Rob

Well-Known Member

Once you can get a pry bar tip, on that corner Chris is talking about, past the bend in the sump sheet metal then it all just comes off really easy. Don't hold back with the hammer and you favorite prying screwdriver to make room for the pry bar. Helps to have a hide hammer when bending it back into shape.

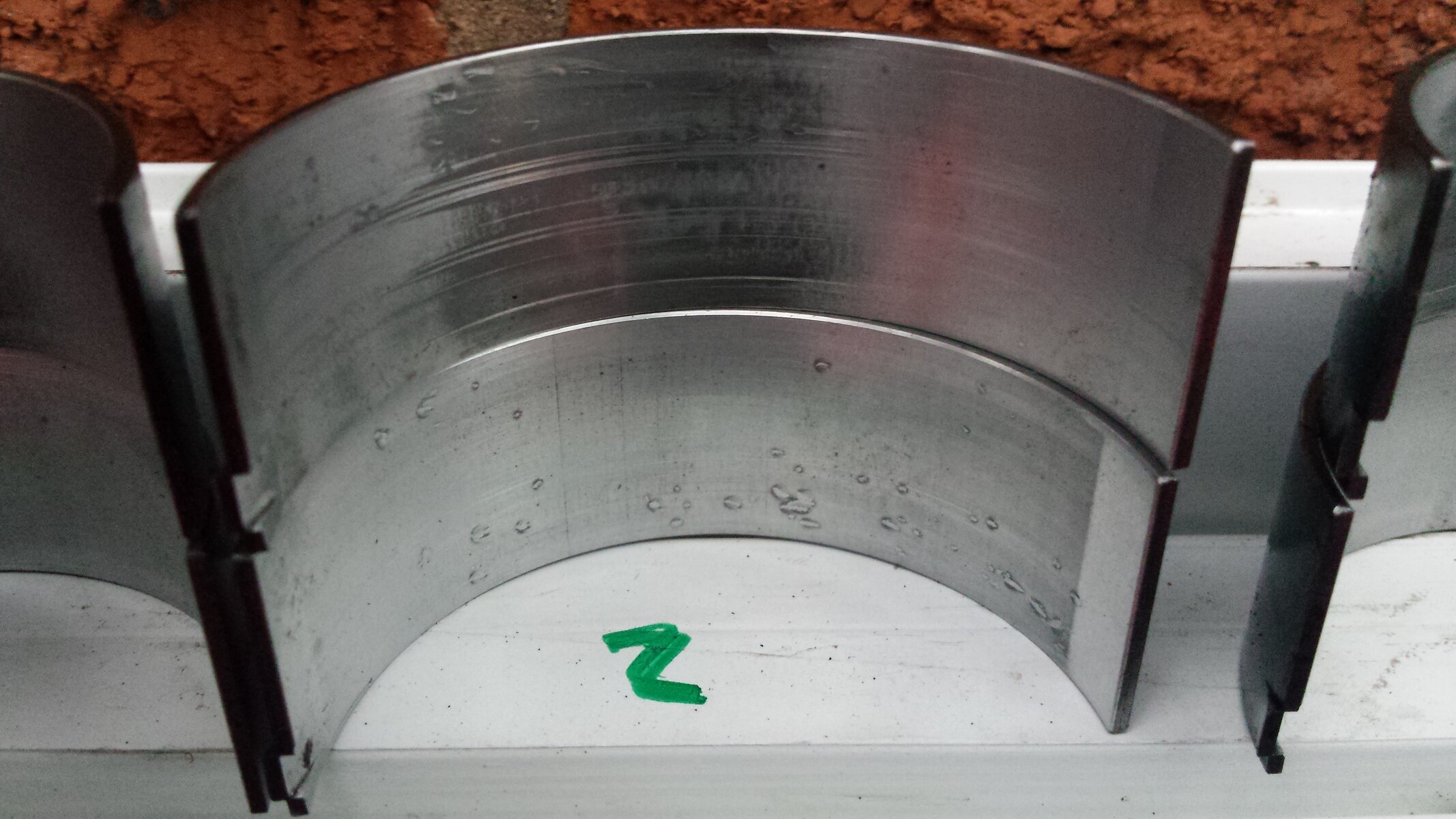

it only takes about an hour to change the bearings themselves.

it only takes about an hour to change the bearings themselves.