Long time no update on this thread……..

So following on from the previous update, I painted the rust repair, refitted the screen and we took The 78 away for an amazing month long trip to Tasmania last Christmas.

Pics from that trip are on the page below:

Do you have to fill in the logbook for mileage with the club reg when you use them? I guess limited miles per year? IIRC the VIC scheme is days per year; the NSW scheme has followed the VIC one, and up here we can use them for x number of days a year + club events. So if you get it right, you...

www.landcruiserclub.net

After that trip The 78 developed a noise which to start with I thought was the gearbox, but it turned out to be the rear diff.

I was really annoyed it had failed because I’d had that diff expertly rebuilt with a new ring and pinion and solid pinion spacer and I hadn’t driven particularly aggressively or on big tyres.

After speaking to my diff guy he thinks the old diff went bang due to the weight the 78 was carrying (especially last Xmas) with all the power going through the little 8” diff.

He said if I wanted it to be absolutely bomb proof then I needed to use a 75 series housing with 100 series 9.5” diff centre.

I’d be loosing my factory locked rear diff sadly, but I’d be upgrading that 8” diff to a 9.5” and gaining fully floating axles (half shafts) at the same time.

Axle removed.

Damaged 8” diff.

I picked up a rolling FZJ75 chassis for $1050 (I went on to make $1300 selling the bits I didn’t need, as all I used was the housing and axles).

I also picked up a 100 series rear axle and I made $200 profit selling all the bits I didn’t need, such as the housing, axles (half shafts) and brake backing plates.

Cleaned up the 75 housing and removed the leaf spring mounts.

Carefully removed all the brackets from my old LJ78 housing ready to weld onto the 75 housing.

Stripped 78 housing.

