A couple of days ago I replaced the front ARB bushes and drop links on the 100.

Whoever designed this thing deserves a prize - the bush retaining brackets are directly above the torsion bars so only a flat spanner will fit the lower bolt and the angles are such that one can't get access from above for the upper one as the lower wishbone is in the way.

Naturally one head sheared off and it took two hours to get the remains of the shaft out with heat and my smallest mole grip

.

All done now, but I haven't taken any photos of the installation yet.

They needed doing though

.

Then . . another disaster

.

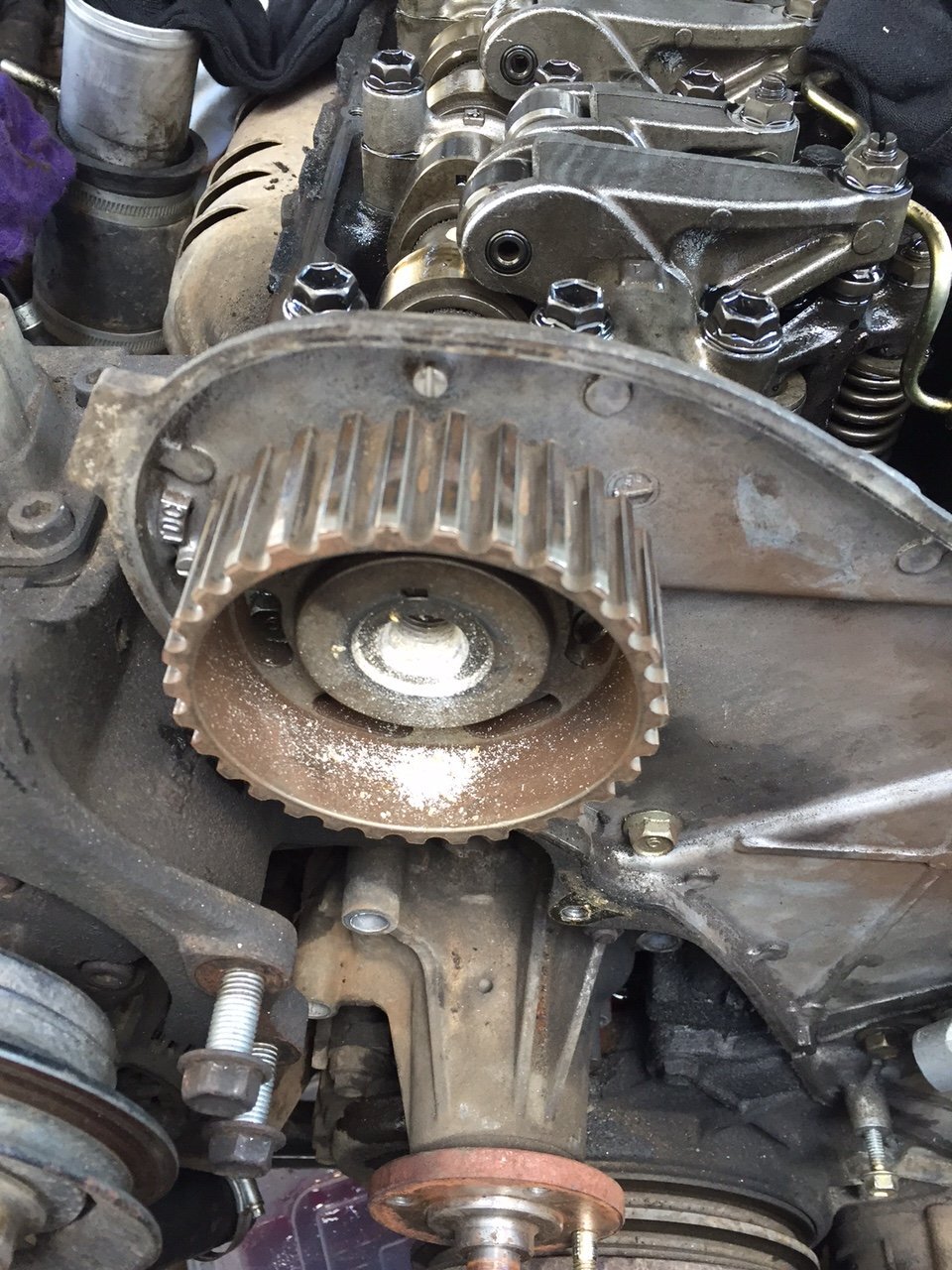

My front suspension rams were leaking so I bought new (genuine Toyota) ones from Roughtrax.

The first job is to set the ride height to 'Normal' then turn everything off.

Then bleed the front Actuators to drop the front suspension. I had been wire brushing and oiling the bleed nipples for some time in anticipation and had bought a set of new nipples and caps to replace the rusty remains of the originals.

Amazingly both opened and the suspension dropped as planned. So I put the new nipples in . . and the O/S one stripped its thread

.

I don't fancy replacing the unit as they are around £600 each so I've ordered a 7mm x 1mm helicoil kit which will hopefully arrive on Monday. The next problem is to find a way of drilling into the side of the unit with only 5 inches of clearance between the chassis and body (I may have sorted that with an air ratchet, a 10mm socket and the small chuck from a flexi-drive. Time will tell). I don't want to remove the old unit as the pipe unions are rusted solid and I'm sure the pipes will fail if I try. I have managed to get four of the bolts out with heat, oil and a lot of patience but I think there is one on top that I can't see.

Its very obvious that the AHC system is assembled on the chassis long before the body goes on as access is a nightmare.

Meanwhile I have replaced both front rams. Getting the top nuts off the old ones was a challenge as there is no access and the nuts were just conical mounds of rust anyway. I had to split them from above with a variety of very sharp cold chisels and a 2.5 lb hammer - that job took about three hours each side.

Now another problem that is galloping towards me - the hydraulic pipe fits to the top of the ram and is sealed with a small rubber ring. The pipe fitting is then bolted down to the ram mounting.

The Ram kit contains the two large rubber mounting bushes and a new top nut, but why don't they include the rubber 'O' ring for the hydraulic pipe ????

I don't have anything that will fit in my 'O-ring kit' so have put the unions back with a smear of red rubber grease. I'm expecting a flood of AHC Fluid when I start the thing up eventually.

No pictures yet I'm afraid (just too hacked off). There is a lot to be said for simple cars.

Bob.

.

.