Sway Bar.

I had been after a sway bar (or anti roll bar if your not from Australia) for a while but it was proving hard to find one as most people remove them as they limit articulation off road.

As RJ will be mainly road based with some beach driving and light off roading, I decided I wanted one for the improved road handling.

Well I finally got lucky and found one.

Stripped it down ready for paint.

Got it outside with a load of other parts that needed cleaning up with a wire wheel in the angle grinder.

I had intended to get all these bits shot blasted then either electro plated or powder coated but as I'm struggling to find places up here that are willing to work for a fair price and not rip you off, I figured I would just clean them up and paint them myself.

Did these 3 and they actually came up pretty good.

Gave them a coat of this rust killer and primer in one. Not cheap stuff but I'm impressed with it so far.

Followed by 2 coats of this black enamel.

Spare Wheel Mount

While I was cleaning up the spare wheel mount and getting it ready for paint I found a crack in it.

Cleaned it up better using a wire wheel in the drill.

And then found 2 other cracks!

Fusion welded them back together with the TIG.

And gave it a couple of coats of paint too.

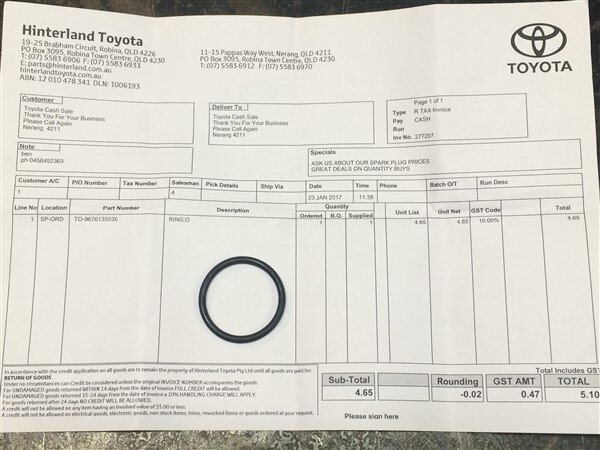

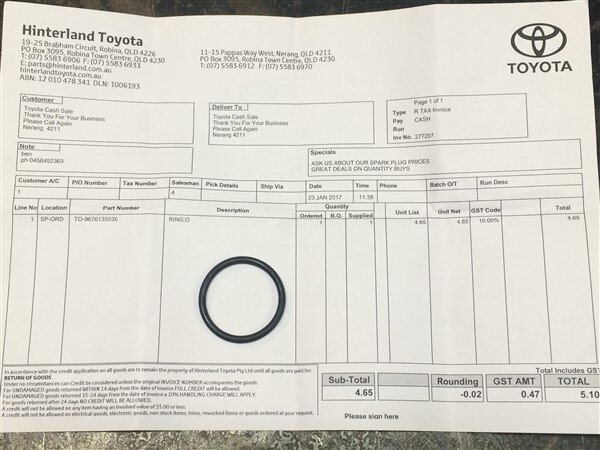

Thermostat Housing O Ring

Thermostat Housing O Ring

The O ring I ordered from my local Toyota dealer arrived on Monday.

Which meant I could bolt the housing back on.

Interior

Interior

I stripped the interior out a little bit this morning.

Pulled the front seats out.

Followed by the vinyl flooring, which because it had been fitted without any underlay its badly damaged and split.

The floor pan isnt too bad for a 31 year old car.

Theres a couple of tiny holes that need repairing.

I wanted to remove the access panel off the top of transmission tunnel next.

That will make it easier to connect the transfercase stick and fit the new rubber boot to the top of the gearbox as the old one was split.

