- Joined

- Feb 2, 2013

- Messages

- 17,191

I used to grip them in the vice after getting enough showing to grip.

I don't remember drifting them all the way out, but it was a long time ago.

Not a chance Clive i can only imagine the bearing pins have melted to weld everything together . I went out to cut it but the mrs arrived home with a broken exhaust so i ended up messing with that . Got a phonecall informing me that my trailer canvas will NOT be done ready for Romania and even my 20 odd year old Zippo lighter packed up sp not a good day really

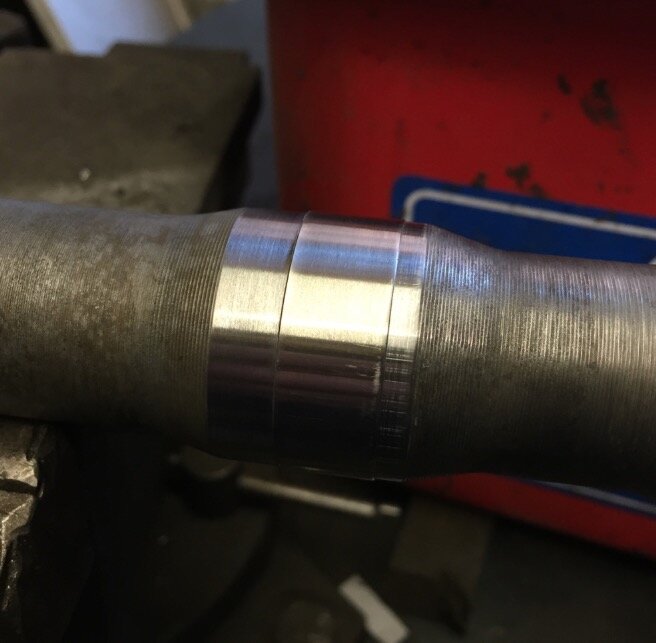

I cut the UJ out and the new one popped in no bother at all - but while pissing about making sure i could get to the new grease nipple i completely forgot about the alignment marks

I cut the UJ out and the new one popped in no bother at all - but while pissing about making sure i could get to the new grease nipple i completely forgot about the alignment marks  I really am pushed for time here i need to get a ferry a 4 and half drive away at 2am tonight for a funeral tomorrow so what do you reckon folks shall i take a chance and put it in as is or .........

I really am pushed for time here i need to get a ferry a 4 and half drive away at 2am tonight for a funeral tomorrow so what do you reckon folks shall i take a chance and put it in as is or ......... Rocker cover .

Rocker cover .