EldoradoSAM

Active Member

- Joined

- Oct 30, 2018

- Messages

- 67

- Country Flag

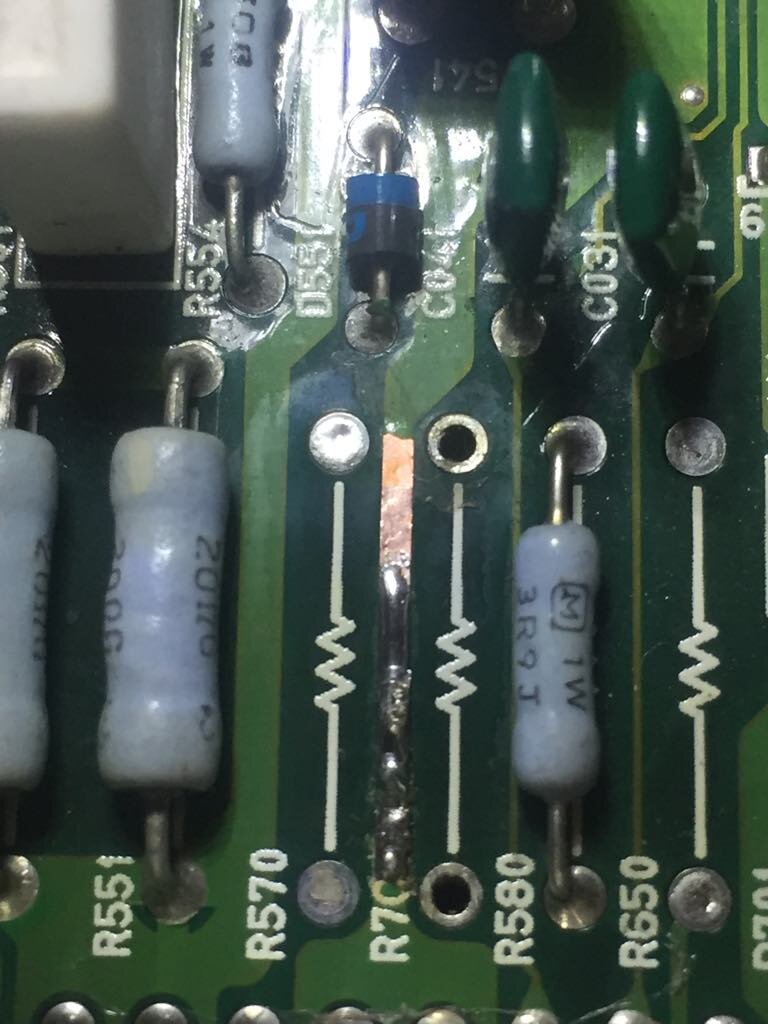

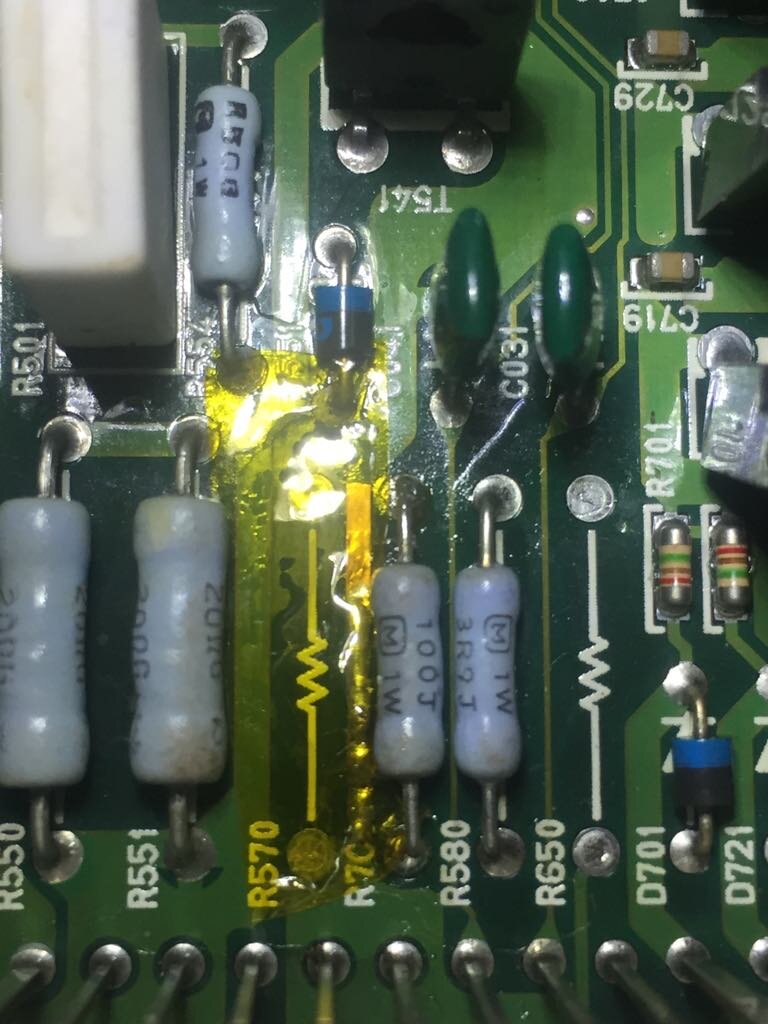

I’m currently working on the ECU. And here’s what I’ve found. Will try to repair it....

SC,no fault codes showed up. I'm thinking it was that short in the alternator fuse..Ok, smoking gun there Sam. There’s more to this than meets the eye. Not sure if this is a known problem (did you read it?) or something that’s got shorted in the rebuild?

