Jente

Active Member

- Joined

- Jun 10, 2014

- Messages

- 83

- Country Flag

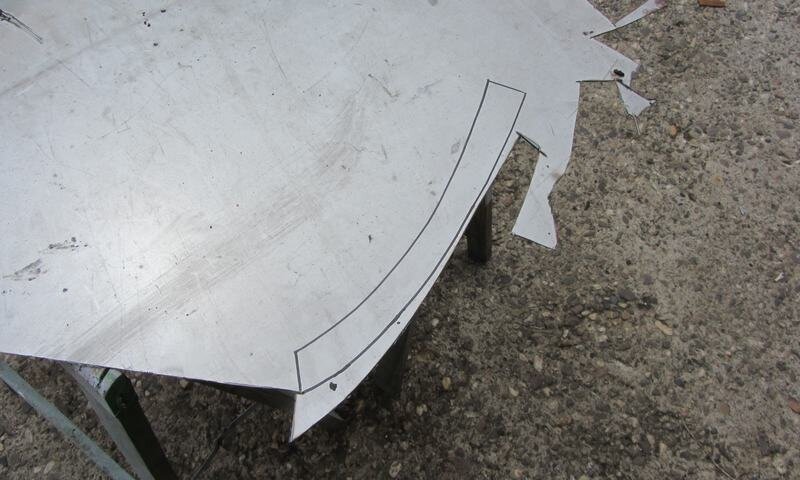

After most of the doors were done, I started getting the Left front fender off.

Almost the entire wheel arch was rotten away, as well as the part in front of the sill.

After watching a DVD about an old bloke showing original sheet metal technics, I got inspired and decided to give it a go.

Keep in mind, the goal for this project is not to get in complete original condition. Rust prevention is the key thing.

If some of the original line differ by a few millimeter, we'll just call it a one-off design by me

Rotten area, in front of the sill. Remaining steel was too thin to leave it like that, but usable to catch it's original shape.

Exept the first few pics in this threas, all pictures have been taken with my phone. On the phone the quality is good, but having them on a bigger screen I'm a bit disappointed....

I'll get my proper camera back in the shop, and use it from now on!

With the cruiser being dry and warm, I started notice brown drips on several spots on the chassis. It looks to be coming from the inside out?

Almost the entire wheel arch was rotten away, as well as the part in front of the sill.

After watching a DVD about an old bloke showing original sheet metal technics, I got inspired and decided to give it a go.

Keep in mind, the goal for this project is not to get in complete original condition. Rust prevention is the key thing.

If some of the original line differ by a few millimeter, we'll just call it a one-off design by me

Rotten area, in front of the sill. Remaining steel was too thin to leave it like that, but usable to catch it's original shape.

Exept the first few pics in this threas, all pictures have been taken with my phone. On the phone the quality is good, but having them on a bigger screen I'm a bit disappointed....

I'll get my proper camera back in the shop, and use it from now on!

With the cruiser being dry and warm, I started notice brown drips on several spots on the chassis. It looks to be coming from the inside out?