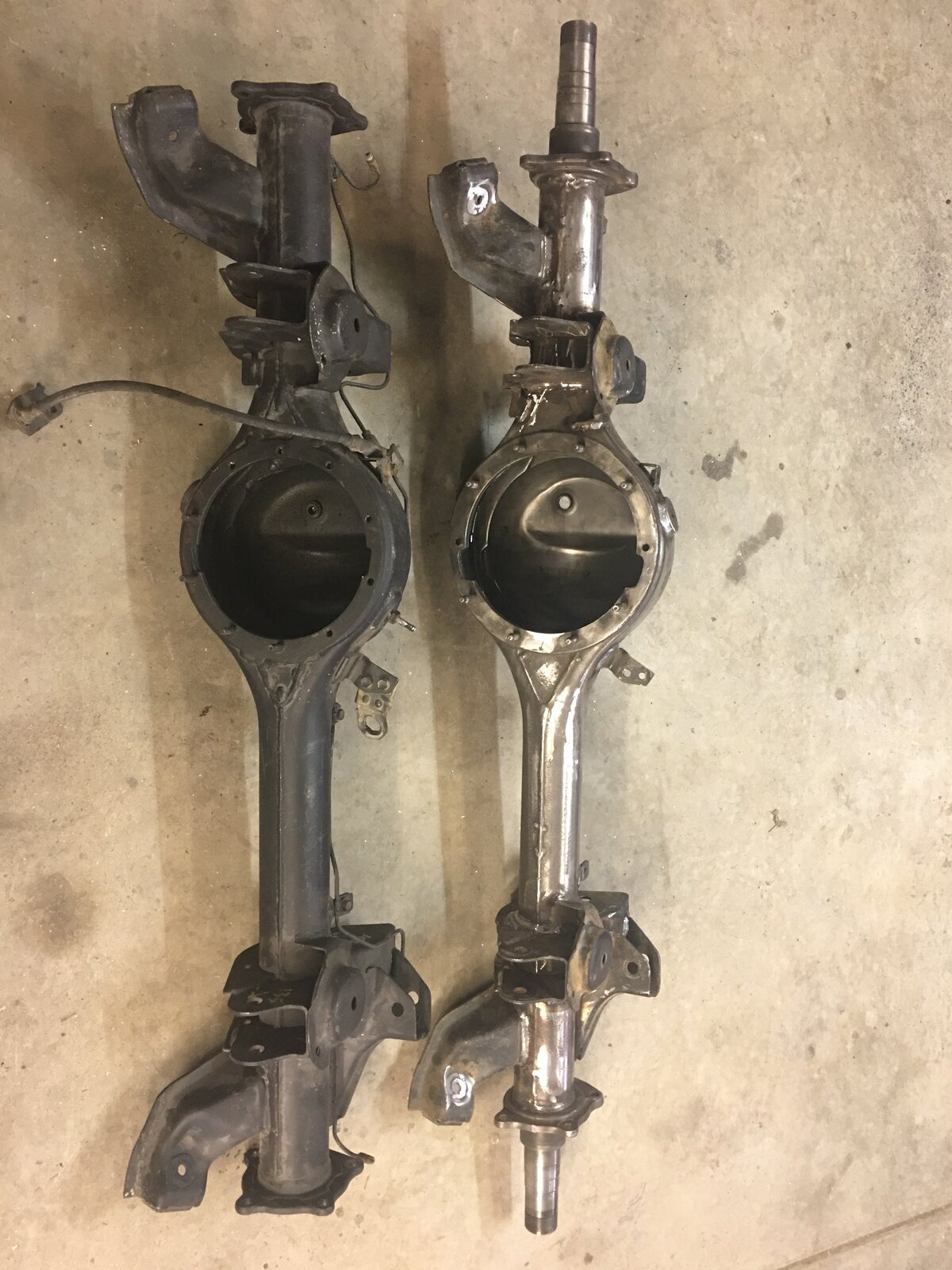

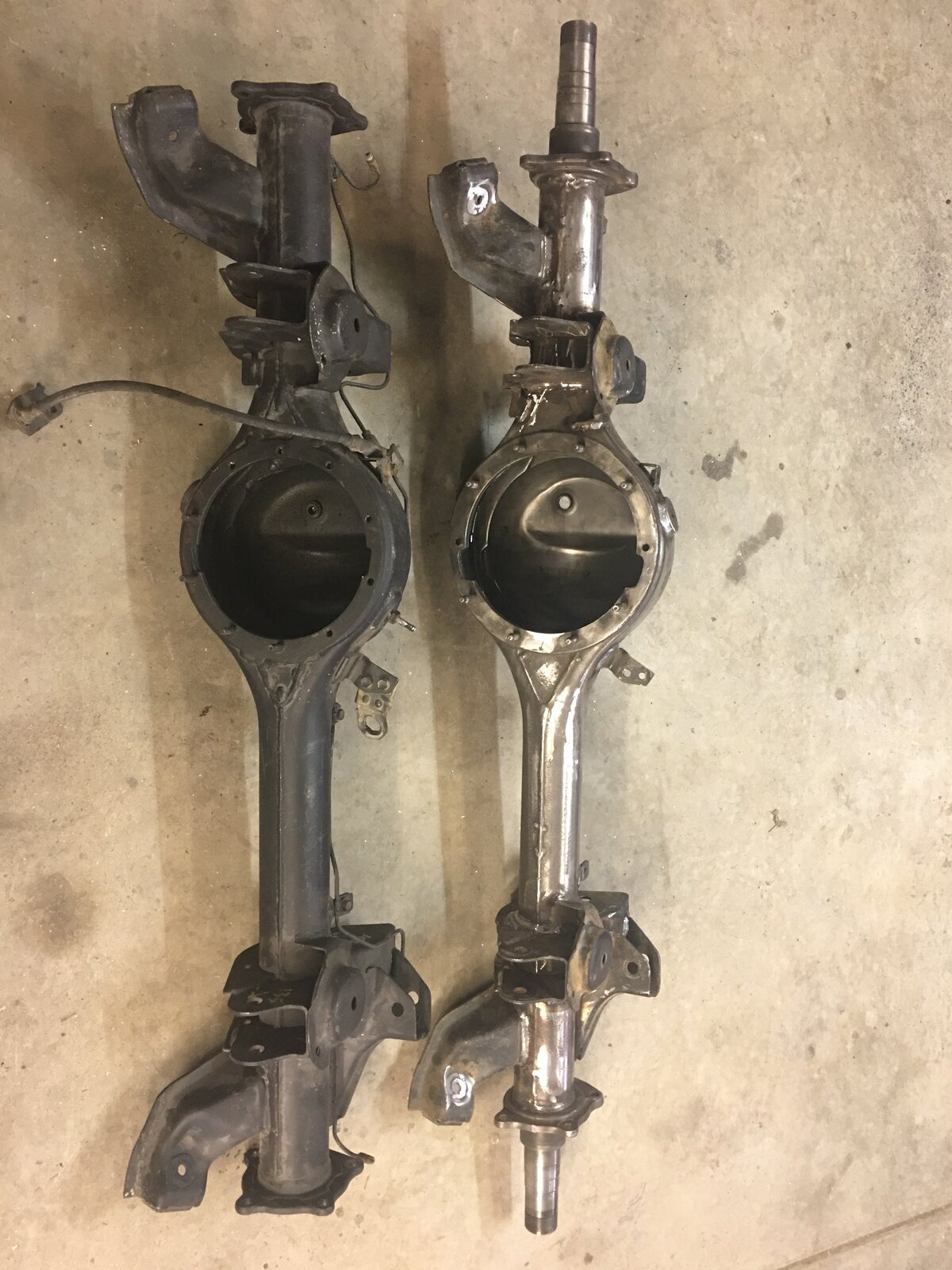

The 2 housings together.

Both the same width, but the 78 is semi floating and the 75 is fully floating, which is a big advantage!

