BRE Fabrications LTD

Well-Known Member

I used parts from big red for my recent brake rebuild. Parts all seemed good. Prices were decent too.

Gary I notice non-OEM Toyota parts there. Is that brand any good?

Just managed to change out the front disks and pads before the heavens opened.

Snap, did the front disks and pads today. Also changed the pins, anti-rattle plates and the spring thing... nice and shiny now and the pulsing when braking has now gone. Not too much trauma, although one of the pistons was sticking a bit so pushed it out as far as I could cleaned it up and used some Toyota red grease, all back together working nice.

View attachment 101990

View attachment 101991

I also bought disks and pads for the rear, but they are still fine, so will save them for probably next year.

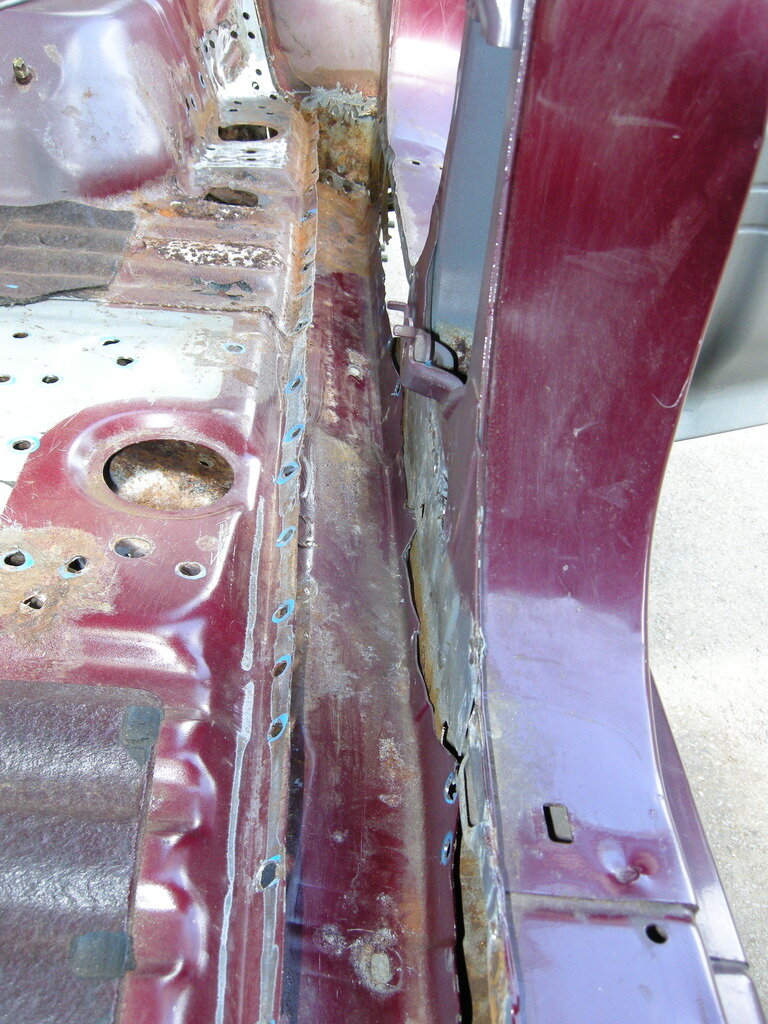

Today was a day of preparation of rhe hj60 before going in for welding and derusting of bodywork.Snap, did the front disks and pads today. Also changed the pins, anti-rattle plates and the spring thing... nice and shiny now and the pulsing when braking has now gone. Not too much trauma, although one of the pistons was sticking a bit so pushed it out as far as I could cleaned it up and used some Toyota red grease, all back together working nice.

View attachment 101990

View attachment 101991

I also bought disks and pads for the rear, but they are still fine, so will save them for probably next year.

Took the 24V auto for its MOT today which it passed no advises. Not bad for an old smoker I bought a year ago and virtually hadn't touched just used.

Treated it to a partial auto fluid change ( drained 4L out and replaced it) and flushed the PAS out too and gave it new fluid. TBF the PAS fluid wasn't bad but the auto box fluid was like brown paint. However it ran perfectly on it and it ran perfectly on what I replaced it with so we will see.

.

.