Don't like the adverts? Click here to remove them

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Handbrake Solutions

- Thread starter Chris Green90

- Start date

Chris Green90

Well-Known Member

Just to mention I fitted an X-Eng handbrake to my competition LR90 and found it brilliant - never slipped, rarely needed adjusting even after serious offroad action. Had that on the vehicle for 6 years, I think. I know many other guys with them - the only people that thought they were crap hadn't fitted them properly in the first place. Would fit one to my 80 Series LC in a heartbeat, if they make one...

Last edited:

I had a good chat with Simon from X Eng on Sunday. The 70 brake needed a little 'fitting' and some people had expected it to bolt on with Toyota like precision. When it didn't work, they threw teddy out of the pram and posted on some forums as to how crap it was. This resulted in a significant quantity coming back, un fitted, so he told me.

Incidentally, Ben if you reading, I'm not suggesting that you are in this bunch. I know how handy you are and how hard you tried. Not sure that ever found out quite why it didn't work on yours. He had started development on a 80 series but has scrapped that and will NOT be picking it up again. Shame, I'd have bought one too.

So we need to make our own. I like the spot handbrake thingy, but a bit concerned that the stroke on the lever looks like a lot. Maybe better to turn with an electric motor than an air ram. A diff lock motor would be ideal. As it has springs in it, it would be self adjusting with pad wear! Anyway, I need to mock up a back plate first and then see what scope we have. Fortunately, I have a spare T box in the garden so I could do all of this in the garage. Whoopee. Almost warm

C

Incidentally, Ben if you reading, I'm not suggesting that you are in this bunch. I know how handy you are and how hard you tried. Not sure that ever found out quite why it didn't work on yours. He had started development on a 80 series but has scrapped that and will NOT be picking it up again. Shame, I'd have bought one too.

So we need to make our own. I like the spot handbrake thingy, but a bit concerned that the stroke on the lever looks like a lot. Maybe better to turn with an electric motor than an air ram. A diff lock motor would be ideal. As it has springs in it, it would be self adjusting with pad wear! Anyway, I need to mock up a back plate first and then see what scope we have. Fortunately, I have a spare T box in the garden so I could do all of this in the garage. Whoopee. Almost warm

C

Roger Fairclough

Well-Known Member

- Joined

- Dec 14, 2010

- Messages

- 1,106

I ordered an X-Brake for my KZJ70. It did not physically fit. I became involved in the problems that Ben had with his. He was able to fit his X-Brake because he had a 2" body lift and a repositioned exhaust. The problem Ben had concerned the mounting bracket. This is fitted onto cast but not machined afterwards sections of the output flange. This appeared to create an situation where the disc was not in line with the caliper. This created a rubbing action that caused the disc/pad to overheat and this melted the nylon backing pad and that gummed up the works. Ben spoke to Simon and he sent Ben a repair kit. I stripped the caliper, repaired it and re-fitted it. The problem still existed as the flanges still created the original problem. The Land-Rover version fits to the same mounting holes that were originally used to mount the standard drum brake and hence the out of alignment situation does not exist.

Roger

Roger

Ahh, yes. I recall all of that saga now Roger. Not being in line with the disc has to be a major cause of it not working. This is something that I have to get right. The caliper really need to be fully floating.

Chris

Chris

Don't like the adverts? Click here to remove them

- Joined

- Feb 2, 2013

- Messages

- 17,173

http://www.bcsupertrucks.com/store/product/disc-parking-brake-kit/ . Is this not exactly the same thing as an x-eng brake but designed for the 4runner ? Doesn't the lc90 series take most of its parts from the 4runner ? It says this x-brake just bolts on to the transfer case . Isn't it possible the transfer case is the same in both trucks and so the brake should just bolt on ?

Shayne, I don't quite think you are getting the idea. $338 and it's in the USA?

We're trying to come up with a cheap, homespun idea here. There is a certain challenge in it. That is also very bulky and vulnerable. Plus it would be full of mud in a heartbeat.

Chris

We're trying to come up with a cheap, homespun idea here. There is a certain challenge in it. That is also very bulky and vulnerable. Plus it would be full of mud in a heartbeat.