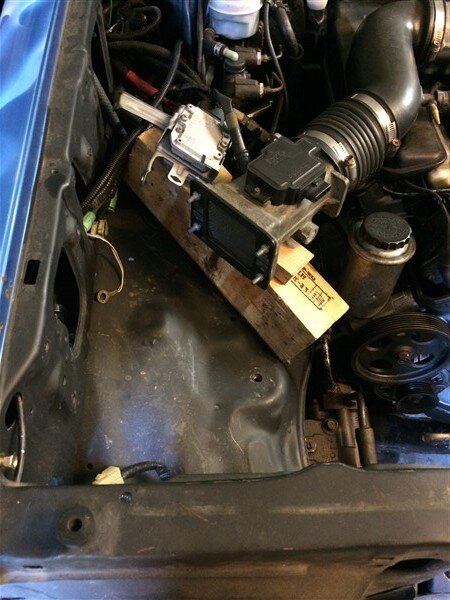

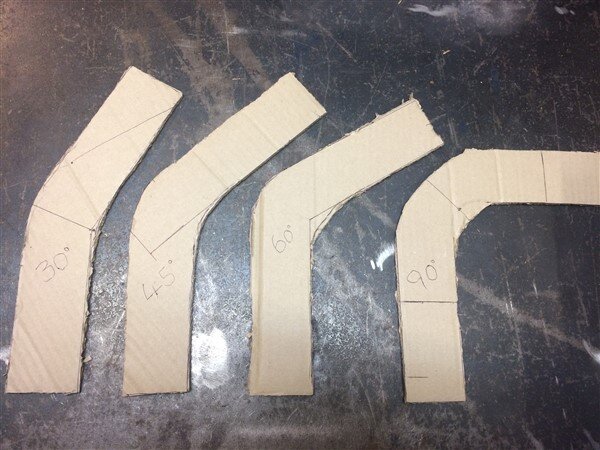

Radiator Hoses

Radiator Hoses

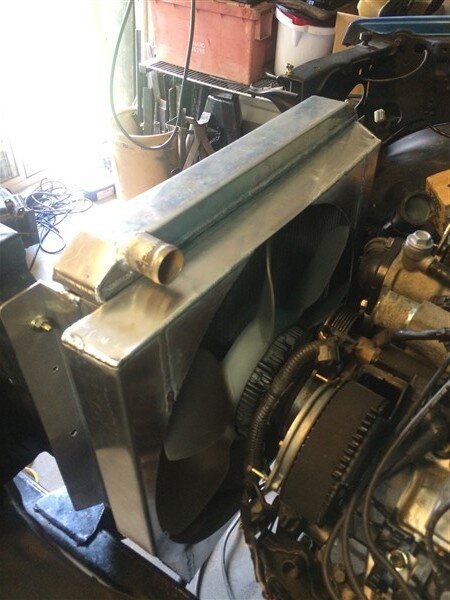

I've been looking at connecting the rad up to the engine.

The standard Lexus hoses seemed like a good starting point.

Top hose wont work though sadly.

And the bottom one isnt really long enough at the top.

Cut some out of the top one.

Until I got it fitting nicely.

Taped it together.

And that is my sample hose, all I need to do now is take it to my local Repco/Bursons etc. and look through the hose boxes.

Most people who do this conversion seem to make the rad hoses up using multiple universal silicon bends connected with joiners and lots of hose clamps, but I'd rather just use one hose top and bottom if possible and keep it nice and neat and simple.

