Thanks all! My hair was thinning before the work, I definitely think I've a solar panel on my head now!

Everything, so far, is fine. It's driving well, no black smoke at all now and I dare say the MPG's are getting better too (although there's more to that which I'll go in to in a separate thread).

Anyway, as promised, the part numbers to do the job as of 2022 - including the bits I broke and lost.

| Part Number | Description | Cost (from Mr.T - exc VAT) | Quantity |

|---|

| 23681-30010 | Seal, Nozzle | £2.70 each | 4 |

| 23701-30030 | Injector Pipe | £130.85 | 1 |

| 23702-30030 | Injector Pipe | £130.85 | 1 |

| 23703-30030 | Injector Pipe | £130.85 | 1 |

| 23704-30030 | Injector Pipe | £130.85 | 1 |

| 90904-30013 | Gasket | £9.68 | 5 |

| 11213-30021 | Gasket, Cylinder | £13.21 | 1 |

| 11176-30011 | Seat, Injector | £3.41 | 4 |

| 96721-19017 | Seal | £3.75 | 4 |

| 90209-10021 | Washer | £1.36 | 4 |

| 23743-30011 | Clamp, Injector Pipe | £6.18 | 1 |

| 23679-30021 | Screw | £5.53 | 4 |

| 90105-08374 | Bolt | £2.61 | 4 |

The "Clamp, Injector Pipe" isn't required if yours are in a good condition. Mine wasn't, as one side had been put on wrong so the rubber had deteriorated. This is only for one part of the clamp too, so I imagine if you want the full clamp you'd order two of these.

The "Screw" (part no. 23679-30021) is an upgrade part, holding the return fuel rail to the injectors. The old one is a 17mm head, this new part has a 12mm head. This, apparently, is so it doesn't foul the gaskets - which I can well believe being the case. The bolts (part no. 90105-08374) are a must, because - well you know why!

Injectors were purchased through Specialist Diesels, and they list the part number of

23670-30080. Best way to find them though would be to use Google, as when I called up they said they didn't do injectors for my Land Cruiser. But when I Googled the part number given to me by Toyota, their own website listed the specific injector. I think this is because they rely on the old part numbers, but when they have new part numbers it's put under an alias kind of thing and probably not visible to them over the phone. Those injectors cost £705.00. They also come with the old copper washers for some reason, so don't rely on the refurbed injectors to come with the washers you require. Buy these from Mr.T.

I'm currently dying at the moment with a non-COVID head cold/flu, so I feel amazing. I'll get the video together next month and put it here as a guide to whoever needs it.

A Word About TechStream/Injector Programming

I will say that you should get the injector compensation codes from the injectors before they go on to the car. I didn't do that, I started taking photos of them when I put them in, which isn't ideal. D's look an awful lot like 0's, and 0's look like 6's if there's a scratch or a bit of dirt on the plug. From what I found mistaking D's for 0's is that Techstream won't allow you to enter incorrect codes. I don't know how it knows, the hexadecimal code must follow a specific pattern so it won't allow you to type in the wrong digits. I wouldn't fully trust this though, so triple check your codes before you enter them on Techstream.

For those who don't know, the codes follow a hexadecimal format. The digits will range from 0 to F. So while there are letters on there, if you see a 1 it will be a 1, it won't be an I or and L.

Techstream, without a doubt, was the biggest pain in the arse to get right through the whole process. For me it was worse than the panic of breaking the stretch bolt. You can't fully rely on the eBay bought ones. I will also say though that, I think, any issues relating to viruses is down to how the software behaves on the computer. I don't think there is any malicious code being run on my copy, but that requires further testing when I have 10 minutes. That said, you would be better to run this on a PC/Laptop that doesn't talk or isn't connected to the internet in any way.

Other Tools

To add to the tools listed previously, I really do think this job should be tackled with:

- Carb cleaner (and lots of it)

- Compressed air/can of compressed air

- A decent quality torque wrench (upwards of £90)

- 14mm dowel (if you can't find 15mm, which I couldn't)

- An old shirt

- Blue/white roll - and lots of it

The torque wrench I used first (Silverline, £20?) thing I feel contributed to the breaking of that bolt, as well as a drop of oil running down the thread. For this reason you are best to soak the thread wells with carb cleaner then blast it with compressed air. It gets messy! But then the difference in feel of tightening the bolts, even with a looming panic attack, was amazing. You feel like you have granular control over the torque of the bolt when tightening, and inspires confidence on a job that can go very wrong very quickly. I ended up buying one from Halfrauds for £90 that comes with a certificate of calibration, as I read it is manufactured by the UK's leading/most respected tool maker. I am looking to upgrade my 1/2" wrench as well with the same one at some point when I need it.

Also wrap the dowel in the old shirt and dowse it in carb/brake cleaner and give it a good on rub. The seats want to be mirror perfect.

