Ok, here's what I've been doing today.

I've now mocked up the whole door in hardboard and timber.

Please excuse the crudeness of this as I haven't had a chance to paint it or complete the CGI interpretation or 3 D CAD drawings ([emoji6]).

First thing to say is that I knew the hinge mechs were wrong but I bought them a while back and I wanted to see just how wrong they are. Reasoning bring that they were readily available BMW parts and took care of the gas strut as well. I now know that I need to go with my plan 'B' for the hinges, which is external ones mounted at the top above the door seal line.

Other things to ignore are the braces across the back of the door, and the extension to the door template (I started with too small a piece of hardboard at the time [emoji36]). The door will just be a piece of ally with a curve to match the LC body, possibly braced with an internal frame of ally angle.

The obvious downside to these BMW boot hinges are that they cut down the available opening, and would dump any and all water into the compartment if opened in the rain. Not good. Plan B sorts this as the door tilts inwards by a few mm at the top on externally mounted concealed hinges, depositing the water around the top of the seal.

Photos so far.

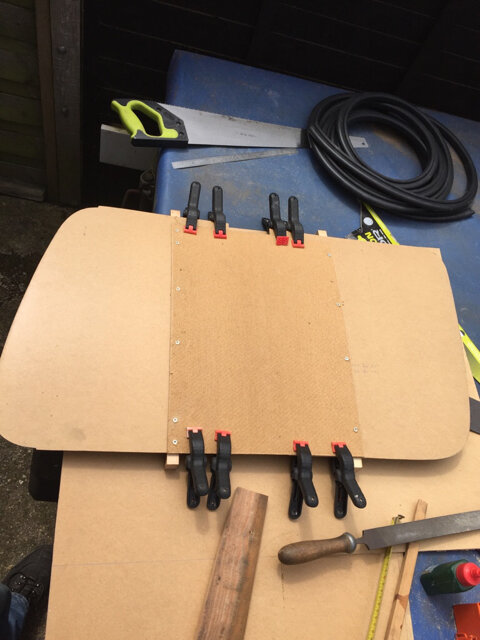

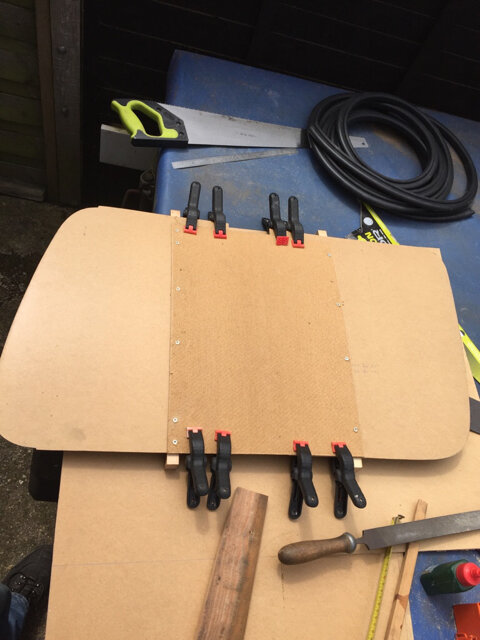

Extending the door template to be the correct length.

Door extended and braced with the curve of the bodywork.

Cut out done, installing the seal.

Seal fitted, spare left for refitting to finished article.

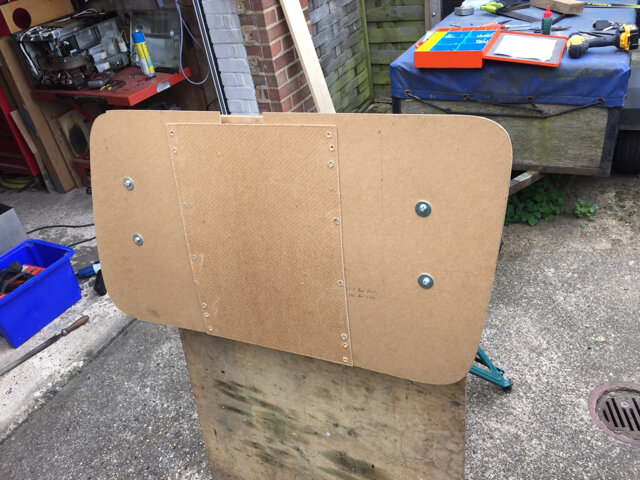

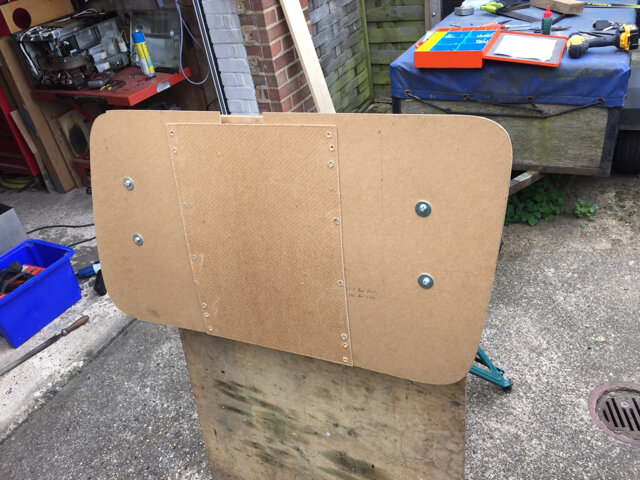

Assembled and mocked up on a supporting board. Ignore the 4 bolts through the door, they are just for mock up.

Side view, showing from right to left, door, seal (black) frame that matches the glass, rear attachment frame for the attachment of the compartment (again mocked up with a bit of timber, would be 4mm (or so) ally all round.

Door open showing just how much the hinge mechs drop the door.

Underneath view, with hinge mechs.

And again.

As can be seen, the hinges are too restricting, they also foul the door into the frame on one side so they're for going back on EBay.

Not a complete waste of time though as mocking it up this way allows me to try different parts out. For instance, I cut the hatch hole too large for the seal to sit right, but with 4mm ally on edge instead of the 1/2" timber on the back, this should not be a problem.

Hopefully this gives an idea of the sort of thing I'm aiming for. It's fair to say I've not given myself an easy ride here, but then I never do!!