SteveS

Well-Known Member

- Joined

- Jan 12, 2013

- Messages

- 630

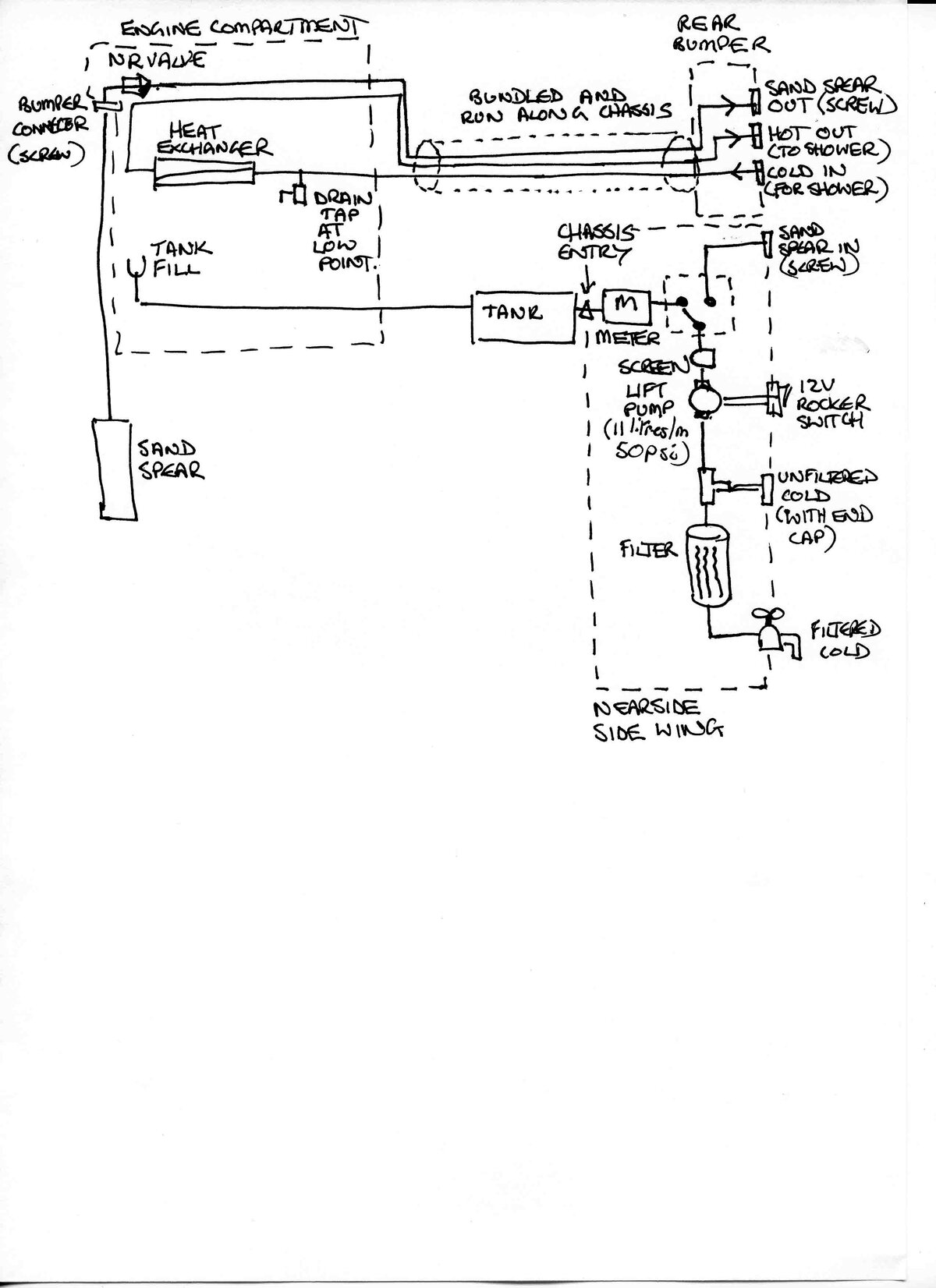

Also selected the water purification and filtration system to use. I will use the Nature Pure Seagull IV X-1B model which comes without faucet. I will just have a simple outlet pipe and tap. This model is small enough to mount under the drawer side wings along with the pump and water metering/counter, hoses and electrics. This one is a job for next month......

http://www.purewateronline.co.uk/700008-X-1B-Seagull-R-IV-Basic.html

http://www.purewateronline.co.uk/700008-X-1B-Seagull-R-IV-Basic.html

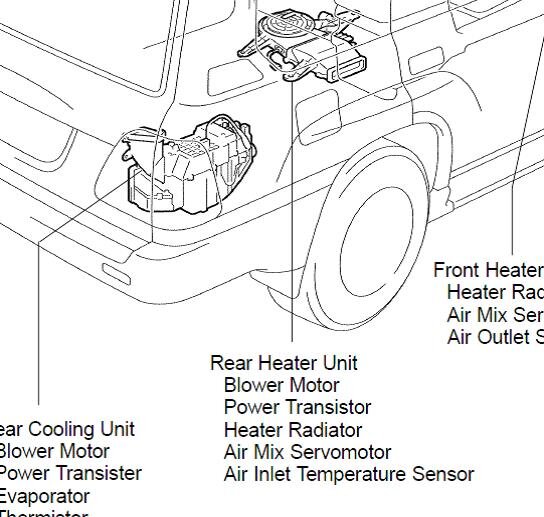

)...only the heater under the seat. I'm guessing the 2nd heater matrix feed pipes come into the vehicle shell rather than the heater matrix connections poking out through the floor - thoughts? Do you know if they are metal or rubber pipes under the truck/through the floor to the heater??

)...only the heater under the seat. I'm guessing the 2nd heater matrix feed pipes come into the vehicle shell rather than the heater matrix connections poking out through the floor - thoughts? Do you know if they are metal or rubber pipes under the truck/through the floor to the heater??