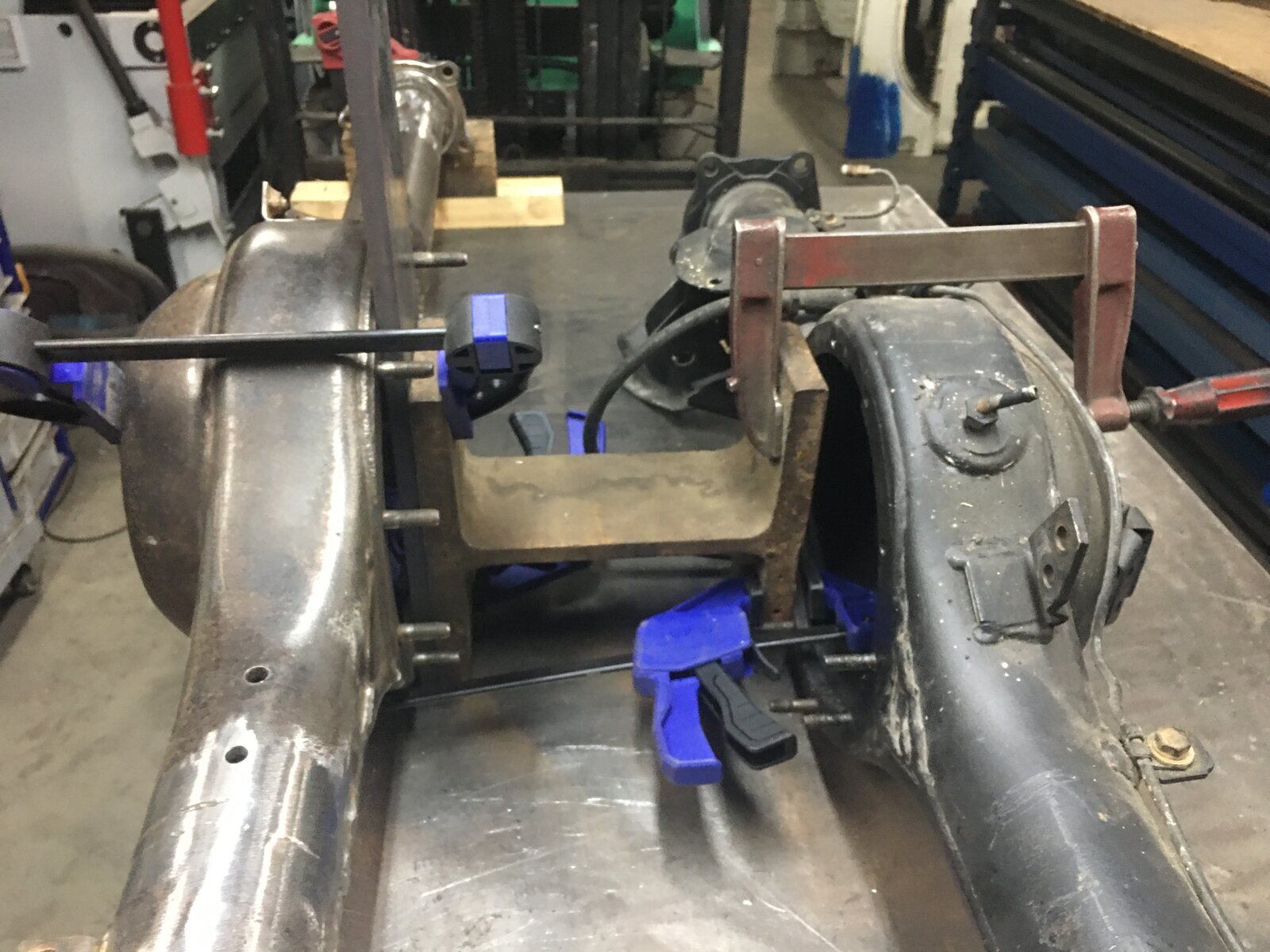

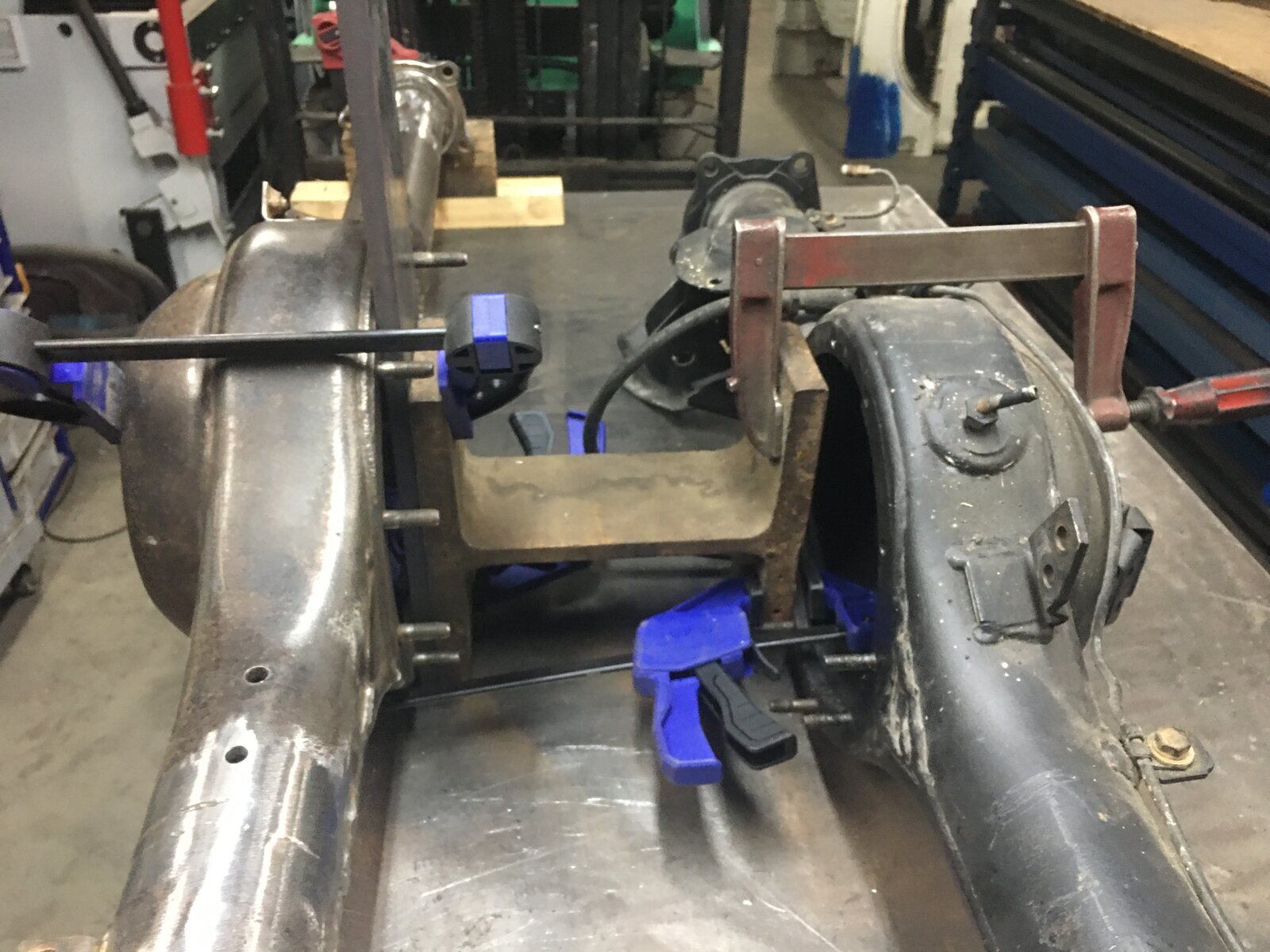

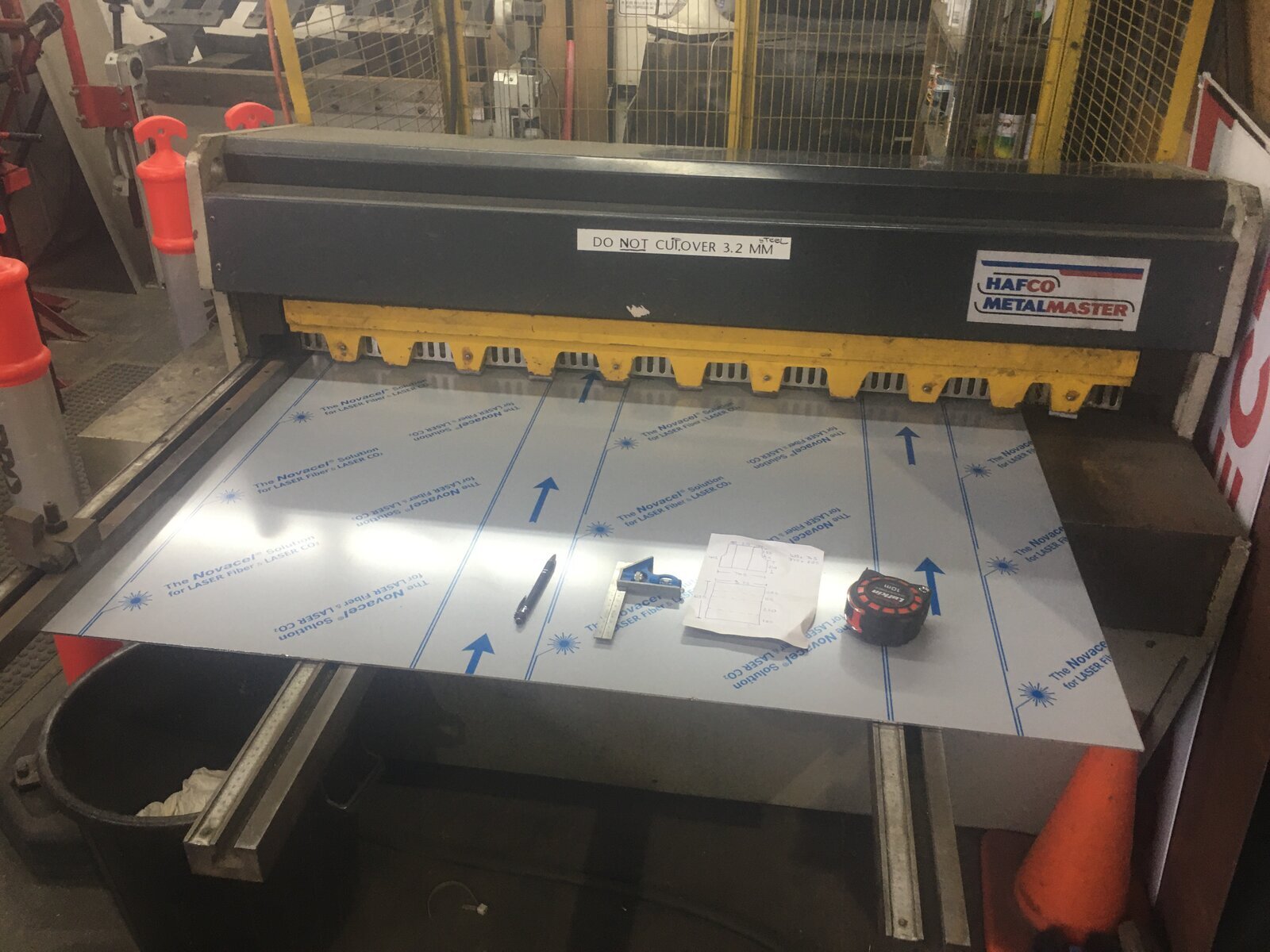

I took the 75 housing to work along with my spare KZJ78 housing, which I used to take measurements and angles from for the brackets.

Brackets all welded on.