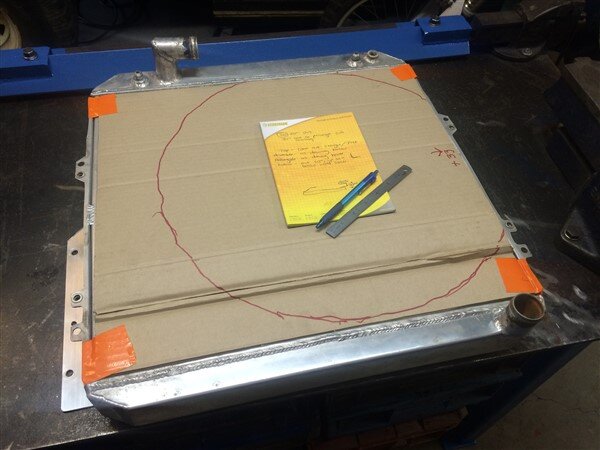

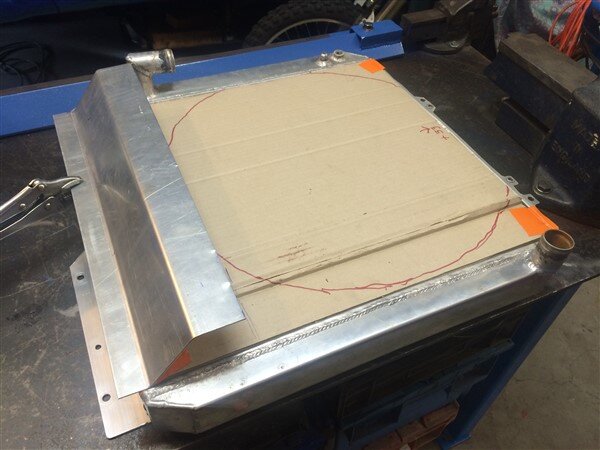

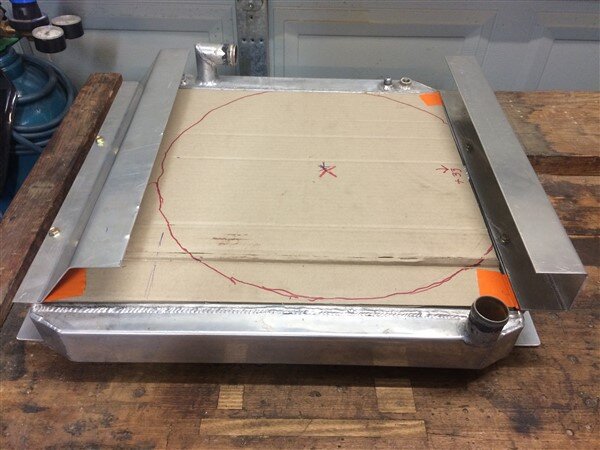

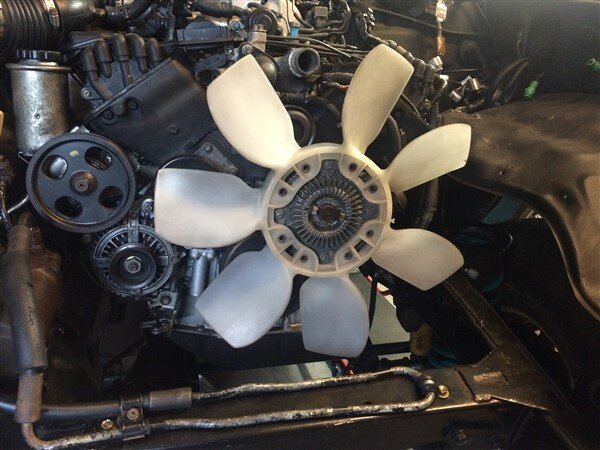

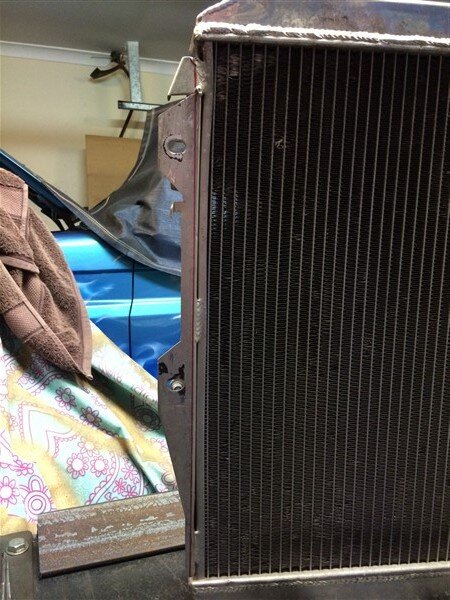

Radiator Cowl

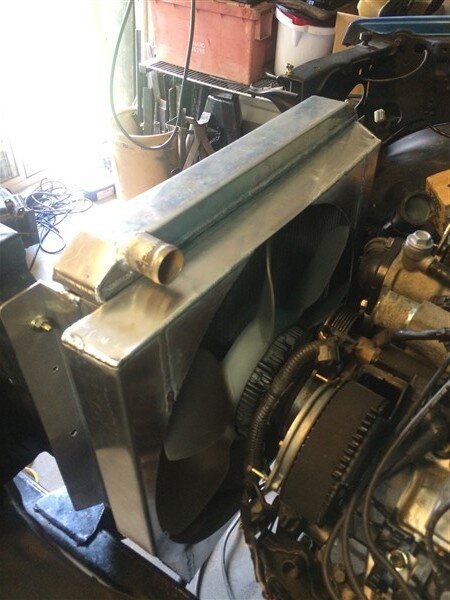

Radiator Cowl

A rad cowl is extremely important, I found without one fitted to my other 70, it overheats!

So I needed to make one to help channel the cool air through the rad.

