Had a go at rebuilding my rear diff locker on Sunday, cleaned up fine and inside wasn't that bad. With it in bits, I noticed a lot of galvanic corrosion between the steel motor cover (held on with 3 screws) and the actuator body. All I could do with it was clean it back to solid aluminium again and bridge the gap ive now created with gasket sealant.

With everything cleaned and greased, it went back on the car, with no joy. Tried plugging it onto the front and still nothing. Took the gears/springs out, but motor still didn't move.

Then last night (while falling asleep of all times) it occurred to me that ive tightened up the cover cap up hard onto the motor. Back home after work today, straight under the truck, loosened the screws, BAM it turns!

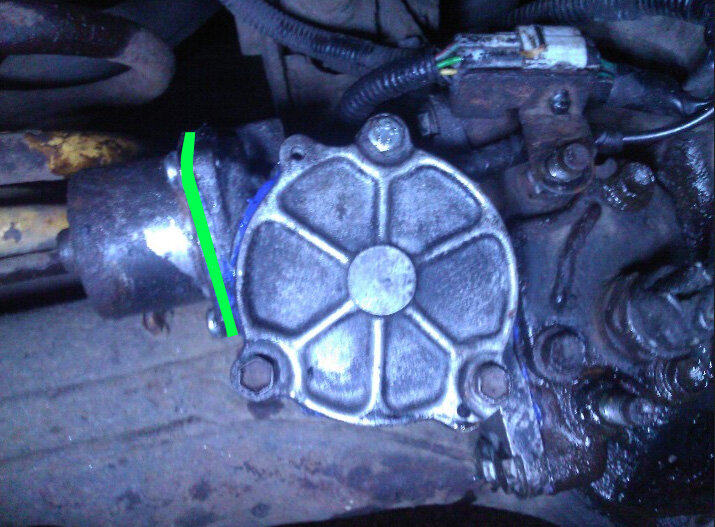

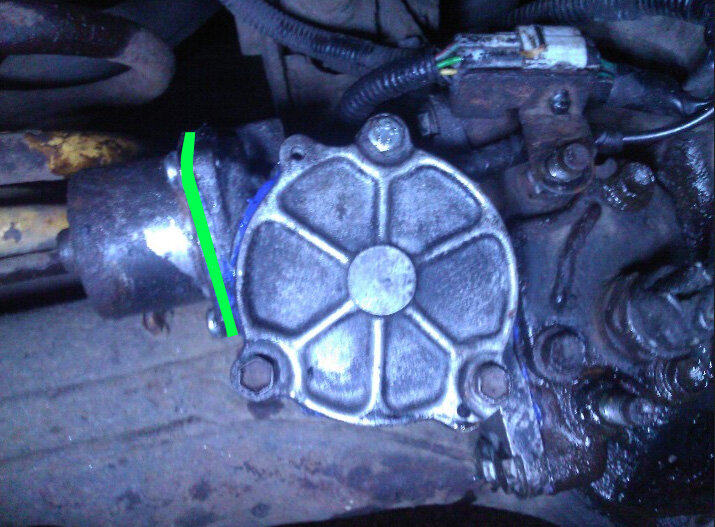

The gap in question is in green here. Because ive lost a few mm of aluminium, it closed up on the motor too much. So tomorrow I will go about making up a rubber gasket to open it up abit.

Thought id throw in my 2p worth of experience. Cant find this problem/solution anywhere else.

With everything cleaned and greased, it went back on the car, with no joy. Tried plugging it onto the front and still nothing. Took the gears/springs out, but motor still didn't move.

Then last night (while falling asleep of all times) it occurred to me that ive tightened up the cover cap up hard onto the motor. Back home after work today, straight under the truck, loosened the screws, BAM it turns!

The gap in question is in green here. Because ive lost a few mm of aluminium, it closed up on the motor too much. So tomorrow I will go about making up a rubber gasket to open it up abit.

Thought id throw in my 2p worth of experience. Cant find this problem/solution anywhere else.