AndyCook

Well-Known Member

The factory my neighbour works at purchased a new lathe - the planned to scrap the old one, so he asked if i want it.

its at least from 1970 - a Colchester 5-1/2" (140mm) Bantam Lathe

weighs 343kg

picked it up today, forklift put it in trailer and used my hoist to remove it, will get another neighbour with his tractor to lift it into garage tomorrow.

Not sure what i will use it for yet!, but it seemed silly not to take it since it was free

and need to see what tooling i need to get for it

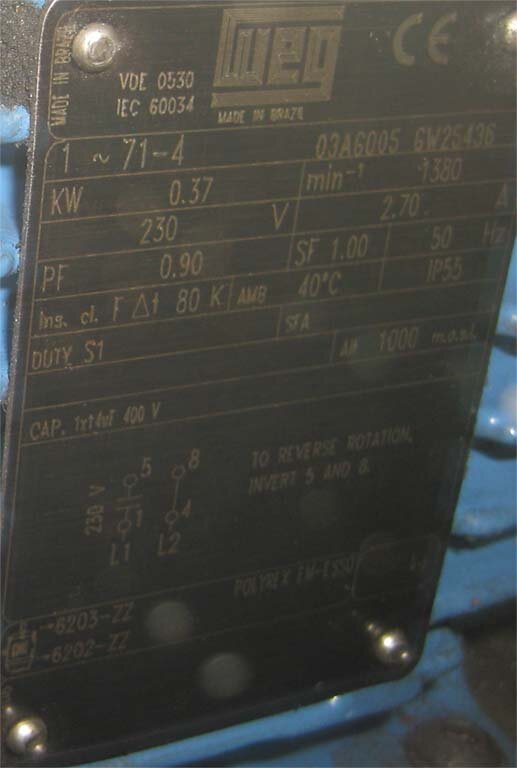

[attachment=4:2r2wpoeg]photo (Medium).JPG[/attachment:2r2wpoeg]

[attachment=3:2r2wpoeg]IMG-20120302-00259 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=2:2r2wpoeg]IMG-20120302-00260 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=1:2r2wpoeg]IMG-20120302-00261 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=0:2r2wpoeg]IMG-20120302-00262 (Medium).jpg[/attachment:2r2wpoeg]

its at least from 1970 - a Colchester 5-1/2" (140mm) Bantam Lathe

weighs 343kg

picked it up today, forklift put it in trailer and used my hoist to remove it, will get another neighbour with his tractor to lift it into garage tomorrow.

Not sure what i will use it for yet!, but it seemed silly not to take it since it was free

and need to see what tooling i need to get for it

[attachment=4:2r2wpoeg]photo (Medium).JPG[/attachment:2r2wpoeg]

[attachment=3:2r2wpoeg]IMG-20120302-00259 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=2:2r2wpoeg]IMG-20120302-00260 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=1:2r2wpoeg]IMG-20120302-00261 (Medium).jpg[/attachment:2r2wpoeg]

[attachment=0:2r2wpoeg]IMG-20120302-00262 (Medium).jpg[/attachment:2r2wpoeg]