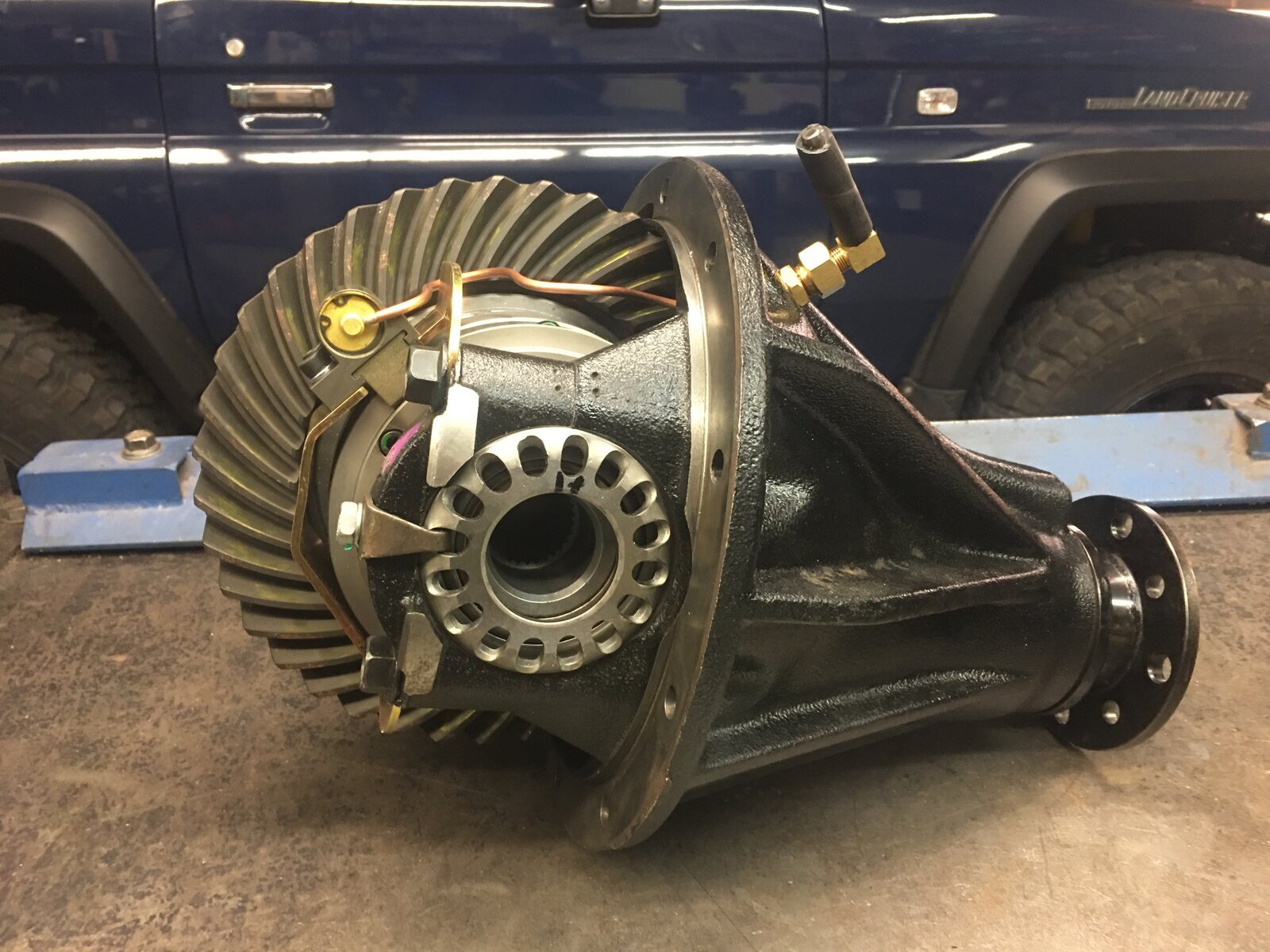

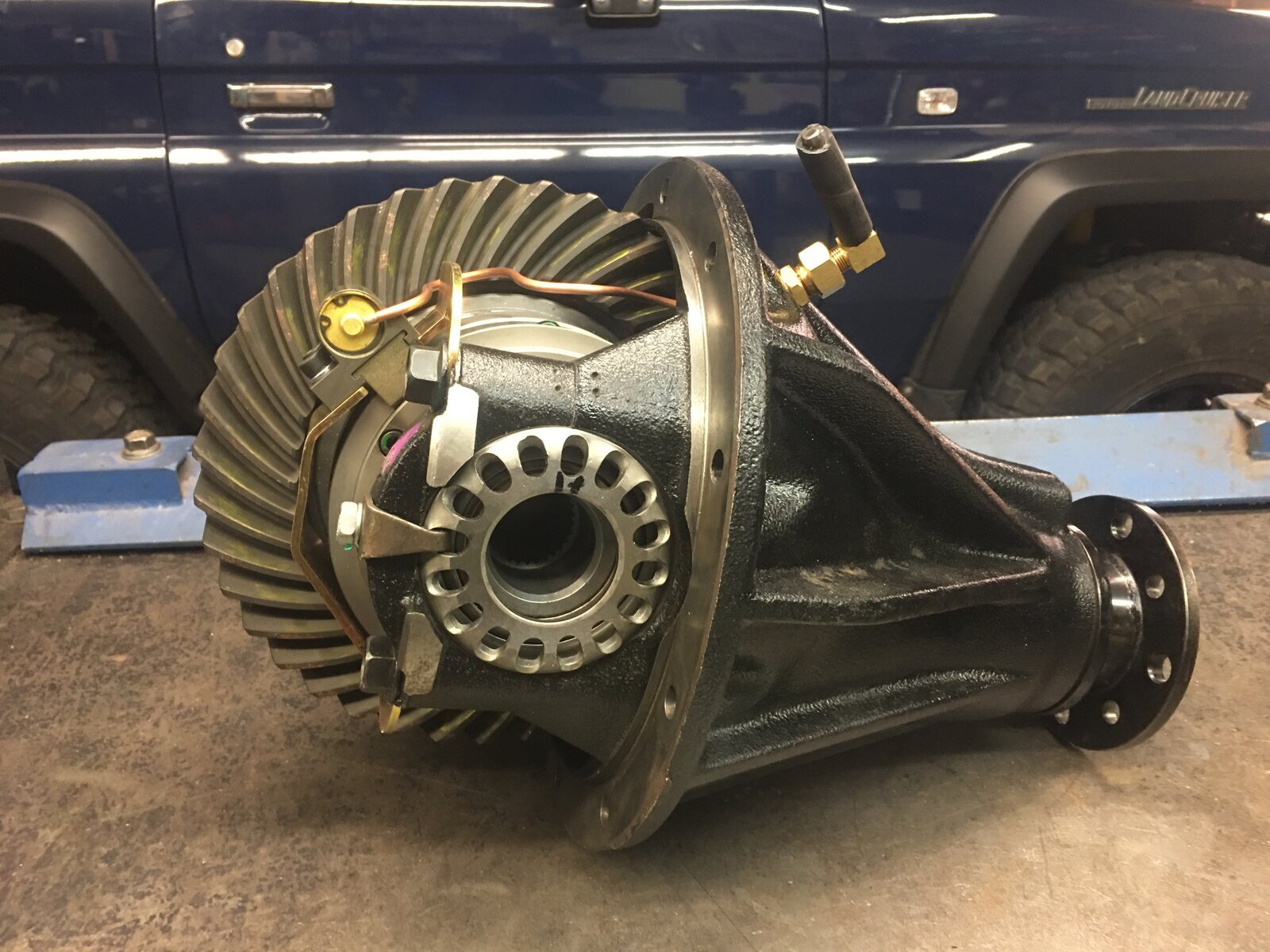

The 100 series diff centre got fitted with a TJM Pro Locker (the best locker available) along with a solid pinion spacer and new 4:88 ring and pinion.

The diff guy also checked and adjusted the housing on his hydraulic press because the heat of welding the brackets on had distorted it slightly.

I then printed it with etch primer followed by 2K primer and 2K satin black.

Re-assembled it all.

Filled it with oil.

And refitted it to the vehicle.

Being the Pro Locker is air operated, I needed to hard mount a compressor. I’ve always just carried a portable 12v compressor in the 78 in the past, for tyre inflating, but those days were over.

I considered using an ARB twin cylinder compressor as we fit them a lot at work, as in Australia at least, they’re regarded as the best 12v compressors you can buy.

But to save some money I decided to use a 12v compressor I got free from work, years ago.

I made a mount to fit it under the passenger front seat.

And that was that job done.

