Rob Cowell

Well-Known Member

- Joined

- Nov 15, 2011

- Messages

- 1,643

- Country Flag

Has anyone changed their 120 rack bushes? Got through 2 sets on my old 90, and plenty of threads about those, but even PP seems devoid of 120 bushes going.

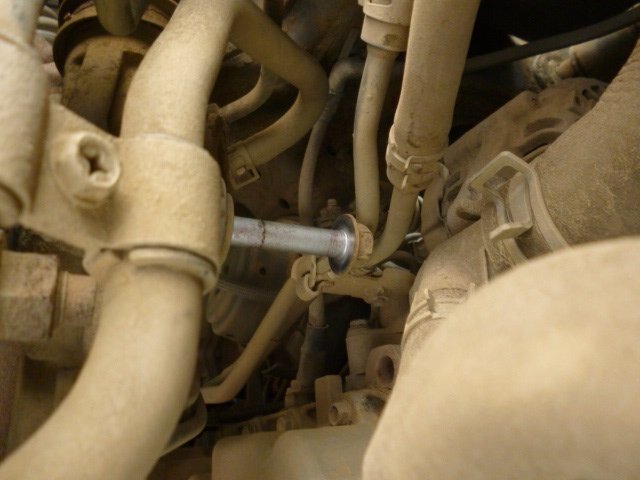

Ive got a 2005 LC3, 95K miles. Drives some rough tracks in daily use. Noticed last week that coming off the throttle on the motorway caused a small veer to the right. Today noticed on some twisty roads something slightly "rolly" (more rolly than usual!) about the ride. Have had a lay underneath with the bash plates still on and had Mrs Cowell turn the wheel while I held the mounting points for the rack. There does seem to be a very small bit of movement between rack and chassis, so I assume bushes. I can see Roughtrax stock replacements. Just can't see anywhere what's involved in replacing them. Did the 90 a couple of times so I reckon I'm up to it! But always nice to see someone else's attempt in writing first.

Ive got a 2005 LC3, 95K miles. Drives some rough tracks in daily use. Noticed last week that coming off the throttle on the motorway caused a small veer to the right. Today noticed on some twisty roads something slightly "rolly" (more rolly than usual!) about the ride. Have had a lay underneath with the bash plates still on and had Mrs Cowell turn the wheel while I held the mounting points for the rack. There does seem to be a very small bit of movement between rack and chassis, so I assume bushes. I can see Roughtrax stock replacements. Just can't see anywhere what's involved in replacing them. Did the 90 a couple of times so I reckon I'm up to it! But always nice to see someone else's attempt in writing first.

That does look like a nasty job to do. I hope it ends soon and well.

That does look like a nasty job to do. I hope it ends soon and well.