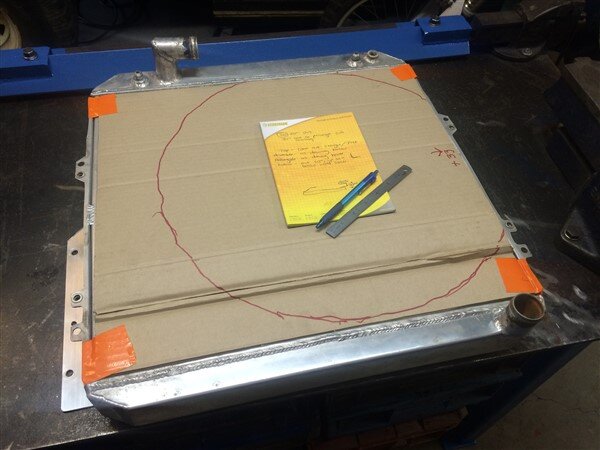

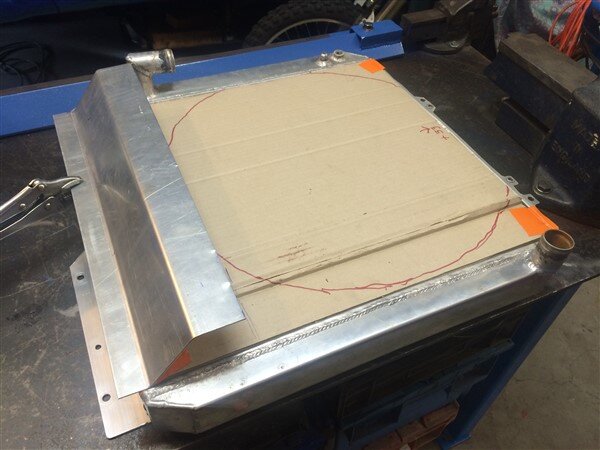

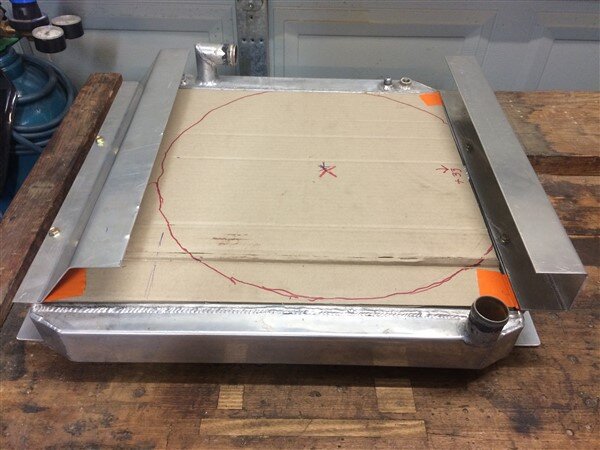

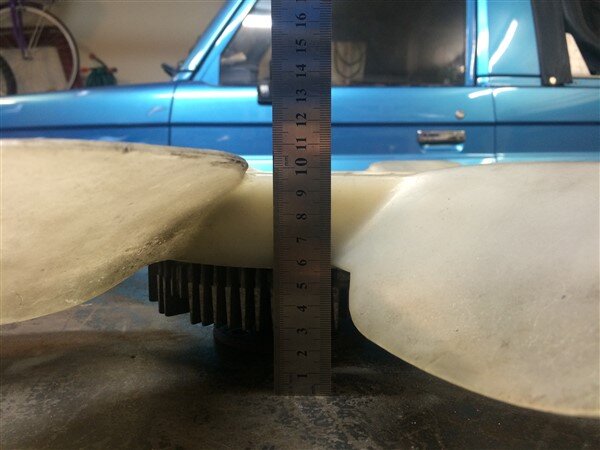

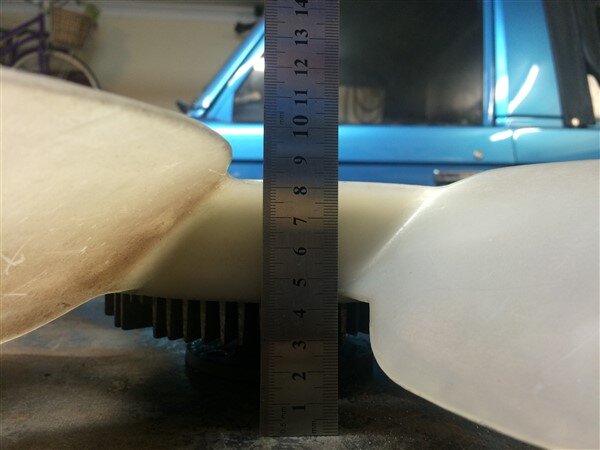

Took some measurements and pulled the rad back off.

Cut some 2mm alluminium sheet.

Got it into the folder.

First bend.

To 45 degrees.

Second 45 degree bend.

Resulted in this.