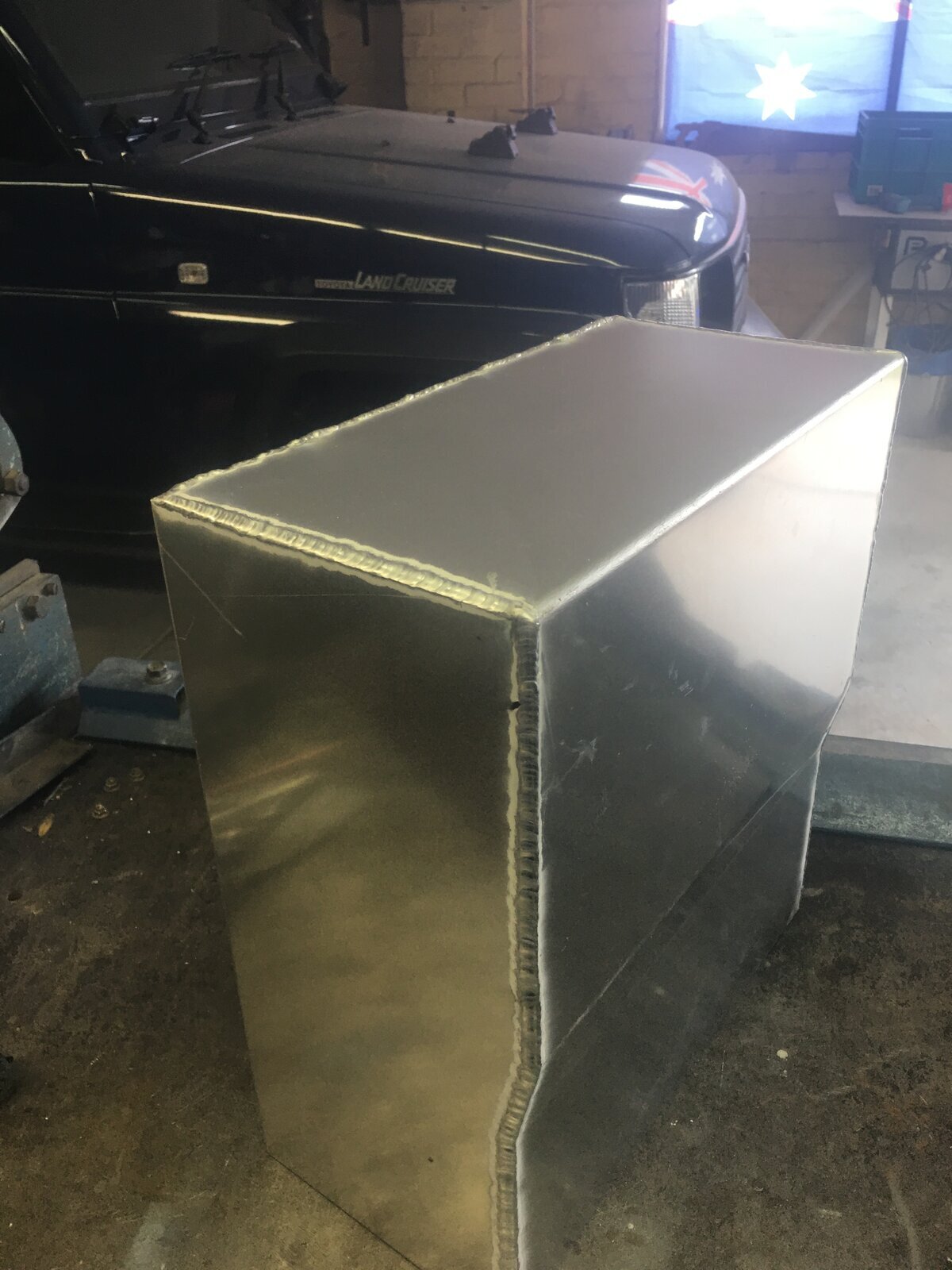

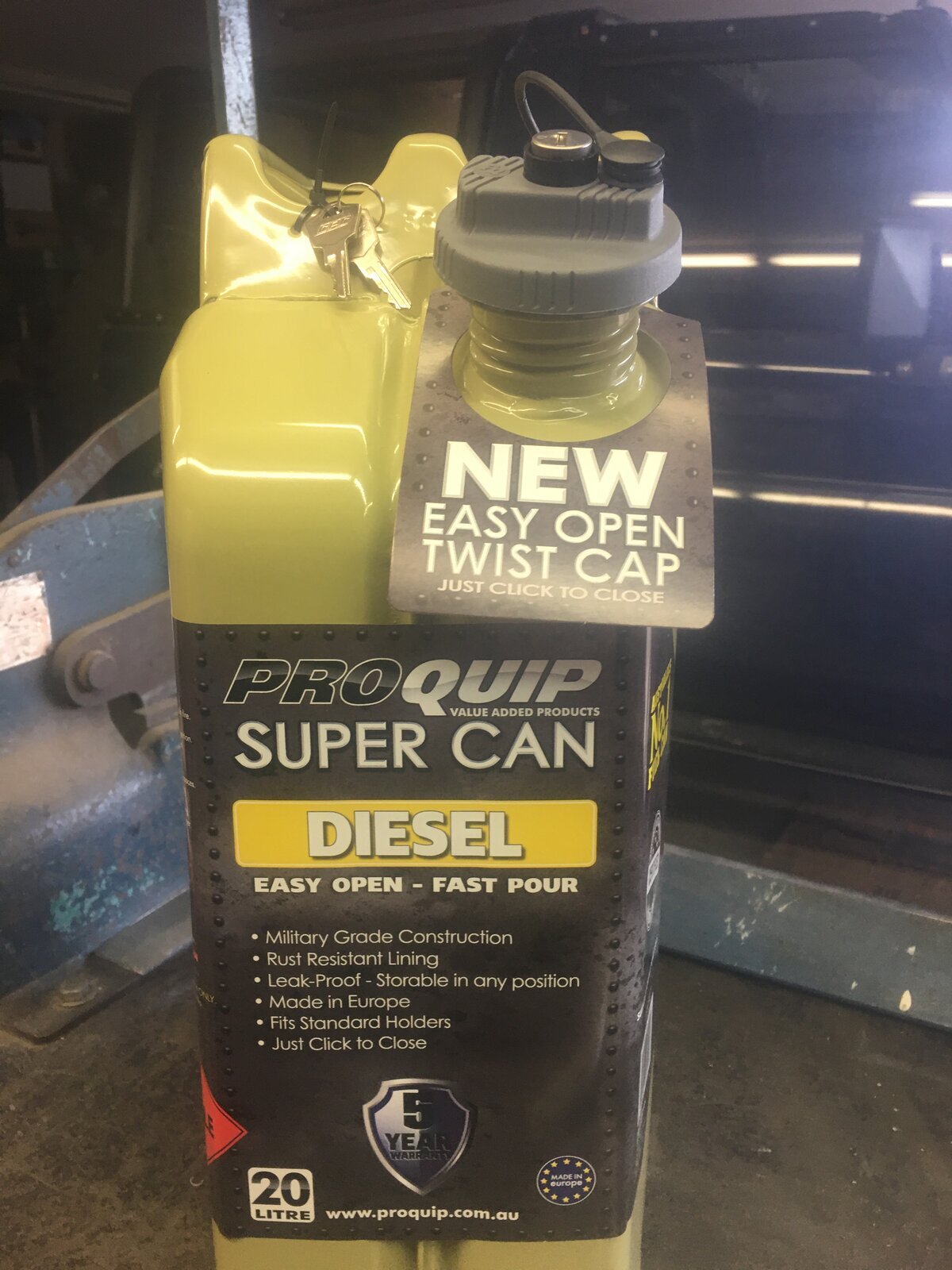

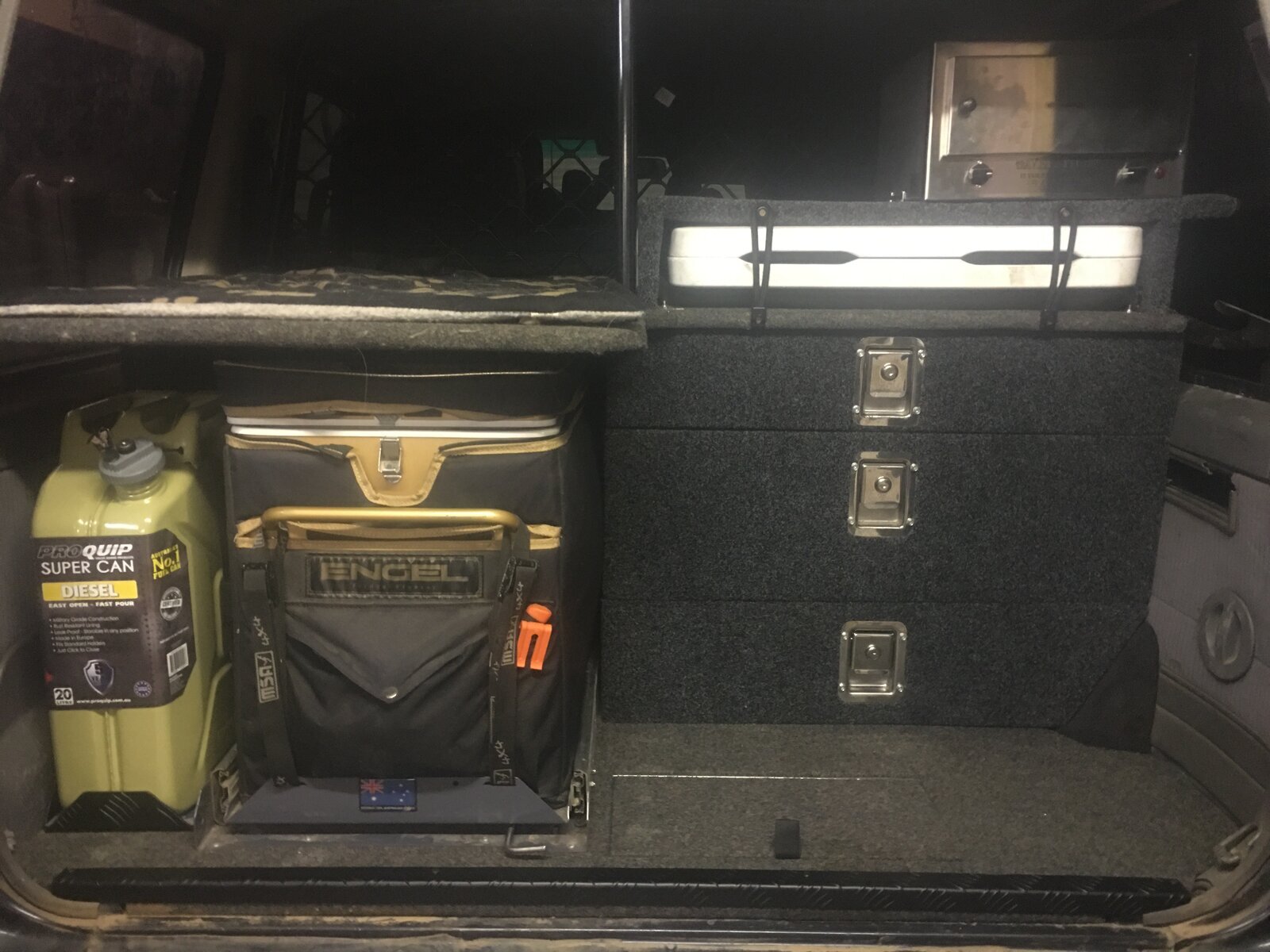

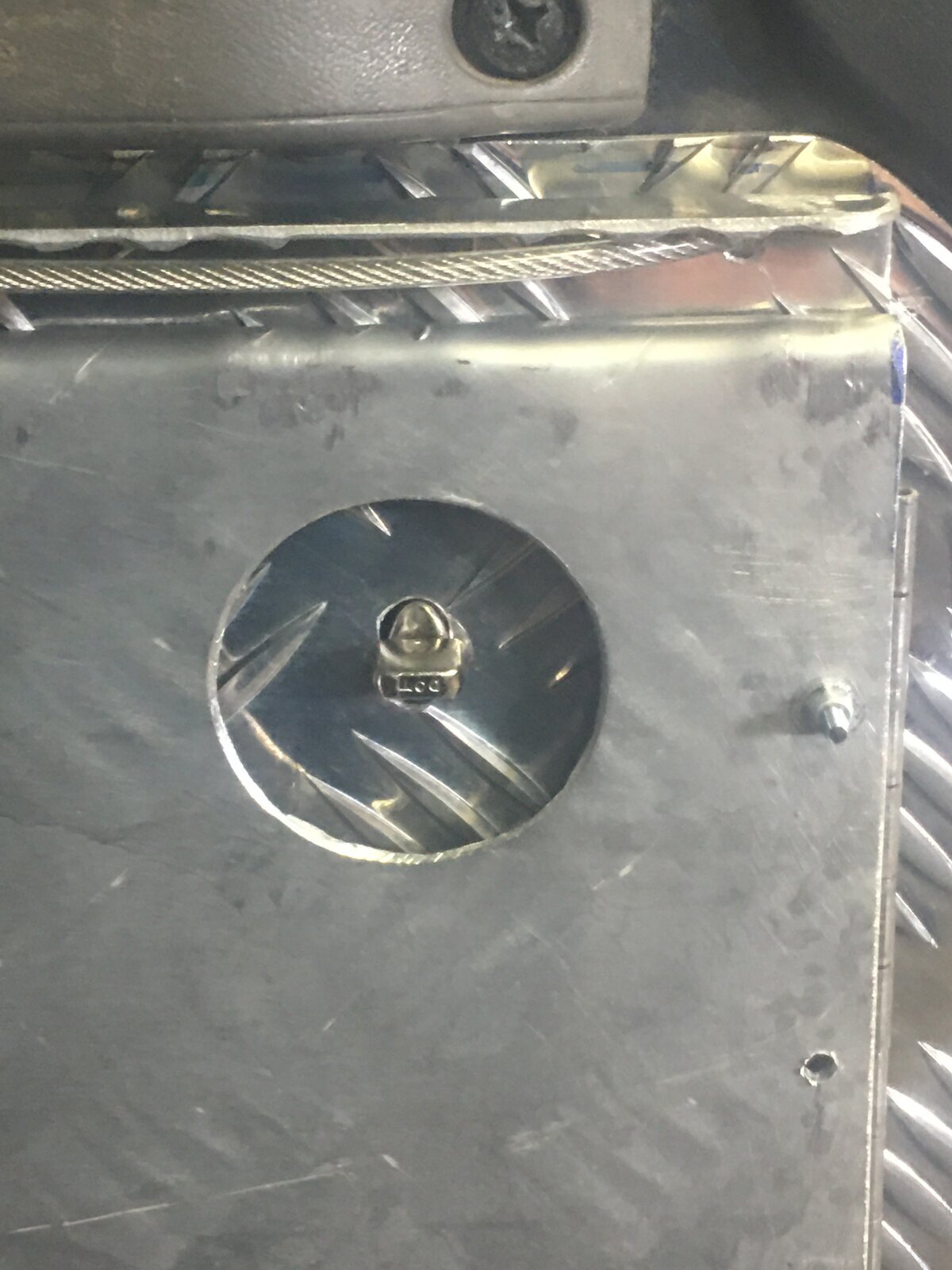

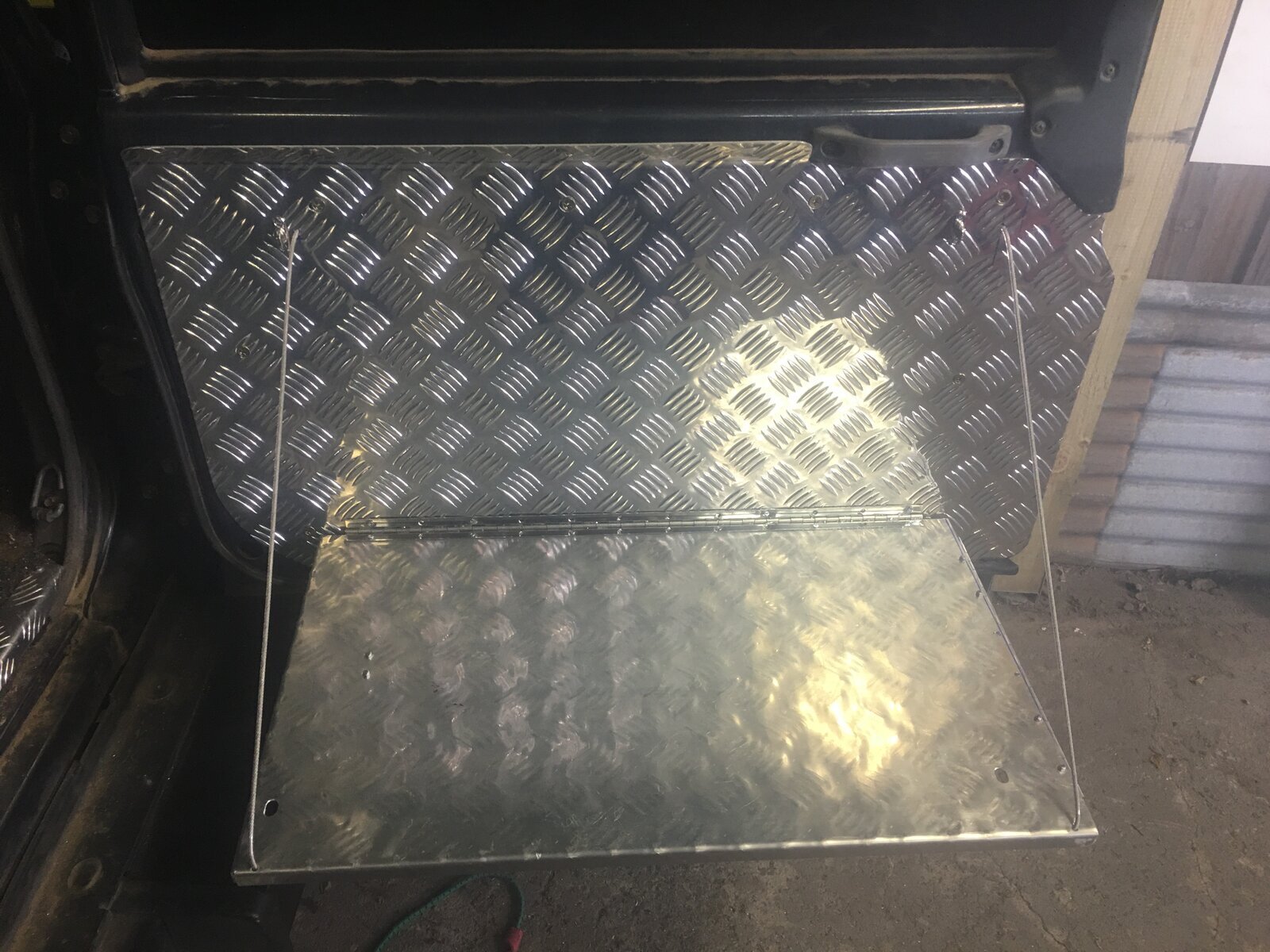

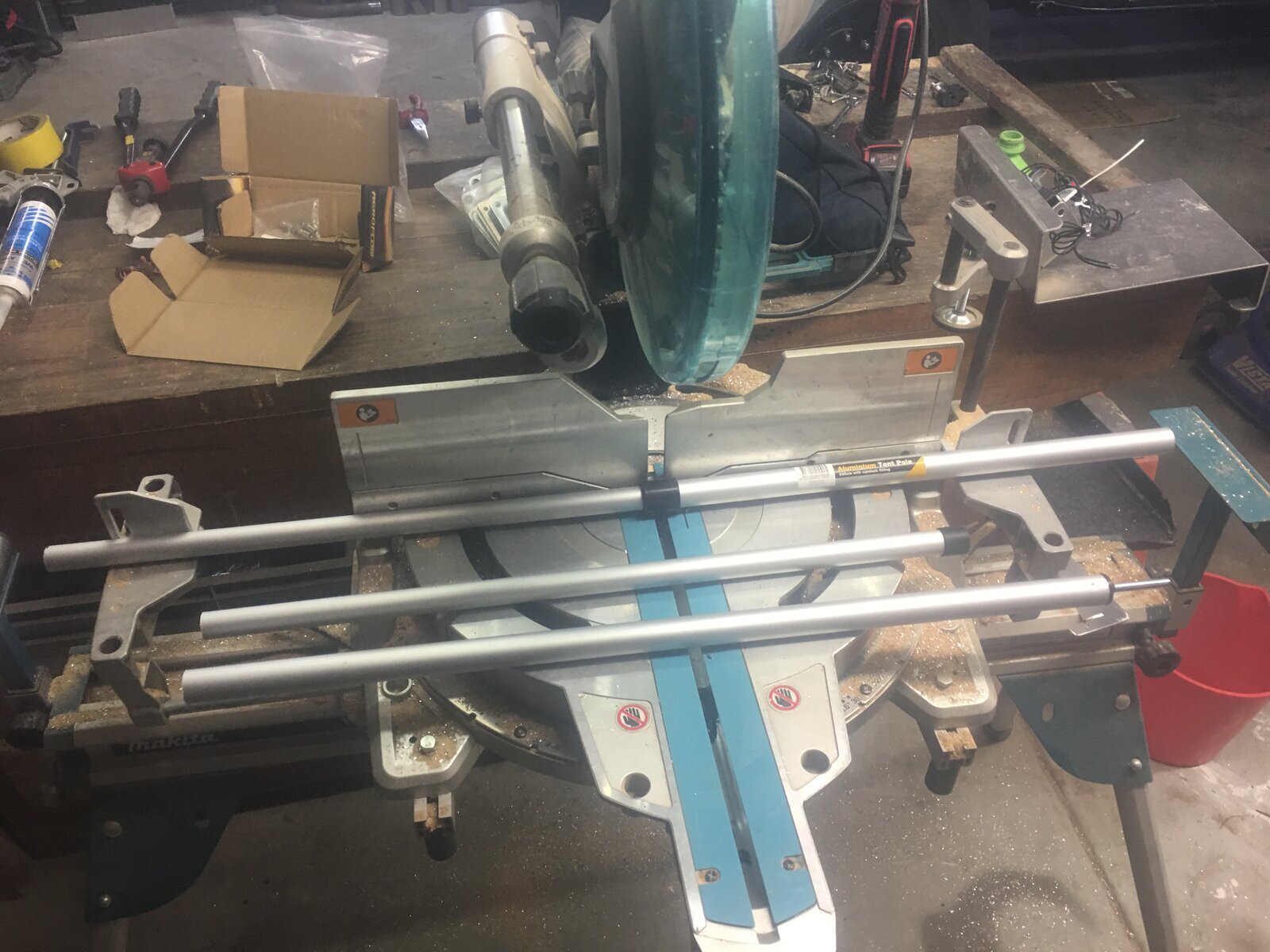

