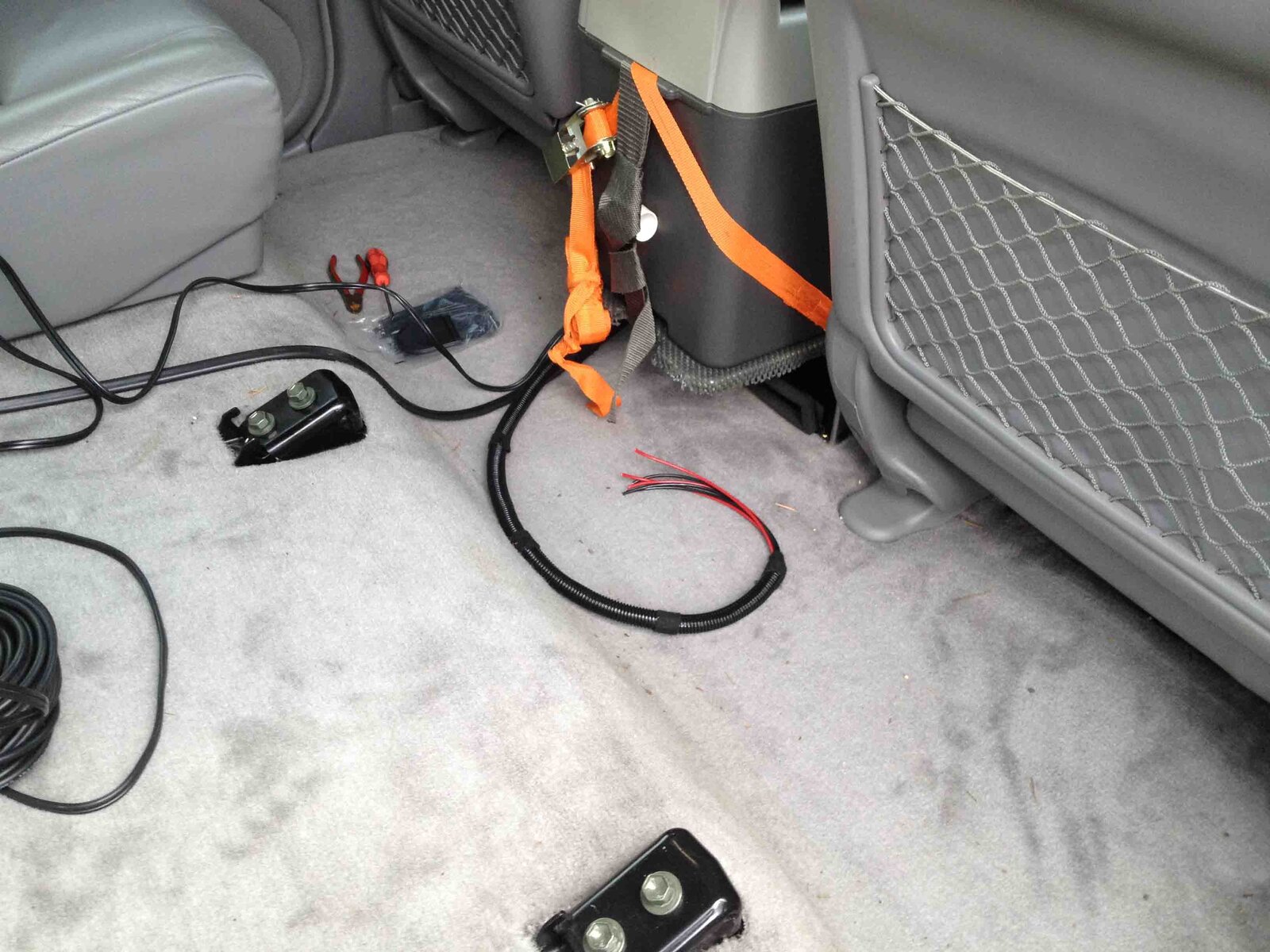

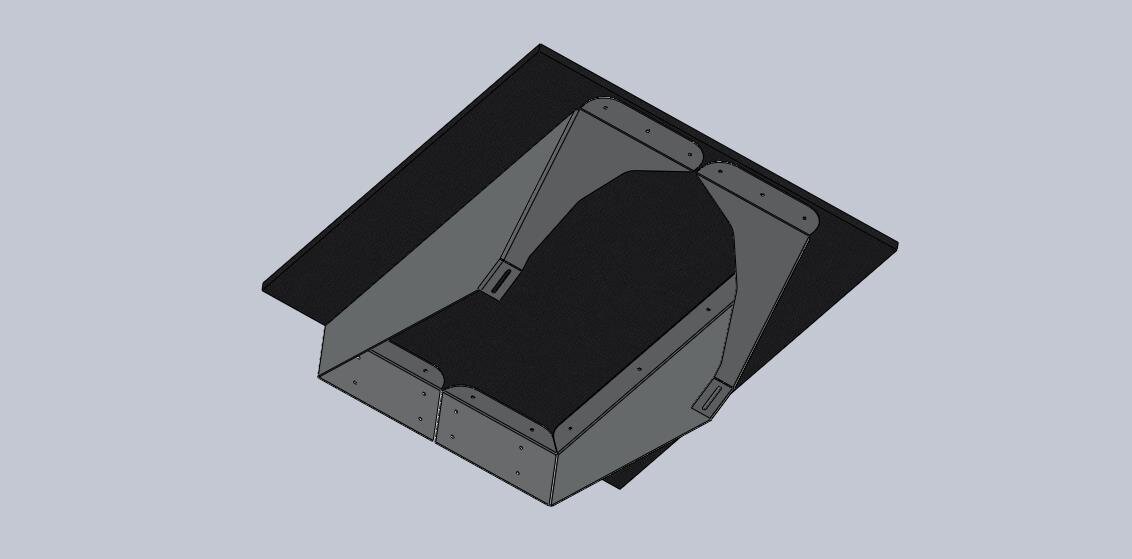

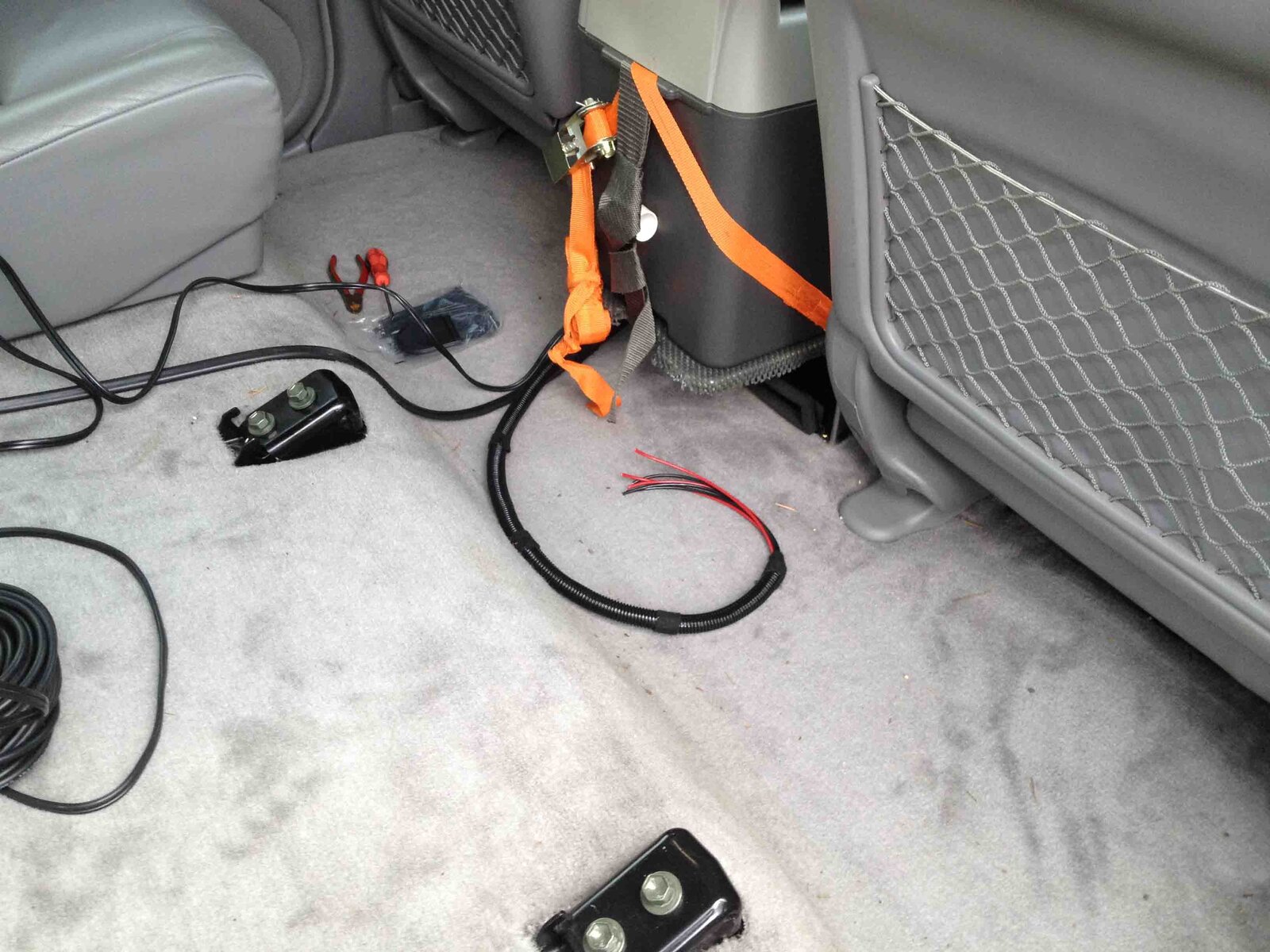

Also shown are the 12v tails from the relay switched permanent 12v. All the 12v sockets in the car are switched so that they can remain live at all times or all completely isolated. The 100A relay and bluesea fuse board feeds two 20A circuits to the area behind the front seats (1 for the fridge and 1 for high power hand tools (12v hair dryer ) plus a heavy gauge circuit to the rear of the truck (long run so wanted to reduce voltage drop) for general camp power, powering the lap-top etc. The front 2x console sockets are fed from same.

) plus a heavy gauge circuit to the rear of the truck (long run so wanted to reduce voltage drop) for general camp power, powering the lap-top etc. The front 2x console sockets are fed from same.

The 12v tails will be finished with Anderson connectors and mounted under the extended load deck where the middle row seats used to be

Also shown are the 12v tails from the relay switched permanent 12v. All the 12v sockets in the car are switched so that they can remain live at all times or all completely isolated. The 100A relay and bluesea fuse board feeds two 20A circuits to the area behind the front seats (1 for the fridge and 1 for high power hand tools (12v hair dryer

The 12v tails will be finished with Anderson connectors and mounted under the extended load deck where the middle row seats used to be