Clamped in position.

Folded some more alluminium for the other side.

Drilled and bolted both pieces on.

Cut and folded some more.

Cut one last strip.

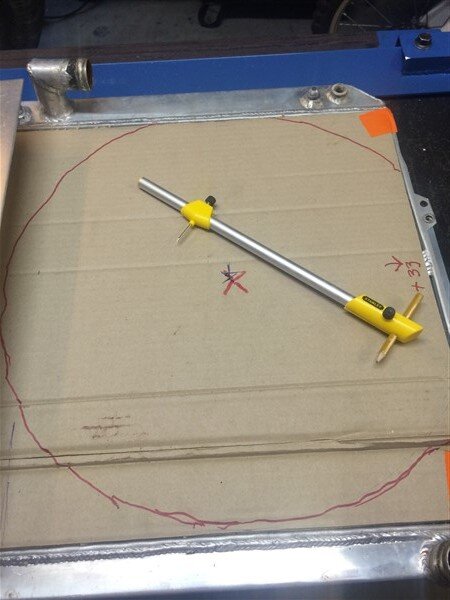

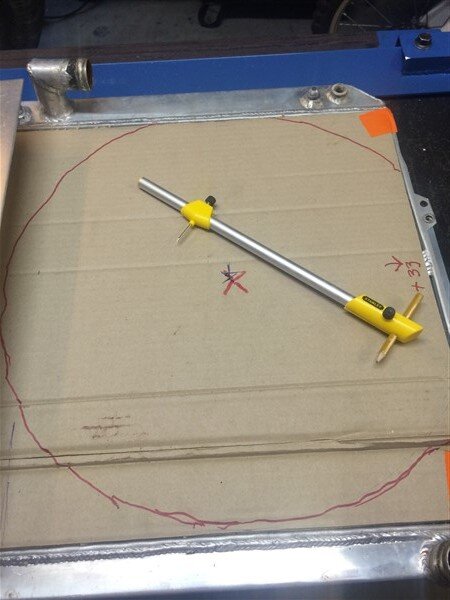

Using my big Stanley compass, I marked what would need cutting out, using a center point I worked out from my pen marks on the cardboard.

