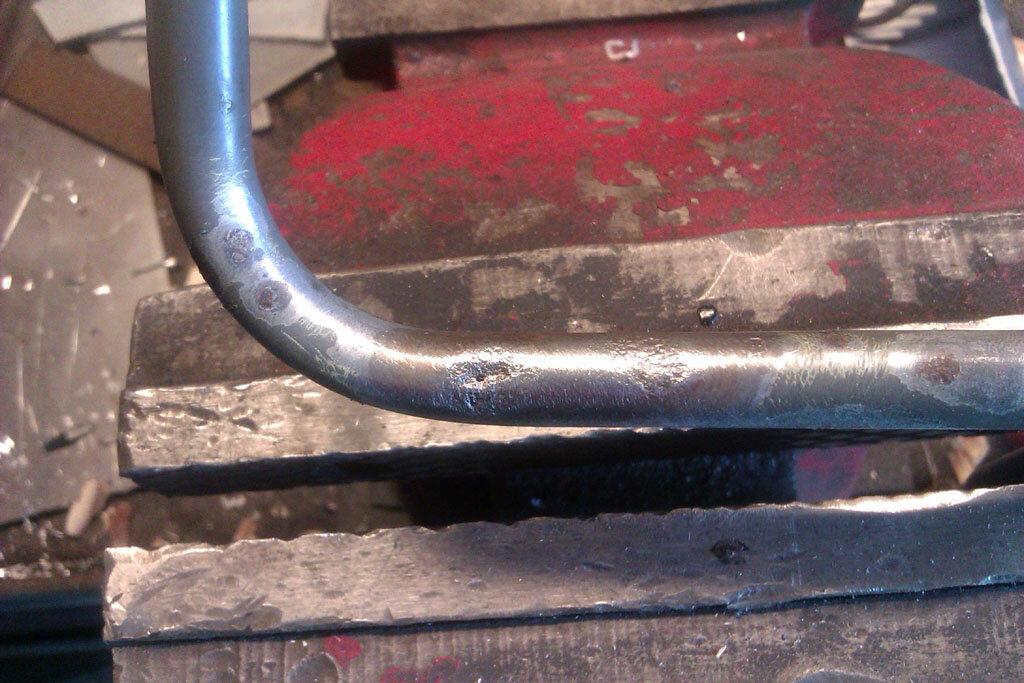

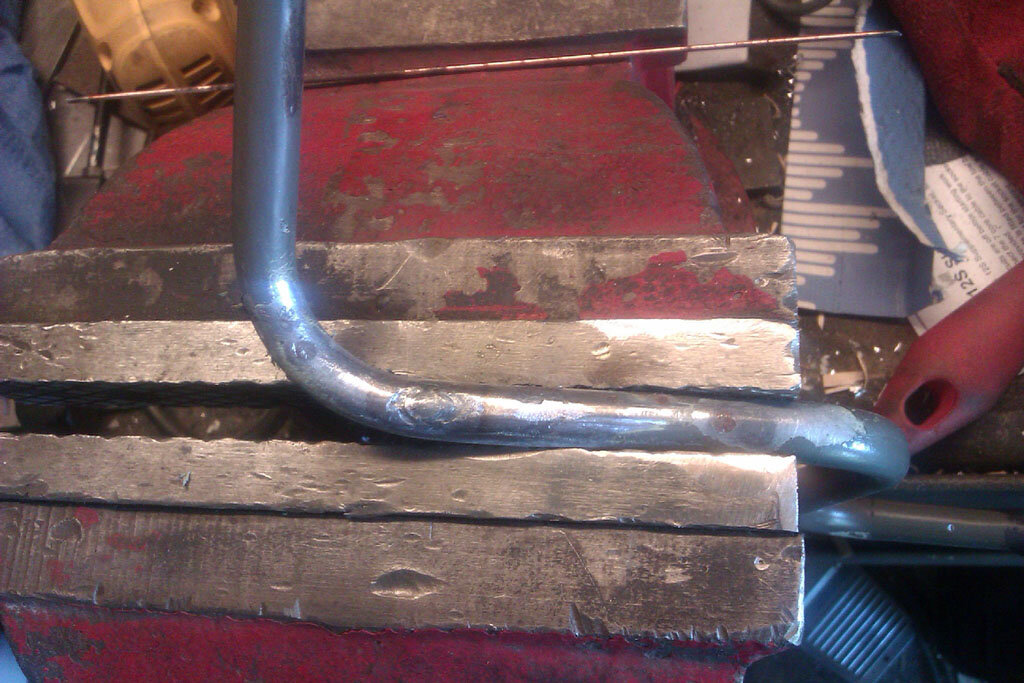

Been fiddling with the wheel carrier jobs again today. Made a mount for the number plate to put it on the wheel carrier and while I was waiting for the paint to dry I had an experiment with something to hold the wheel carrier open. Previously I've drilled a hole in the bottom casting and dropped a pin through but I wanted to try something that would stop the carrier opening too far as well as holding it open. That's not normally a problem but can be if you're in a tight space and have to keep moving the carrier out of your way because it's opened all the way. Came up with this, bit like you can buy to hold doors open, just a bit of all thread bent to hook into a hole I drilled and a small bracket to give some adjustment.

[attachment=7:2o3v993t]IMAG1028.jpg[/attachment:2o3v993t]

[attachment=6:2o3v993t]IMAG1030.jpg[/attachment:2o3v993t]

Paint dry on the number plate holder I put the lights and plate onto it

[attachment=5:2o3v993t]IMAG1041.jpg[/attachment:2o3v993t]

I'd welded a bolt onto the end of the mount and I just put a plastic spreader / spacer, washer and nut on the other side to hold it on

[attachment=4:2o3v993t]IMAG1043.jpg[/attachment:2o3v993t]

Finished up like this

[attachment=3:2o3v993t]IMAG1034.jpg[/attachment:2o3v993t]

testing

[attachment=2:2o3v993t]IMAG1052.jpg[/attachment:2o3v993t]