Once you’ve done what you need to with the transmission and got it filled back up, testing the alternator is easy for a basic test. Set your multimeter to DC volts and test across the battery terminals. After start you should see 14.4V no more. At the alternator terminal it may be a few tenths higher. Do the same on AC volts and you should get no significant reading. If you do get a voltage your diodes in your alternator are faulty but this usually means your battery will drain quickly. Higher volts will usually boil the battery.

On the blown track, simply clean up the copper track either side of the break and solder a piece of copper wire across. This can be bare solid of at least the same cross sectional area as the track.

Before you reconnect this, trace the terminal and the wire it connects to. See where it goes and check there is no damage. A damaged loom could be the cause of your problems. This could also be a route for the solenoid ground to return via something it shouldn’t and burn the track. It’s quite important to try and work out why this has happened so that no more damage is done. It’s great if you fix it, put it back and it all works but it’s peace of mind knowing that you’ve found what caused it in the first place and you’ve cleared that also.

SC, where the track was broken, I did put a copper strand the same size as the track then soldered it to the track. (Removed the copper from another motherboard and cut it to size) Might look like solder alone but I can assure you there is more there.Sounding more like an alternator diode fault as we go on. The fuse will not be the fault, rather an indication there is a fault which needs to be rectified (no pun intended), probably a shorted diode in this case. Though tempting, it’s rarely a good idea to simply replace a blown fuse and call it job done without doing some tests to find what has caused it to blow.

The track might be ok but really needs a strand of 1mm copper wire or similar laid on top well over the ends of the track and soldered rather than just solder (forgive me if that’s what you’ve done it just doesn’t look like it from the pic). Like the tape by the way, not 100% needed but good to have. Spray lacquer would do as the original purpose of the green in resisting solder in manufacture is passed.

The initial fuse blowing on the alternator should have raised the question ‘why?’, instead it was bridged, presumably with something that would not have fused, and the alternator, and its fault, were then reintroduced to the system, sending alternating current into the wiring and causing damage to electronic circuits.

To test for a bad diode, with engine at rest, disconnect the alternator main terminal and test on ohms between that terminal and the casing. Then reverse your test leads and test again. One way should show no connection. If both show a low reading you have one or more diodes gone short circuit.

As shown here, though they use the diode test setting on the multimeter which does the same thing.

![GPSO9717[1].JPG GPSO9717[1].JPG](https://www.landcruiserclub.net/community/data/attachments/157/157469-550d153d3b7e235707a161ba7a149f49.jpg?hash=VQ0VPTt-I1)

Beau, I think it was that bridged alternator fuse. Strands of some gauge wire was used and it seems with the rough terrain it might have started breaking a while now. when it was down to a few strands it would cause a fluctuation of current from vibrations on the vehicle while off-road. Just a thought... Or could of been that earth wire you spoke of...Well I hope that fixes your problem although I still think your symptoms sounds more mechanical. As SC has said, it's good knowing what's caused that thing to burn out like that in the ECU so it doesn't happen again. 13.8 volts from these alternators sounds alright, a bit on the low side. I think last time I checked mine I was getting a solid 14.2.

SC, that alternator fuse was already bridged when I got the car back after the rebuild. Also that earth wire @Beau pointed out was also cut.It’s the fuse blowing that’s of concern, your evidence if you like.

What results did you get with the diode test? You can test each one now you’ve replaced them and see if they’re dud.

Yes, I did get this from your earlier post. What I’m saying is that a fuse blowing isn’t ‘the fault’. It is an indication that something else is wrong that needs finding and putting right. A bridged fuse is worse because it often means the fault that caused it to blow hasn’t been corrected and the bridge is unlikely to blow, in this case sending alternating current into your car’s electrical system to do all sorts of damage. It is likely responsible for some if not all of the damage you’ve sustained.SC, that alternator fuse was already bridged when I got the car back after the rebuild.

But he did say if it doesn’t pass the diode test the diode pack is faulty which is what was suspected here. My point being to test first and react on the results rather than blindly change components. In your case the diode pack is faulty and replacing both that and the regulator is a good move as your alternator is now refurbished. As long as the bearings are good, this should give it a new lease of life.As for the diode test. Guy in that video said, "just because it passes this test doesn't mean it's good".

Try and get genuine Toyota, you don’t want a repeat of this. Also if buying from abroad do you have import tax to factor into the cost where you are? This may be different depending on where you source the parts from. Amayama.com Partsouq or Megazip are genuine parts suppliers who ship all over the world.One place quoted me a price of $100 usd for the trans solenoid. I thought that was a bit high, if i don't get it elsewhere I'll buy it. Found the entire kit on ebay from the USA for $76usd....(3solenoids,filter,gasket) https://www.ebay.com/itm/Transmission-Solenoid-Set-A340E-A343F-TCC-Shift-Filter-Kit-For-Toyota-Lexus/132560777075?_trkparms=aid=111001&algo=REC.SEED&ao=1&asc=20160811114145&meid=20bfa2cdf78a463aac4f32e3e42f330b&pid=100667&rk=2&rkt=6&sd=113007027533&itm=132560777075&pg=2045573&_trksid=p2045573.c100667.m2042

Import tax isn't that much on parts. And I usually use a drop shipper in the USA.Also if buying from abroad do you have import tax to factor into the cost where you are?

It was definitely faulty..In your case the diode pack is faulty

Well I really hope not, but after a closer look at the filter there is a chance of more. And Thanks. Positive Energy always helps.I just hope the black in the oil isn’t an indication something has worn badly so I have my fingers crossed for you.

I hope there isn't Beau.. We'll see when I get the solenoid and put it all back.I hope there isn't further damage done. In my opinion, I think there is from how the truck behaves.

Its every start. If I hold the key when starting it takes about 3 seconds or so to start. If I let go of the key and turn again it starts right away.Question, is it every start, or just cold start?