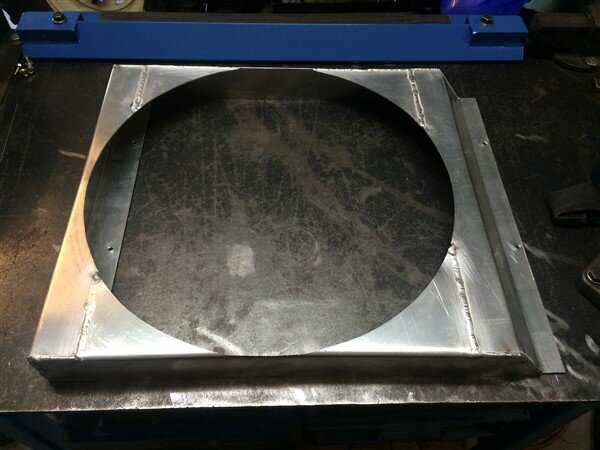

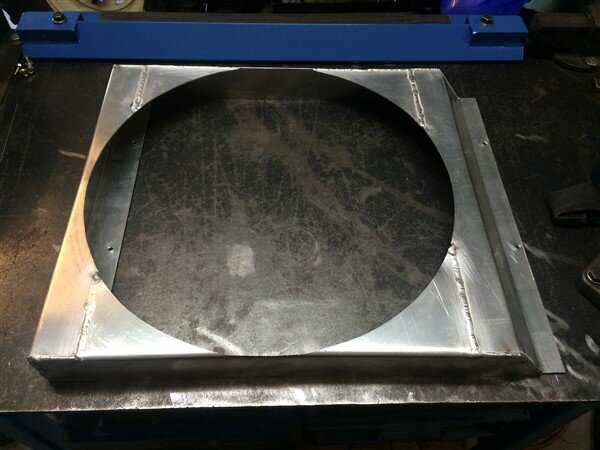

Cut all the sections out.

Clamped and welded it all together.

All done, or so I thought.

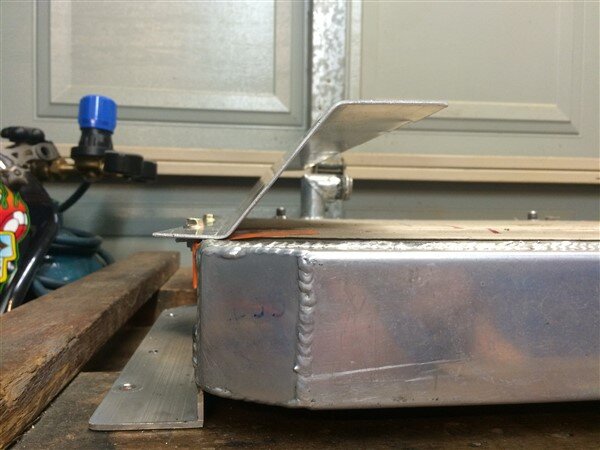

Went to fit it and found it was hitting the chassis rail on the passenger side.

Chassis rail is marked in red.

Cut a section off.

Test fitted it.

Cut and welded in a strip of alluminium to cap it off and get some strength back into the structure.

Bottom Radiator Outlet Modification

Bottom Radiator Outlet Modification

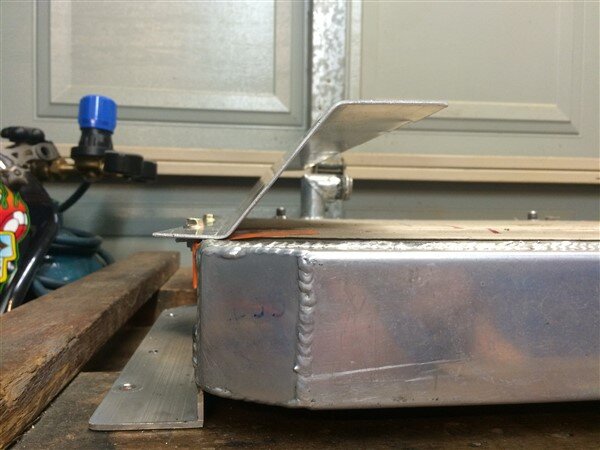

I needed to change the bottom outlet for the bottom rad hose.