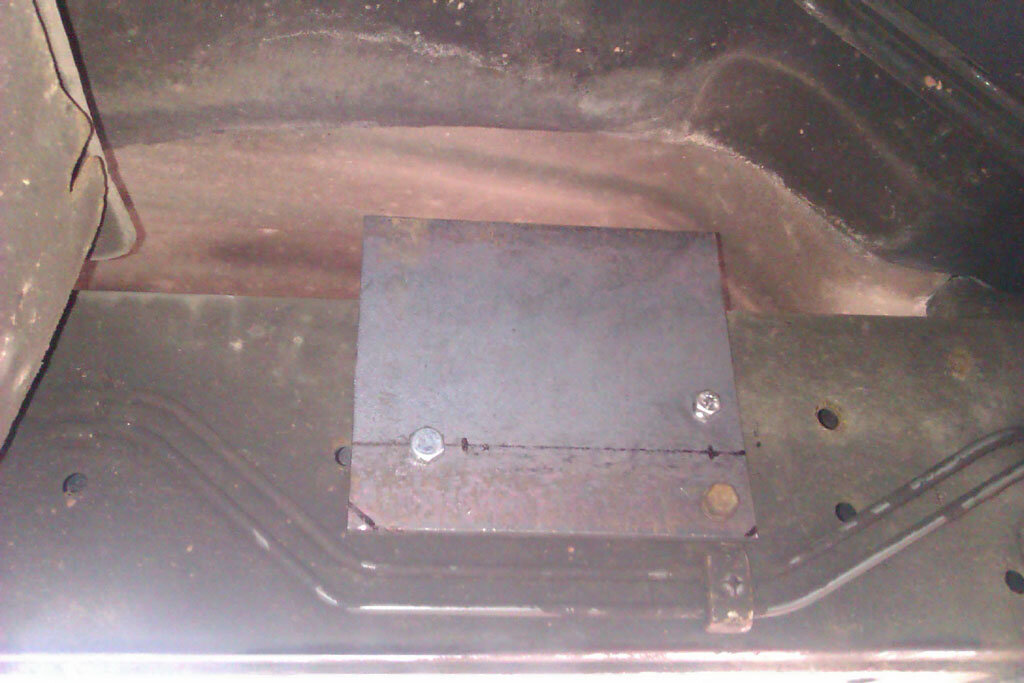

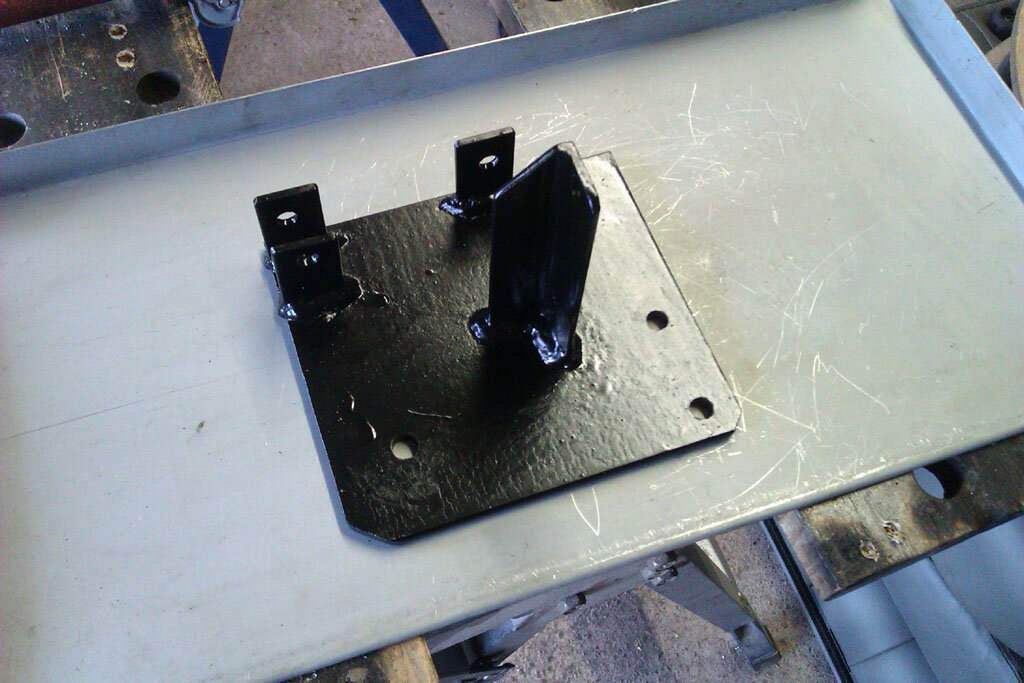

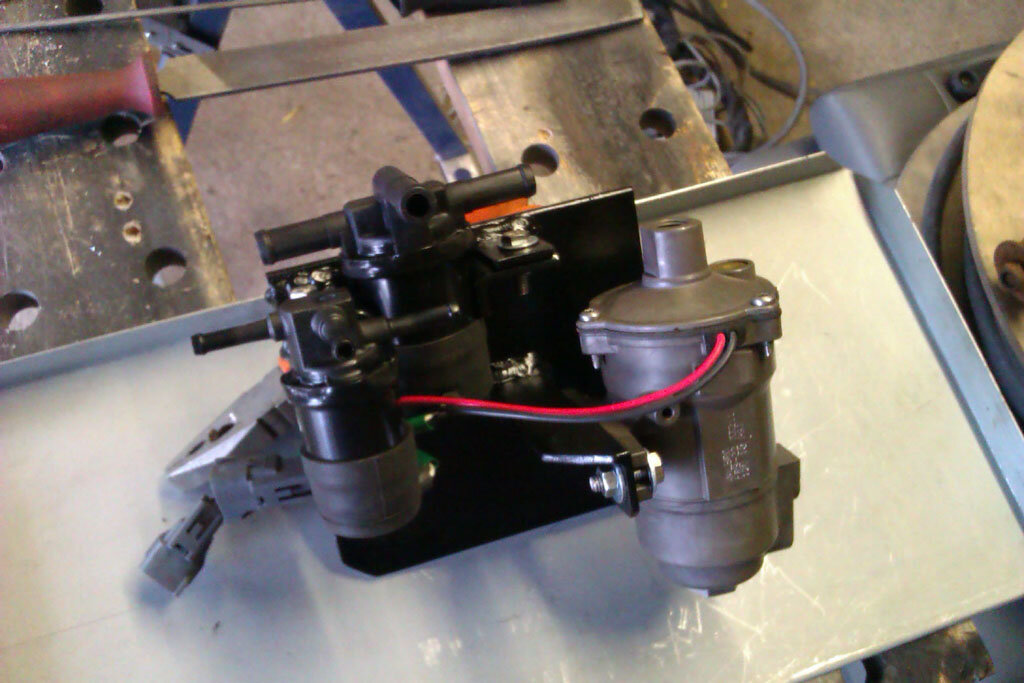

Also decided where to put the monster size compressor and sorted out wiring for that with Anderson connectors so it can be used in its hidy hole, pulled out onto the tailgate so it gets more air, or unplugged from the dedicated connection and plug the remains of the cable it came with back on and use the croc clips so it's still portable.

[attachment=1:2o3v993t]IMAG1045.jpg[/attachment:2o3v993t]

I did have to remove the bottom plate for it to fit through the gap and just left the bolts so it still sits off the floor a bit. At some point I plan to make another base for it that will fit through the hole.

[attachment=0:2o3v993t]IMAG1049.jpg[/attachment:2o3v993t]