Don't Fully Rely On Techstream

I started this by running the injectors through Techstream to see their operating parameters. Cylinder 1 was running at -1.0 while the rest were in and around 0.0. I can tell you, as you have seen, the injector on cylinder 1 was quite bad, with cylinder 4's injector following behind. If I had relied on Techstream on it's own the injectors wouldn't have been changed, and I reckon I'd have had a much dirtier messier job on my hands if I had allowed it to carry on. If you have the rattle on cold, if you're announcing the pope on start up, I think you should take that as the sign to get the injectors changed.

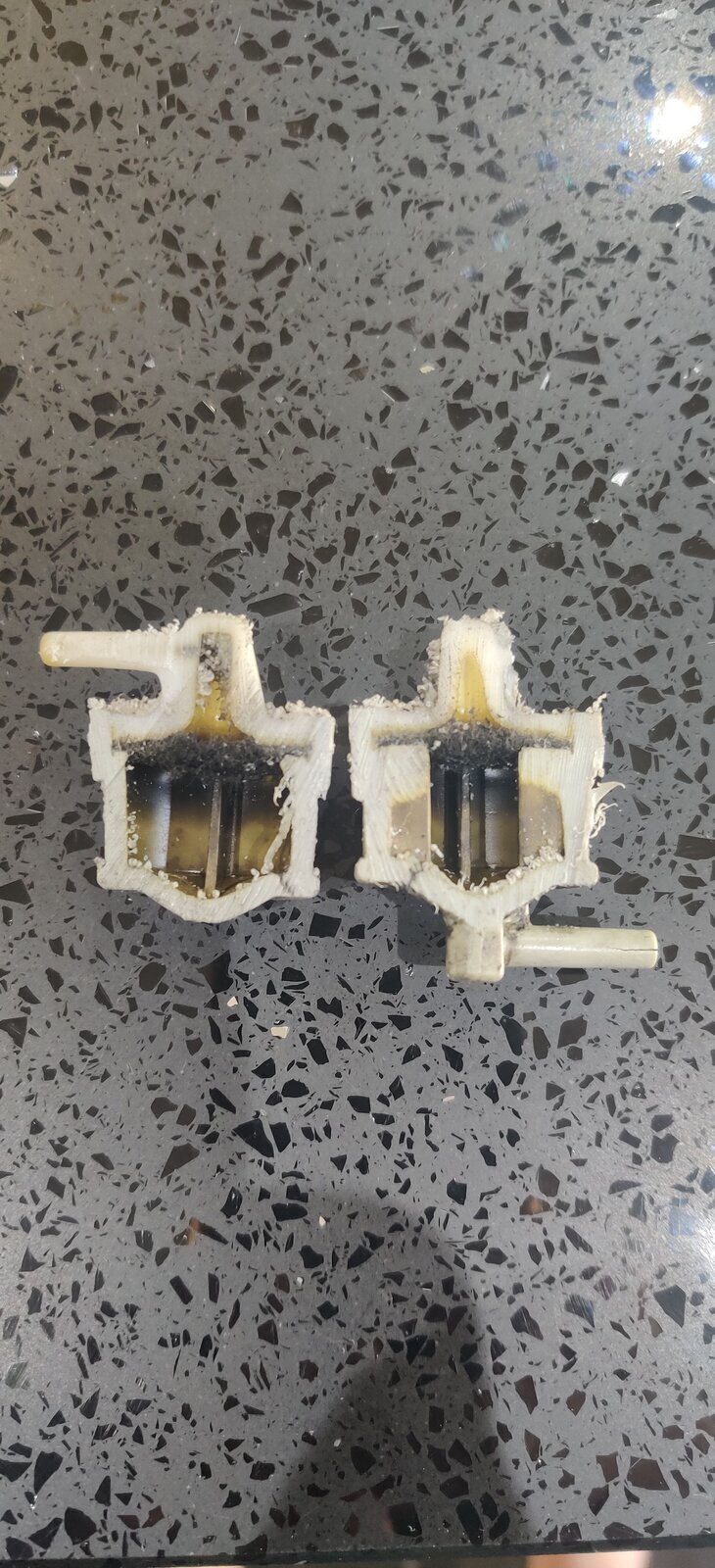

Sludge

I think I'm quite lucky (so far) that the sludge was concentrated on the top of the engine and didn't get down to the sump. The sump had never been off (as far as I could tell) and was incredibly clean, backing up what I saw with the camera. I would budget for more frequent oil changes to make sure you clean the engine (rather than relying on engine flush stuff). I've got 15 litres of Petronas Syntium - as it was cheap at the time and I quite like the stuff - and I plan to do an oil change in about 3,000 - 4,000 miles time. I won't be removing the sump or rocker covers to see the state of it after this as I don't think it's needed, but the next (at least) 3 oil changes I'll be doing at short intervals before going back to 8,000-10,000/12 months.

Time

You could well do this on a Saturday. I was doing other things like cleaning the EGR and adding the Aussie box of magic so I got sidetracked, and Techstream took a good 2/3 hours to get working properly on the laptop. That all eats in to your time, so if you're more organised than I am you'll do all of this the night before and just get cracking on it on a Saturday.

Once again thank you to everyone on this thread for the help and support!