Beau

Well-Known Member

- Joined

- Jan 28, 2011

- Messages

- 2,014

- Country Flag

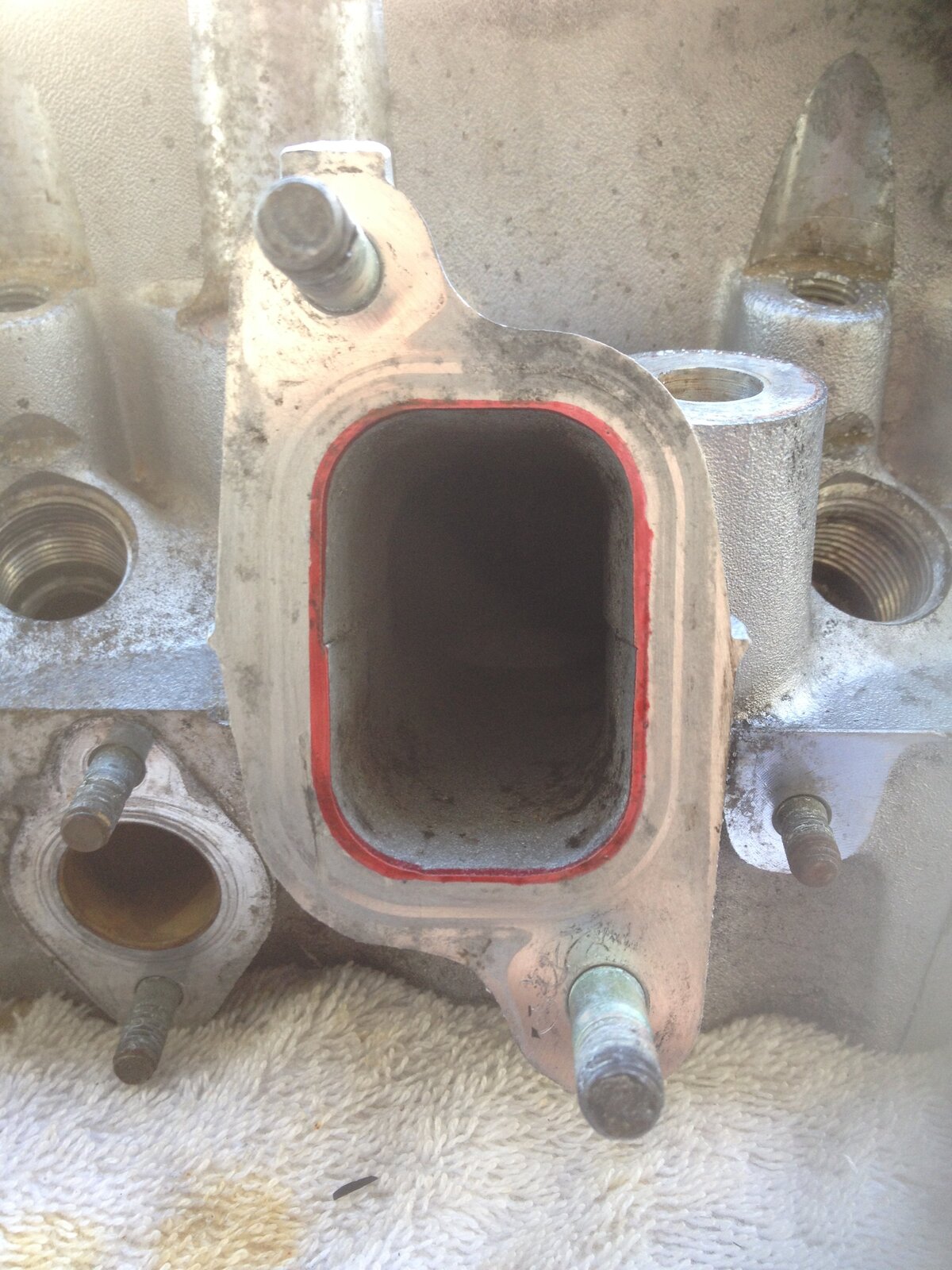

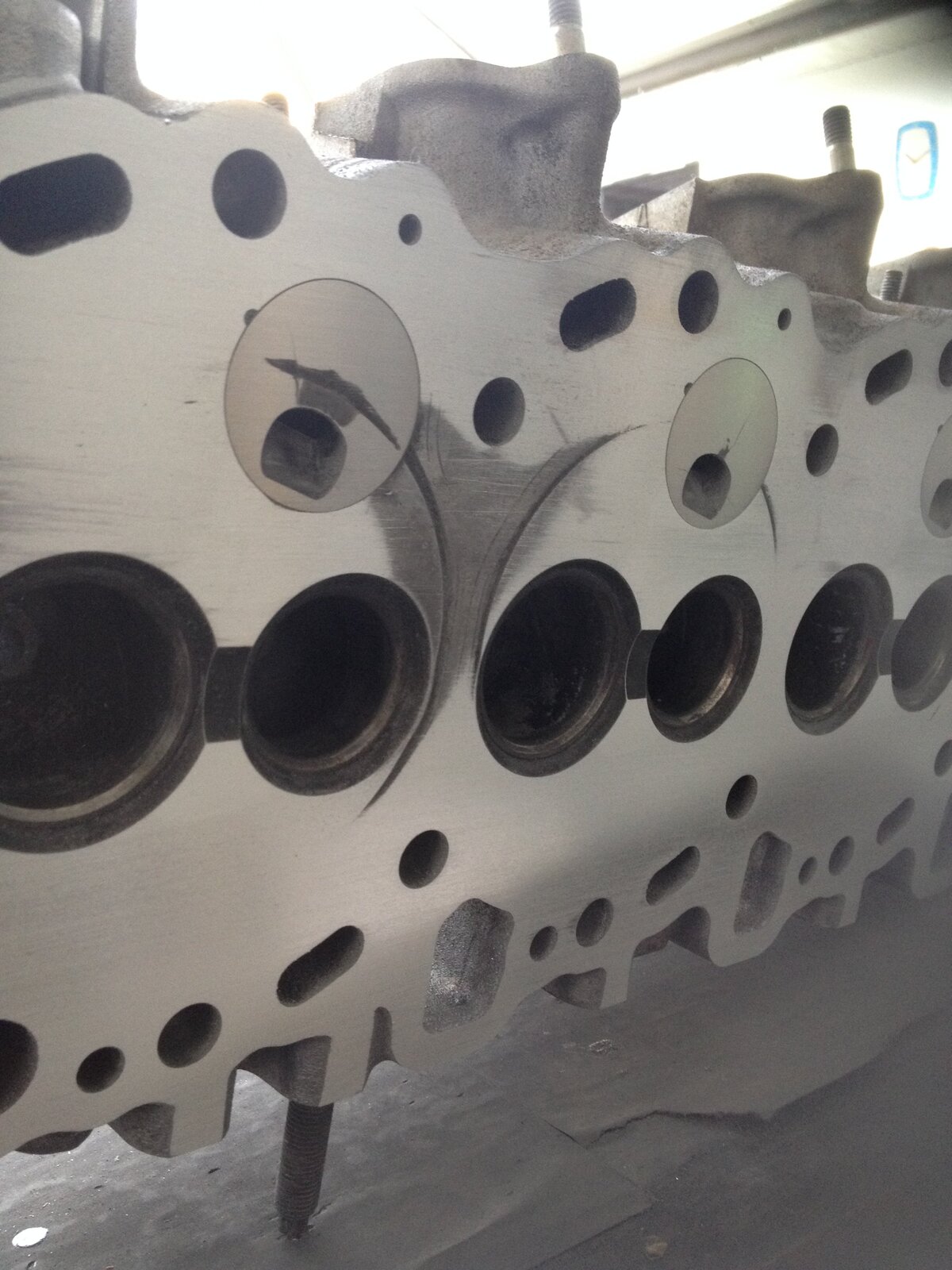

Unfortunately not, however the guy I spoke to test it for leaks by sealing the head and then submerging it in water. He then pressurizes the head and looks for air bubbles. It's a pretty bulletproof method I think...

