Long time no update...........................

LJ

I brought back some more carpet for LJ when I was in the UK a few months ago.

This time I managed to find the pieces that cover the rear wheel arches out of a KZJ70.

They finish it off nicely.

So its just the boot carpet I need now and a new jack cover and the interior is complete.

Sadly I havent been able to do work on it for months and have accepted the fact it wont be back on the road this year.

Gates

Gates

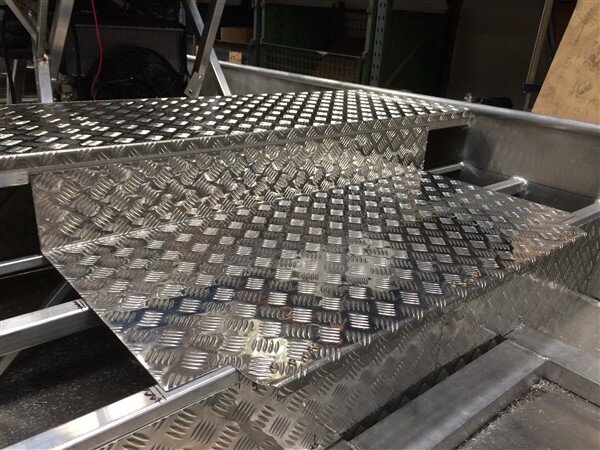

I needed to build a gate to secure the other side of our house on our second driveway.

You may remember I built this set last year before we moved in.

I decided to make this one a bit different as its not as visible from the road and wont be used everyday.

50mm x 25mm steel box section welded together at work, then brought home on the roof of The 78 and painted satin black..

Which I then clad in some corrugated sheets.

Garden Terracing

Garden Terracing

So the reason I havent posted in a long time or even been on the forum is the garden project that turned into a massive job!

My original thought was I will hire a digger and bobcat for a weekend, dig out the top of the garden and move that dirt to behind my retaining wall that I built and also dig out the very bottom of the garden to level that area up, move all that dirt up to behind the retaining wall, compact it down with the bobcat and job done! 1 weekends work!

I hired a digger and a bobcat however there was a little bit of confusion as the hire company asked if they could drop the machines off early and did I have plenty of space.

Well I thought he meant space to store the machines but he actually meant space to work as he didnt have any 1.5 ton bobcats left and wanted to instead upgrade me to a much bigger machine.

This is what got delivered!

It was an absolute monster and isnt even list on their website under Bobcats.

Going back to my original thought of getting it all done in one weekend there was one thing I massively overlooked, in fact I didnt even consider it................

It was the middle of winter and how wet the ground would be.

Suffice to say the bobcat was soon bogged as I got a little bit carried away pulling tree stumps out.

Thankfully my mate turned up to help and dragged the bobcat out with the little digger.

The bobcat was a real beast with a mountain of torque and power! It lifted and moved that old concrete slab that can be seen in the pic above, like it was made of paper! And some of the tree stumps it pulled out were huge!

But an hour later it was stuck again and this time much worse than the first time.

It took us 2 hours to get it out, by using the bucket to lift the front of the machine up and then putting timber underneath it to raise it up.

Eventually we got it out and I then pulled up and broke all the storm water pipe pulling a tree stump out that had grown around it.

We did some digging down the bottom of the garden and I used the bobcat to dump that soil and clay up and over the retaining wall further up the garden.

But that too soon turned into an impassable quagmire and the ground leading up the garden was becoming so slippery and not wanting to risk machines being stuck that far down the garden we had to abandon work in the back garden.

As it was Sunday afternoon by this point and I still had a few hours of light left I decided to widen and straighten the front driveway!

I got some crushed rock delivered and wackered it down. I'd like to concrete the whole thing really or go over it with some nice gravel but I want to give it time to all settle first.

Enough parking for lots of cars now!

I used The 78 to drag a big palm thing out of the middle of the front garden as it was a pain to mow around and didnt really suit our garden as non of our other plants are tropical.

We put it on facebook market place 'free to good home' and a women came and picked it up and as they had just built a house and this was the first plant in it she was going to build the rest of the garden around it.

Back to the mess of the back garden..............

Looking around at the devastation it was a little overwhelming thinking where to start!

This is the mess I ended up with after the machines had had a weekend digging and moving dirt.

But I decided that I would just have to do as much as I could by hand as it would be months before it would dry up enough to get machines back in.

There were some big rocks that the digger couldnt wrench free from the ground so I broke them up and dug them out.

Damaged my favourite pick axe though.

I didnt want to dump dirt here but after I dug out the driveway it had to go somewhere and I couldnt risk getting it any further down the terrace.

I had dug out and saved a lot of rocks.

I needed to dig down a couple of feet at the top of the terrace to make it level with my meter high retaining wall, but I hadnt counted on the storm water and sewage pipes being buried so shallow so they would both need lowering.

I made a start and dug out the section in front of the old garage base and had to dig and break my way through quite a bit of bed rock and clay.

With all the rock coming out of the ground and the piles I already had I had the crazy idea of building a huge retaining wall out of it along the top of the terrace.

For someone who has never built a wall out of anything other than timber and steel before I knew it wouldnt be easy but was confident I could do it.

But first I needed to lower and repair the storm water pipes.

You can see in the pic below the solid bed rock I had to break through using nothing more than a 1.8 meter steel bar and a shovel.

One of the storm water pipes was blocked lower down and as soon as I build the extension these will pretty much become redundant as one of the overlays on our property is to do with rain water run off and the council insisting that all storm water must now go into the storm water drains/pipes under the road, where as when our house was built it was just piped out into the garden and dumped in a soak away, so thats why I was happy to go 2 into 1 with the storm water pipes.

Pipes repaired and lowered.

Next I needed to lower the sewer pipe that can be seen to the right of the storm water one, but first I would have to dig and move a few more square meters of clay and rock.

And as I dug the rock pile grew!

Working conditions were tough as it was a quagmire and the almost constant rain wasnt helping.

So I got a load of pallets to use as duck boards and they worked beautifully!

Lots more bed rock was being broken and prised from the ground.

Sewer pipe lowered and extra roding/inspection points added.

So with all the pipes now lowered and repaired and a load more clay and rock dug out the site was starting to take shape.