Chris

Why not use the X-eng calliper and disc, and a custom mount? Feels like £200-250 all in should cover it... or did I miss something? I understand the point re the 70 version fitment, but unless the output shaft has an unnatural degree of movement I can't understand why the original design can't be made to work. May just be me being dim

Roger Fairclough

Well-Known Member

- Joined

- Dec 14, 2010

- Messages

- 1,106

The 70 series X-Brake uses a disc that is mounted between the output flange and the propshaft flange. On the Toyota, this connection is made by high strength flanged studs and nuts. Think wheel studs. The X-Brake uses low grade plain nuts and bolts. Because the disc fits between the two flanges, ridged end of the prop can no longer fit into the recess in the output flange. This two parts centralised the prop to the flange and without them, the balance of the propshaft is lost. The disc should have been fitted on the inside of the output flange with suitable high strength fittings. This would have reduced the distance between the disc and the caliper support bracket. This would have strengthened the system. Also, instead of fitting the caliper on the top, where it fouls the bodywork and the exhaust, it should have been mounted on the n/side. In this position, it would have worked. Some fettling of the caliper mounting tubes to ensure that the caliper was inline with the disc may have been needed.

Roger

Roger

- Joined

- Feb 2, 2013

- Messages

- 17,173

I see so its gotta be made up of donor parts and D.I.Y brackets then . I guess there is no point in theory i'd just beg borrow and steal every brake part i could find and set a day aside to experiment trying to fit them all . I wouldn't expect to succeed but by the end of the day i should have a very clear idea of how it can be done and what i need to do it .

Valid point Roger. This is why I have machined my brake disc with that central hole to mate with the prop. I have yet to lie underneath mine when I can to look at where I can stick the caliper. The X Eng one is in my view a bit big, maybe even over engineered. Hopefully a smaller caliper will allow some better mounting options. With using a small air actuator, I also don't need to have to worry about where I run a brake cable. It maybe that having this rather limited where X Eng could mount their brackets.

- Joined

- Feb 2, 2013

- Messages

- 17,173

But while i was writing i had another (probably stupid) idea . If the handbrake gives up because of suspension flex then it seems obvious the cable is being over stressed which is why it pulls out and needs reset . You can't make the cable longer because then it wont work at all ..... unless , you alter the handbrake lever so the cable connects to it further forwards . This means when you pull the handbrake up your pulling more cable in to activate the brakes , but when you put it down your adding a few inches of slack which might be enough to let the suspension flex without harming the brakes .

Chris Green90

Well-Known Member

I know we have 2 seperate threads running here but hopefully I may have a plan to bring them both into on. Chris you maybe over engineering this a shade. (Not that that's not your usual style.)

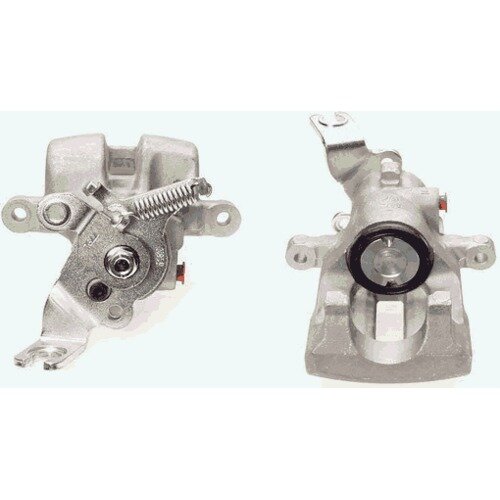

Euro Carparts (Not overly sure how reliable they are) list the rear caliper for the LC90 1997, 4.2 LC80 1996, and Toyota Avensis 2001 as the same part number. Now the one from an Avensis I put a pic up of earlier is from the T22 model (Faster, harder etc. I am guessing.) But is it likely that Mr T changed the mounting brackets for this particular vehicle. Surely it is more likely that they built the caliper to fit the existing mounting points and there fore logic would follow that the T22 caliper should be a straight swap. All that is then needed is either the cable setup from a Rav4 or even Avensis if it is double pull. This options as far as I can see should work for both the 80 and the 90 (may also be the same for the 70 but I haven't Checked.

It may not be the cheepest option if you had to buy the parts new (c.£325) but if you could get them from a breakers etc I recon you could be looking at less than 100 quid and a damn sight simpler too.