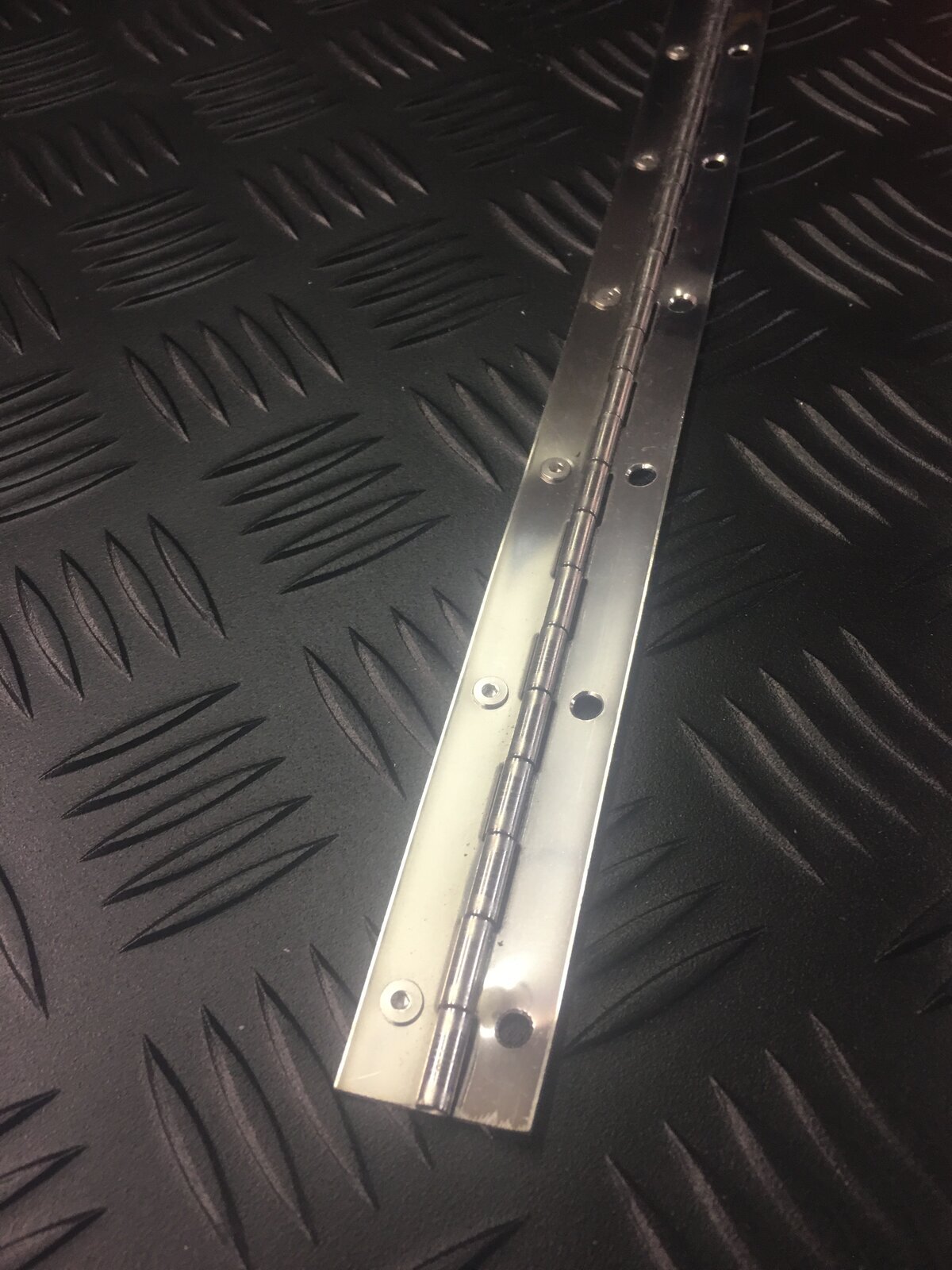

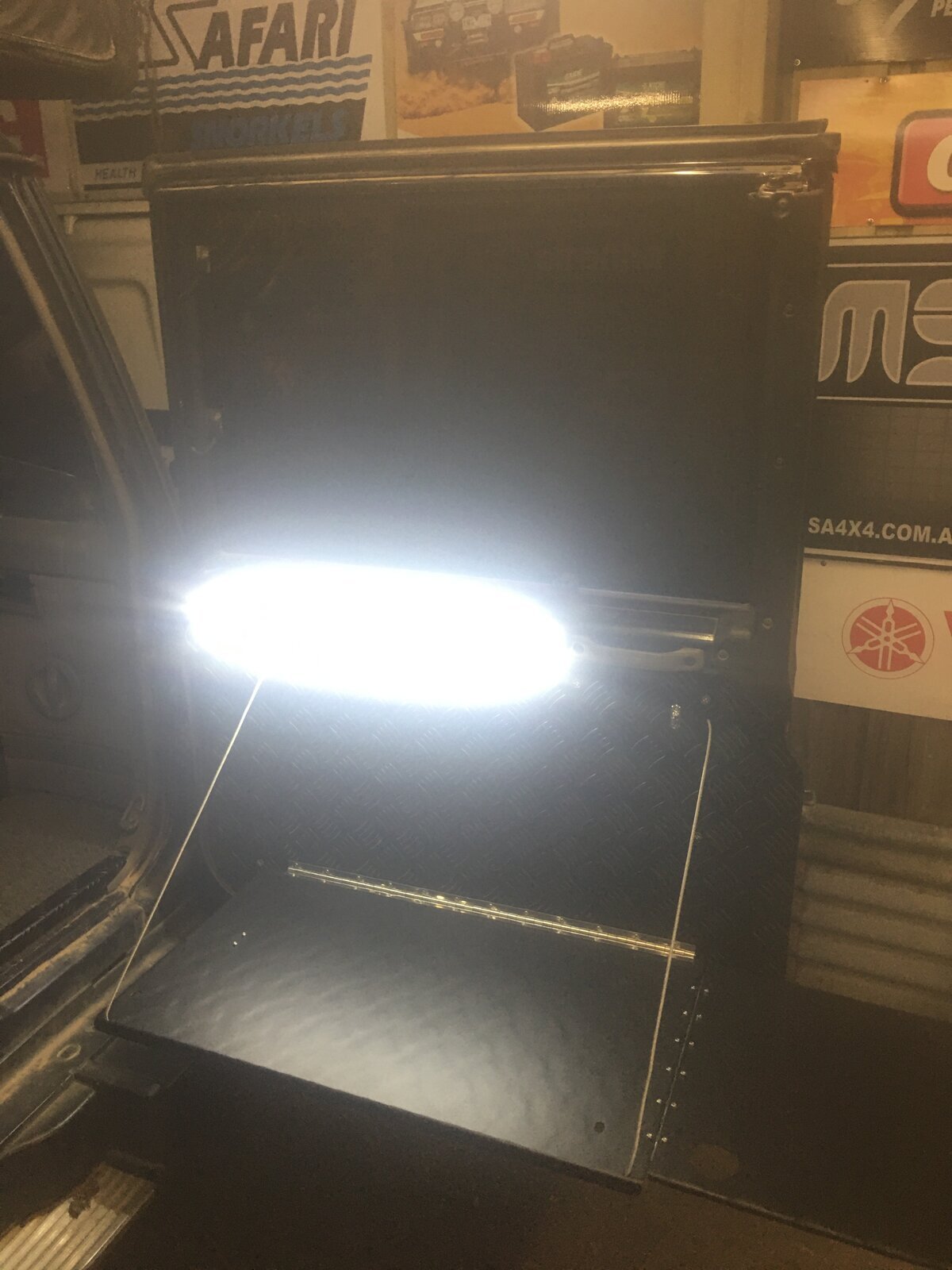

Table and fuel can update coming next…..

2021-06-13 13.34.48 by Vc1r, on Flickr

2021-06-13 13.34.48 by Vc1r, on Flickr 2021-12-19 13.04.54 by Vc1r, on Flickr

2021-12-19 13.04.54 by Vc1r, on Flickr Something weird there. Their tools section was kiddie in a sweet shop stuff.

Something weird there. Their tools section was kiddie in a sweet shop stuff.

However mine is 5.29 instead of the stock 4.88, so one less tooth on the Pinion i believe..

2021-06-13 13.34.48 by Vc1r, on Flickr

Gotta Flip that pumpkin for right side offset

2021-12-19 13.04.54 by Vc1r, on Flickr

Looks like you’ve been busy.

Something weird there. Their tools section was kiddie in a sweet shop stuff.