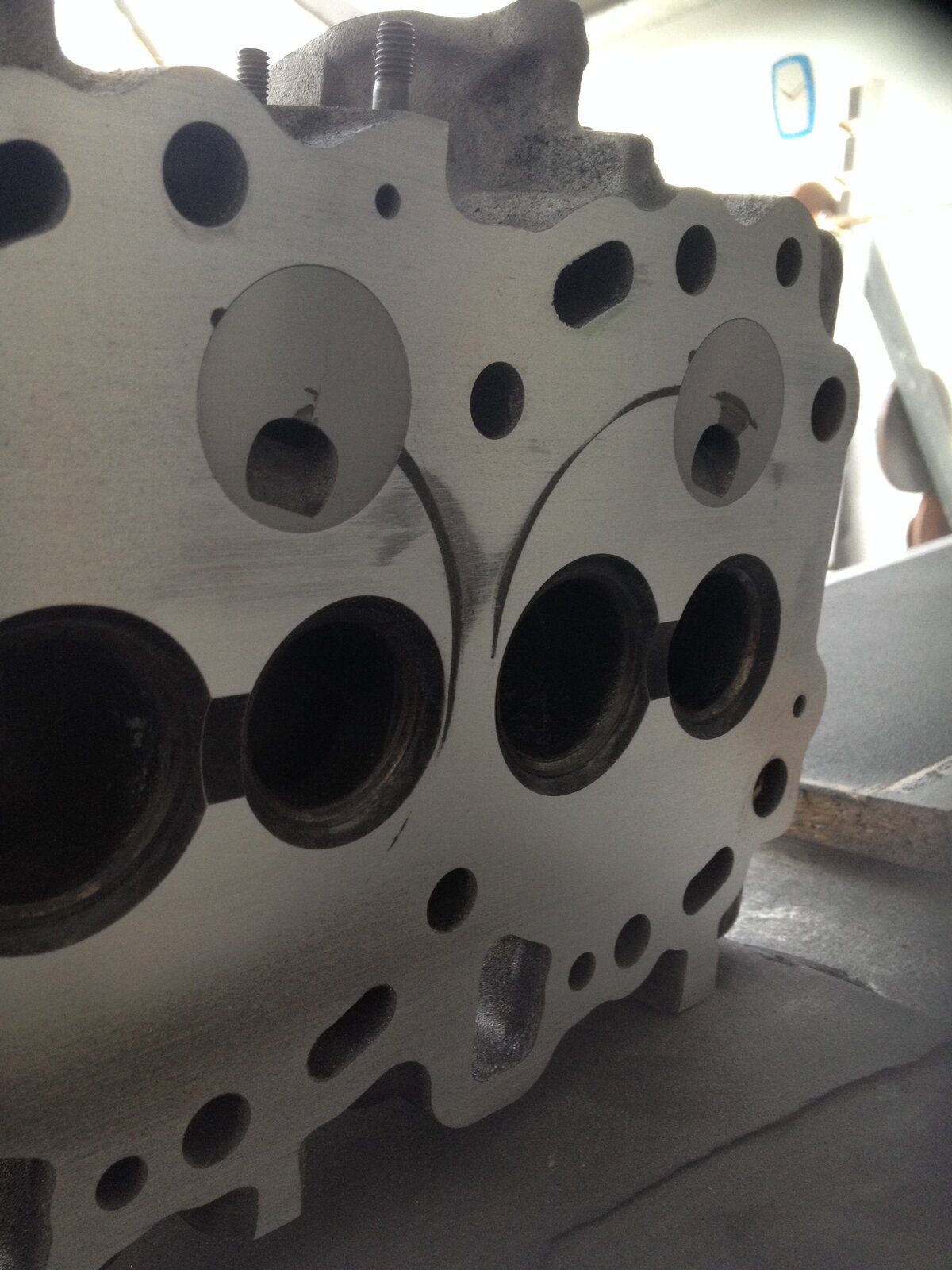

The plan was to initially tighten it down, but not to torque spec, just tight. Once warm I would re-tight it further. Shayne, yeah it's a pretty old school approach but it works. And like you said, I have nothing to lose. I'm quite looking forward to seeing how it goes. Will definitely take pics for you guys.

The plan was to initially tighten it down, but not to torque spec, just tight. Once warm I would re-tight it further. Shayne, yeah it's a pretty old school approach but it works. And like you said, I have nothing to lose. I'm quite looking forward to seeing how it goes. Will definitely take pics for you guys.

well done for trying and bravo on your success

well done for trying and bravo on your success

.

.