Caprentry Project, Jimny Project, Maruti Project, Work Bench Project and new welder!

LJ has been working hard again carrying timber for another little carpentry project.

This time 5 meter lengths!

As I needed a lot of pieces of wood the same length I set up a stop for the chop saw.

Guess what I'm making yet?

The new bench once again came in very useful!

Raised planter boxes for the deck that I recently fixed up.

Cut some timber to cap the tops off with.

Cut more timber.

Added a shelf for the plant pot to sit on.

They just need staining now.

I cant decide whether I will go back to my roots as a carpenter and set myself up making custom furniture/joinery out of wood, or open a workshop designing and building custom 4wd stuff. Either way I want to work for myself at home in a workshop! But that will be a few years off yet, once I'm done in the mines and living on the East coast.

OK 4WD projects next....................................

I finally got some time to do a bit of work on our Jimny buggy project. This project has had to take a bit of a back seat while we focus on paying jobs, so its going to be more of a long term project.

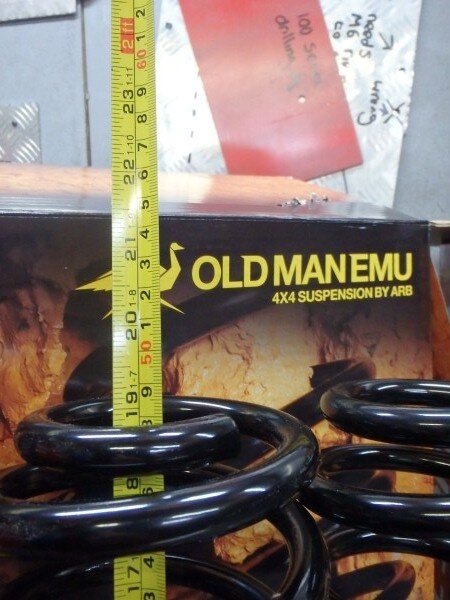

I got some of the longest, off the shelf springs available. Jeep Wrangler front springs.

The idea will be to have the truck sitting reasonably low for stability but with loads of droop and articulation. So although there big springs I'm not building some jacked up monster truck, I will just weld the spring purchases onto the chassis higher up.

Old spring perches.

Plasma cut them off.

The spring perches on the axle were too far inwards and were the wrong size.

Plasma cut them off.

Cut some 6mm plate and welded a piece of tube to it.

Tacked it in place.

And fitted a rubber spring seat to it.

That was all I managed to get done on that as we had a customers Suzuki in for a few days which I had to fit suspension, wheels and tyres, cut the arches and add flares, front winch bumper and rock sliders too. No pics of that one, but once that was done I could get back on with my Maruti project!

I needed to clean the tank out as it was full of black sludge.

I squirted a load of degreaser in it and then steam cleaned it.

I then removed the seats from the Maruti and gave it a good clean.

The tail gate was knackered.

So I found a better one.

Re-fitted the tank.

I removed all the plastic flares and did some guard chopping next.

Did that both sides then gave it a very quick sand down with the air sander.

Ready for paint.

1 litre of white enamel.

The next day after I had re-sprayed it.

Started bolting stuff back in.

Roll cage first.

And bull bar.

Interior bits next. Floor mats, seat belts etc.

The tray looked pretty tired.

Rubber matting.

Much better!

As its off road only we dont need side repeaters, so I cut and painted some checkered plate to blank the holes with.

Added the checkered plate that caps the back off the dash board off.

And flares.

Seats.

It now starts and drives perfectly and I took it next door so the auto electricians can wire up the lights.

Its now very close to being finished and sold! I just need to add some of my tube doors, fit a modified airbox (due to the 4" bodylift) and run the engine up to temp and check for any leaks.

Added some of our stickers in place of the original Sierra badges.

I picked up the work bench I'm building for the auto electricians from the powder coaters.

Bolted the castors on.

When I get time I need to fit a wooden top, shelves and back board to it.

I finally got my TIG welder!

Need to fit a 3 phase plug to the end, then I want a 3 phase female socket on a cable with a 240volt plug on the other end so I can use it at home and work.

The foot pedal.

Torch.

It seems like a good one.

Its super flexible which will be useful when welding roll cages etc.

It will live at work where its covered by the insurance and is in a very secure alarmed building with CCTV cameras every where but I want to protect my investment from anyone messing with it if I'm not there, or anyone just walking out with it. So I'm going to build a secure metal cabinet for it and weld it underneath my bench. Should also help keep the dust out of it as it will be sealed until I want to use it and open the doors.

Got it on the bench to measure it up.

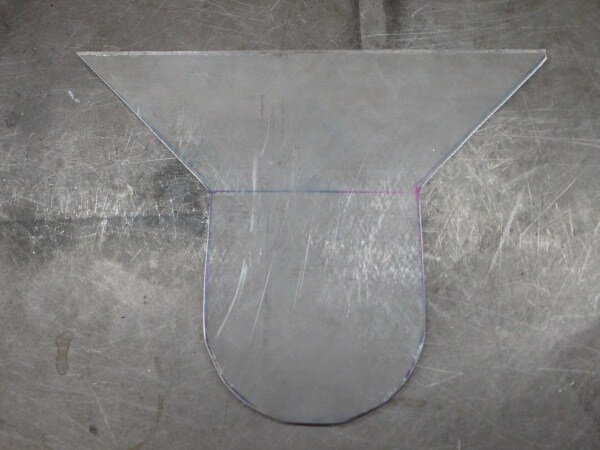

Marked and cut some 3mm steel ready for folding.

And thats as far as I got.

I will get the welder setup next week and now as TAFE has finished until February/March I can practice like hell for my welding test.

Have a great weekend guys!

Going to be lovely and warm here, 26 today and 32 tomorrow!