Euro Carparts (Not overly sure how reliable they are) list the rear caliper for the LC90 1997, 4.2 LC80 1996, and Toyota Avensis 2001 as the same part number. Now the one from an Avensis I put a pic up of earlier is from the T22 model (Faster, harder etc. I am guessing.) But is it likely that Mr T changed the mounting brackets for this particular vehicle. Surely it is more likely that they built the caliper to fit the existing mounting points and there fore logic would follow that the T22 caliper should be a straight swap. All that is then needed is either the cable setup from a Rav4 or even Avensis if it is double pull. This options as far as I can see should work for both the 80 and the 90 (may also be the same for the 70 but I haven't Checked.

It may not be the cheepest option if you had to buy the parts new (c.£325) but if you could get them from a breakers etc I recon you could be looking at less than 100 quid and a damn sight simpler too.

Last edited:

Chris Green90

Well-Known Member

But while i was writing i had another (probably stupid) idea . If the handbrake gives up because of suspension flex then it seems obvious the cable is being over stressed which is why it pulls out and needs reset . You can't make the cable longer because then it wont work at all ..... unless , you alter the handbrake lever so the cable connects to it further forwards . This means when you pull the handbrake up your pulling more cable in to activate the brakes , but when you put it down your adding a few inches of slack which might be enough to let the suspension flex without harming the brakes .

That seems quite logical.

I'm not over engineering anything there my old Northern buddy. I am simply putting a disc on the prop and a small caliper. It's not me making the barmpot suggestions.

I am doing it this way because that's what I bloody well want to do!

C

I am doing it this way because that's what I bloody well want to do!

C

Chris Green90

Well-Known Member

Sorry Chris thats not quite what I was implying. TBH it was me that put forward the idea again so I must shoulder some of the responsibility. I still think that what you are doing is great and had no intention of implying that it was a barmpot idea. It is why I suggested the thread be split. I must admit that without you fabrication skills or tools I am looking for as much of a "bolt on" Solution as possible and if it passes an MOT then Great.

I like the idea you are proposing and having its operation via a lever and cable as opposed to air ram or cable and motor is a simple enough step. I never intended this thread to but a quick solution to a proble we have had for years but more somewhere to bounce ideas around to come up with (as you said) something cheep, reliable and most importantly that solves the probelm. I feel that even some of the more out there suggestions have aided in the search for a solution and I hope this thread continues in the same vein (Unless you think my idea is one of those barmpot ones then I'll shut up right now and just wait for you to make me one ) but seriously If you think the way I am running is way way out there then please let me know. I wouldn't want to run off in totally the wrong direction.

) but seriously If you think the way I am running is way way out there then please let me know. I wouldn't want to run off in totally the wrong direction.

At the end of the day what you are proposing chris is a proven technology (basically) AFAICS the only reason for the X-Eng one not working properly is the mounting positions and frome what has been said today a little more thought would have overcome those easily.

I like the idea you are proposing and having its operation via a lever and cable as opposed to air ram or cable and motor is a simple enough step. I never intended this thread to but a quick solution to a proble we have had for years but more somewhere to bounce ideas around to come up with (as you said) something cheep, reliable and most importantly that solves the probelm. I feel that even some of the more out there suggestions have aided in the search for a solution and I hope this thread continues in the same vein (Unless you think my idea is one of those barmpot ones then I'll shut up right now and just wait for you to make me one

At the end of the day what you are proposing chris is a proven technology (basically) AFAICS the only reason for the X-Eng one not working properly is the mounting positions and frome what has been said today a little more thought would have overcome those easily.

Chris Green90

Well-Known Member

That seems quite logical.

Then again would there then be enough travel in the lever to take up the slack. Now I think about it definately not. You would not be changing the distance the cable is pulled only where it is pulled from.

- Joined

- Feb 2, 2013

- Messages

- 17,173

I think i'm the said barmpot but i do occasionally say something logical by accident

http://wilwood.com/Calipers/CaliperProd.aspx?itemno=120-8835

http://wilwood.com/Calipers/CaliperProd.aspx?itemno=120-8835

Similar threads

- Replies

- 11

- Views

- 485

- Replies

- 10

- Views

- 286