- Joined

- May 13, 2019

- Messages

- 832

- Country Flag

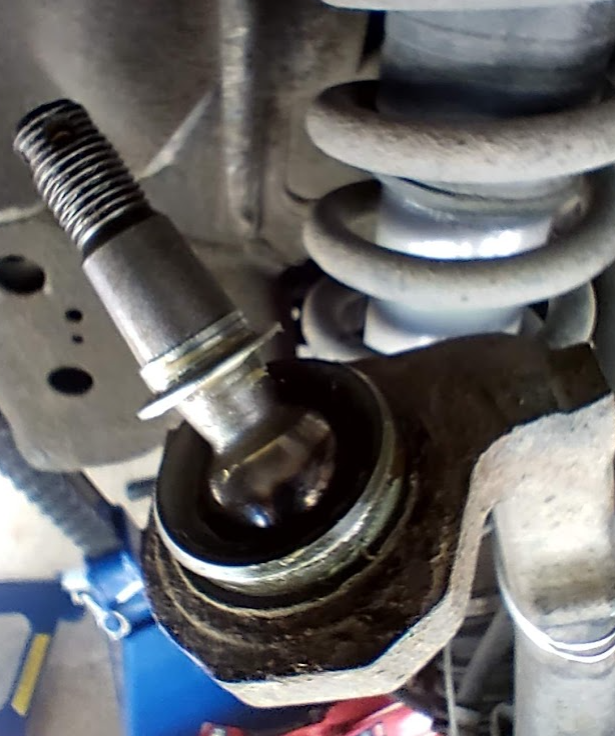

So I was looking around today and found a split in an upper ball joint boot. Looks OK inside and it's just a narrow slit at the moment plus I don't think it's been there long as I last inspected them 6 months ago.

Anyway looked in the trusty Haynes manual and replacement of the UBJ (or UBJ boot) seems simple, looks like you unbolt and split the UBJ off the upper control arm then the whole knuckle droops down. Doesn't look like you need to remove any other suspension components or half-shaft etc.

Surely it can't be that simple? Has anyone done it and if so what kind of splitter did you use?

LBJs have been done already, not sure if the UBJs are original. Car has 390,000km on the clock.

Anyway looked in the trusty Haynes manual and replacement of the UBJ (or UBJ boot) seems simple, looks like you unbolt and split the UBJ off the upper control arm then the whole knuckle droops down. Doesn't look like you need to remove any other suspension components or half-shaft etc.

Surely it can't be that simple? Has anyone done it and if so what kind of splitter did you use?

LBJs have been done already, not sure if the UBJs are original. Car has 390,000km on the clock.

.

.