2 hacksaw cuts later.

Clamped it in position and welded it on.

New Parts for the build

New Parts for the build

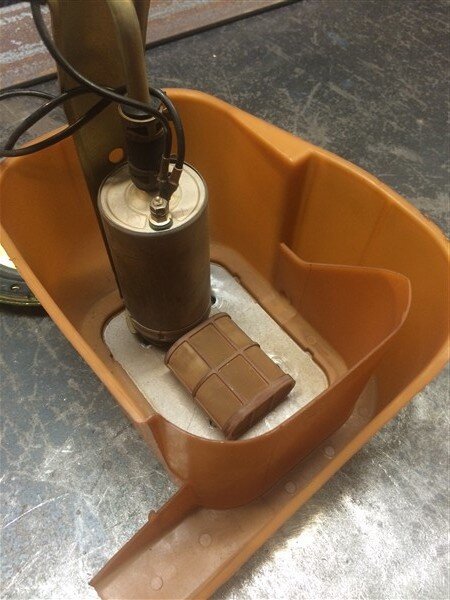

I had 3 deliveries today for the build!

The alluminium radiator neck for the top of the rad has come and so can be welded on next.

And 2 orders from Amayama which is mainly engine parts and pieces of interior trim that I was missing.

I've ordered some NGK Iridium spark plugs from the UK (much cheaper than getting them in Australia) and once they are here the engine can be completely put back together.

Parts I still need to buy:

-Stainless steel exhaust parts (mandrel bends, flexies, collector cone to make 2 pipes into 1, flanges and tube).

-A new battery, maybe an Optima.

-5 x 33" x 12.5 x 16 BFG KM2's.

-Airfilter/induction kit.

-Vinyl flooring and underlay.

Oh I almost forgot................................

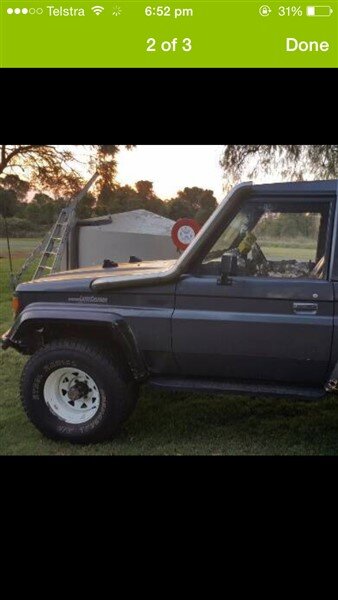

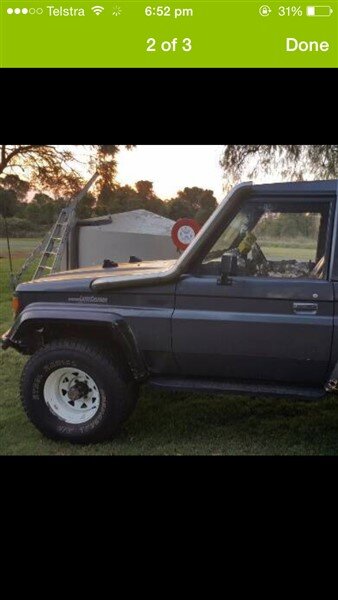

I almost bought another soft top RJ70 this week.

I went and looked at this:

But all I really wanted from it was the super rare, genuine Toyota fiber glass hard top.

So I decided not to buy it, had we been in a position where we had some land and wernt planning on moving every year for the next 5-10 years then at that price I would have just bought it and parked it up in a shed.

)

)